Robot parts

Showing all 16 results

- Robot parts

5-Axis CNC Machined AI Robot Complex Joint Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

5-Axis CNC Machining of High Quality Robotic Arm Joints

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

CNC Machining Creates Flexible Humanoid Robot Hand

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

CNC Machining For Ai Robotic Dog Electronic Robots Dog

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

CNC Machining For Boston Dynamics’ Spot Robot Dog

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

CNC Machining For RC Walking Dog Toy – AI‑Powered

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

CNC Machining For Unitree G1 Humanoid Robot

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

CNC Machining Of Custom Intelligent Humanoid Robot Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

Custom 5 Axis CNC Machined Parts for Robot Arm Joints

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Custom 6 Axis CNC Machining Industrial Robot Arm Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Custom CNC Machining & Turning – Your CNC Expert for Robotics & Automotive

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Mobile Industrial Robots A/S – Drives Growth With CNC

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

OEM CNC‑Machined Titanium Alloy Robot Arm Joints

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision CNC Aluminum Prototype Shells for Humanoid Robots

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Storeroom Industrial Robotics Phoenix By CNC Machining

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

Uesd Robot Coupe CL50 Parts OEM Steel Robotics Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing 1–24 of 147 results

- Aluminum Alloy CNC Processing

3/4/5 Axis Rapid Prototyping for Aluminum Alloy Metal Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

5-Axis CNC Machined AI Robot Complex Joint Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Robot parts

5-Axis CNC Machining of High Quality Robotic Arm Joints

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6061 Aluminum Parts CNC Machining Service OEM

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6061-t6 Aluminum CNC Machining Factory Custom Aluminum Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6082 Aluminium Alloy Precision CNC Machining Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

ABS Engineering Plastic Precision Parts CNC Machining

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

ABS+PC Hubcap Wheel Cover 15 Inch for Tesla Model 3

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminium Cnc Machining China Custom Source Factory

$0.30Rated 0 out of 5 - Aluminum Alloy CNC Processing

Aluminum Alloy 4032 CNC Precision Machined Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Aluminum Alloy 6063 T5 CNC Machined Parts – Precision Custom

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Aluminum Alloy 7075 Precision CNC Machined Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

Aluminum Alloy Access Control Panel Enclosure (CNC Machined)

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminum Alloy CNC Processing + Black Oxidation

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminum Vs Stainless Steel CNC Lathing Machining Service

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Auto Parts Milling Turning Machining CNC Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Auto Parts Processing Service Supplier Precision CNC Machined

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Automotive Engine Oil Pan CNC Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Brass Precision Parts CNC Machining

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

China Stainless Steel Cnc Machining Factory

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing 1–24 of 33 results

- Aluminum Alloy CNC Processing

3/4/5 Axis Rapid Prototyping for Aluminum Alloy Metal Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

China Stainless Steel Cnc Machining Factory

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

CNC Machining for Electric Motor Stator Rotor

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Metal

CNC Machining Services: 25mmx1mm Metal Slug

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Metal

CNC Machining Services: Ductile Cast Iron CNC Machined Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Metal

Custom CNC Aluminium Machining Set – Prototype Metal Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Custom CNC‑Machined Motorcycle Engine Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Metal

Custom Quality Aluminum Stainless Steel Brass Machining

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Golden Valley Auto Parts And Hardware CNC Machining

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

High-Precision Custom CNC Lathe Fixtures OEM CNC Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Machining Service Aluminum Cnc Milling Mechanical Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Metal

Metal Machining Parts Cnc Aluminium Cnc Machining

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Motorcycle Parts 5 Axis CNC Machining Service

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

OEM CNC Machining China for Stainless Steel Cnc Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

Precision 5 Axis CNC Parts – Your Partner for Complex Metal Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing 1–24 of 35 results

- Aluminum Alloy CNC Processing

3/4/5 Axis Rapid Prototyping for Aluminum Alloy Metal Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6061 Aluminum Parts CNC Machining Service OEM

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6061-t6 Aluminum CNC Machining Factory Custom Aluminum Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6082 Aluminium Alloy Precision CNC Machining Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminium Cnc Machining China Custom Source Factory

$0.30Rated 0 out of 5 - Aluminum Alloy CNC Processing

Aluminum Alloy 4032 CNC Precision Machined Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Aluminum Alloy 6063 T5 CNC Machined Parts – Precision Custom

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Aluminum Alloy 7075 Precision CNC Machined Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminum Alloy CNC Processing + Black Oxidation

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminum Vs Stainless Steel CNC Lathing Machining Service

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Machining Services: 6061 6063 CNC Aluminum Part Factories

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

CNC Machining Services: Auto Parts Suppliers Harrisburg Pennsylvania

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Machining Services: Honda Aluminum Wheel 42700-S5N-A91

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom Keyboard 3Ds Cia & CNC Machined Keyboard Cases

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

High-Precision Custom CNC Lathe Fixtures OEM CNC Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Iphone 17 Prototype CNC Machining: Display Prototype

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Machining Service Aluminum Cnc Milling Mechanical Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Motorcycle Parts 5 Axis CNC Machining Service

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

OEM CNC Machining China for Stainless Steel Cnc Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 23 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Brass Precision Parts CNC Machining

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

CNC Machining Bronze Precision Prototype Manufacturing

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

CNC Machining Services: Field King 181870 Brass Nozzles Kit

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom Keyboard 3Ds Cia & CNC Machined Keyboard Cases

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Copper Parts CNC Processing

Custom Made CNC Brass Machining Turned Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Copper Parts CNC Processing

Factory Supply Brass CNC Turned Components

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

High-Precision Custom CNC Lathe Fixtures OEM CNC Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Machining Service Aluminum Cnc Milling Mechanical Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Mechanical Parts Dreamlight Valley CNC Machining Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Copper Parts CNC Processing

OEM ISO 9001 Precision Brass CNC Turned Parts Custom-Made

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

OEM Supply High Precision Brass CNC Machining Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Parts Of Stitching Machine CNC Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Copper Parts CNC Processing

Precision Brass CNC Machining Services 5 Axis CNC Milling

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Precision CNC Machined Beryllium Copper Components

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision Custom Machining Solutions – From Prototype to Production

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Red Copper Precision Parts CNC Machining

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 9 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision Custom Machining Solutions – From Prototype to Production

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 14 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

China Stainless Steel Cnc Machining Factory

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

High-Precision Custom CNC Lathe Fixtures OEM CNC Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

OEM CNC Machining China for Stainless Steel Cnc Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Alloy Steel

Precision CNC Machining Manufacturing Services – 5-Axis Lathe Capabilities

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision Custom Machining Solutions – From Prototype to Production

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Alloy Steel

Stainless Steel Cnc Machining Service Manufacturer

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 20 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminum Vs Stainless Steel CNC Lathing Machining Service

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

China Stainless Steel Cnc Machining Factory

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

CNC Machining Services: Bimba Stainless Steel 061-dxp

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom Keyboard 3Ds Cia & CNC Machined Keyboard Cases

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Steel

Custom Made Stainless Steel CNC Turning Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Golden Valley Auto Parts And Hardware CNC Machining

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

High-Precision Custom CNC Lathe Fixtures OEM CNC Machining Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Motorcycle Parts 5 Axis CNC Machining Service

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision Custom Machining Solutions – From Prototype to Production

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Alloy Steel

Stainless Steel Cnc Machining Service Manufacturer

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Stainless Steel CNC Machining Services – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Metal

Stainless Steel CNC Machining Services Machine Product Part

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 12 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

China Stainless Steel Cnc Machining Factory

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Golden Valley Auto Parts And Hardware CNC Machining

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision Custom Machining Solutions – From Prototype to Production

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Alloy Steel

Stainless Steel Cnc Machining Service Manufacturer

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 9 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Custom CNC Machining Factory’s for Micro Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision Custom Machining Solutions – From Prototype to Production

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 8 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

CNC Precision Machining Parts – CNC Machining Companies

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Precision Custom Machining Solutions – From Prototype to Production

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing 1–24 of 77 results

- Aluminum Alloy CNC Processing

3/4/5 Axis Rapid Prototyping for Aluminum Alloy Metal Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6061 Aluminum Parts CNC Machining Service OEM

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

6061-t6 Aluminum CNC Machining Factory Custom Aluminum Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

ABS+PC Hubcap Wheel Cover 15 Inch for Tesla Model 3

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminium Cnc Machining China Custom Source Factory

$0.30Rated 0 out of 5 - CNC Machining Products

Aluminum Alloy 6063 T5 CNC Machined Parts – Precision Custom

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

Aluminum Alloy Access Control Panel Enclosure (CNC Machined)

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Aluminum Alloy CNC Processing

Aluminum Alloy CNC Processing + Black Oxidation

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Auto Parts Milling Turning Machining CNC Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Auto Parts Processing Service Supplier Precision CNC Machined

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

China Stainless Steel Cnc Machining Factory

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

CNC Lathe Machine Parts for Automotive & Aerospace Parts

$5.00Rated 0 out of 5 - CNC Processing Sample Center

CNC lathe non-standard parts precision machining

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

CNC Machining Of Custom Intelligent Humanoid Robot Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

CNC Machining Online: Your Trusted Partner for Custom Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Cnc Machining Prototype Service Savannah – Your One-Stop Solution

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

CNC Machining Rapid On-Demand Production Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 18 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

ABS Engineering Plastic Precision Parts CNC Machining

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Engineering Plastics CNC Processing

CNC Machining Plastic Parts & Injection Molding Services

$0.03Rated 0 out of 5 - CNC Machining Products

CNC Machining Services: CNC Machined PEEK Plastic Precision Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Engineering Plastics CNC Processing

CNC Machining Services: Custom Chinese Scooter Plastic Body Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

CNC Machining Services: Precision CNC Machined PEI Plastic Components

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

PA Nylon Engineering Plastic Precision CNC Machined Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

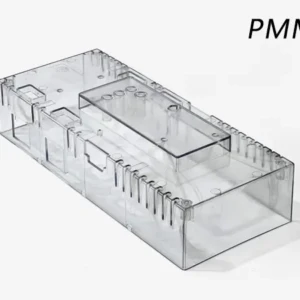

PMMA Acrylic Precision Parts CNC Machining Service

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Precision 5 Axis CNC Milling Of Custom Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Ivc Customer Motorcycle Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Plastic Machining for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

Precision CNC-Machined PP Polypropylene Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Machining Products

PTFE Plastic Precision Parts CNC Machining

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 9 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

ABS+PC Hubcap Wheel Cover 15 Inch for Tesla Model 3

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Ivc Customer Motorcycle Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Plastic Machining for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 8 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Ivc Customer Motorcycle Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Plastic Machining for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 8 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Ivc Customer Motorcycle Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Plastic Machining for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 8 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Ivc Customer Motorcycle Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Plastic Machining for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 8 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Ivc Customer Motorcycle Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Plastic Machining for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 8 results

- ABS CNC Machining

5 Axis CNC Machining Center For Your Project – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Machining Manufacturer – Custom Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

CNC Swiss Precision Machining – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Complex Metal & Plastic Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Machining for Ivc Customer Motorcycle Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Precision CNC Plastic Machining for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Rapid CNC Machining Services for Your Success

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - ABS CNC Machining

Your Precision CNC Machining Partner – From Prototype to Production

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Showing all 22 results

- Auto Parts

Auto Parts Milling Turning Machining CNC Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Auto Parts Processing Service Supplier Precision CNC Machined

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Automotive Engine Oil Pan CNC Machining Services

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

CNC Lathe Machine Parts for Automotive & Aerospace Parts

$5.00Rated 0 out of 5 - Auto Parts

CNC Machining for Electric Motor Stator Rotor

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

CNC Machining Services: Auto Parts Suppliers Harrisburg Pennsylvania

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Custom CNC Machining & Turning – Your CNC Expert for Robotics & Automotive

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Custom CNC Machining Service for Motorcycle Auto Parts

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Custom CNC‑Machined Motorcycle Engine Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Golden Valley Auto Parts And Hardware CNC Machining

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

GreatLight CNC Machining – Precision Engine Hardware Associated Parts

Rated 0 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - CNC Processing Sample Center

Precision Automotive Radiator Aluminum Alloy CNC Machining Services

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99. - Auto Parts

Precision Metal CNC Machining for Automotive & Beyond

Rated 5.00 out of 5$39.99Original price was: $39.99.$19.99Current price is: $19.99.

Understanding Precision Robot Parts and Their Critical Role in Automation

Precision robot parts form the fundamental building blocks of modern automated systems, where micron-level accuracy directly correlates to operational performance and reliability. These CNC machined components enable the complex motion, positioning, and functionality that define today’s industrial and collaborative robotics. At GreatLight, we engineer robotic parts that meet the stringent demands of continuous operation in manufacturing, research, and specialized applications, ensuring your automation investments deliver maximum productivity and longevity.

Critical Robotic Components and Their Applications

Robotic Arm Structural Components

The foundation of any robotic system requires absolute dimensional stability:

Arm segments and linkages with optimized stiffness-to-weight ratios

Custom mounting flanges and adapter plates for motor integration

Base plates and structural frames with precise mounting features

Wrist housings and rotation mechanisms for end-effector mounting

Shoulder and elbow joint housings with bearing seat precision

Drive and Transmission System Components

Power transmission elements where precision ensures efficiency and longevity:

Precision gears and gearboxes for robotic joint actuation

Harmonic drive components with complex tooth profiles

Custom timing pulley and belt drive systems

Lead screws and ball screw assemblies for linear motion

Couplings and shaft connectors with minimal backlash

End-Effector and Tooling Components

The interface between robot and task demands specialized solutions:

Custom gripper jaws and manipulation fingers

Tool changers and quick-disconnect mechanisms

Force-torque sensor mounting plates and adapters

Vacuum cup holders and pneumatic component mounts

Welding torch holders and application-specific fixtures

Material Science for Robotic Applications

Aluminum Alloys for Weight-Sensitive Applications

7075-T6 for high-stress structural components requiring maximum strength

6061-T6 for general structural applications with excellent machinability

2024 for applications demanding good fatigue resistance

Mic-6 cast plate for dimensional stability in large flat components

Steel and Specialty Alloys for Demanding Environments

4140 pre-hardened steel for wear-resistant components

304 and 316 stainless steel for corrosive environments

17-4PH stainless for high-strength corrosion-resistant applications

Titanium Ti-6Al-4V for maximum strength-to-weight ratios

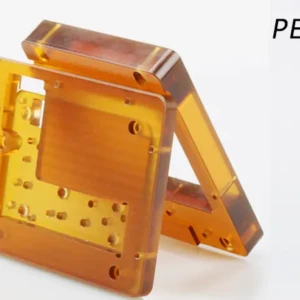

Engineering Plastics and Composites

PEEK for high-temperature and chemically resistant applications

UHMW-PE for low-friction wear surfaces and guides

Delrin (POM) for precision bushings and low-friction components

Garolite for electrical insulation and structural applications

Technical Capabilities for Precision Robot Parts Manufacturing

Advanced Multi-Axis Machining

Our manufacturing capabilities ensure complex robotic components are produced to exact specifications:

5-axis simultaneous machining for complex contours in single setups

High-speed machining maintaining ±0.002mm positional accuracy

Turn-mill centers for complete part processing in one operation

Swiss-type machining for small, precision shaft-type components

Surface Treatment and Finishing

Anodizing (Type II and III) for wear and corrosion resistance

Hard coat anodizing for extreme abrasion resistance

Electroless nickel plating for corrosion protection and hardness

Passivation for stainless steel components

Powder coating for decorative and protective finishes

Quality Assurance for Robotic Component Manufacturing

Comprehensive Metrology and Verification

Zeiss CMM inspection with 1.2µm accuracy for full dimensional validation

Optical comparators for rapid feature verification and profile analysis

Surface roughness measurement for critical bearing and sealing surfaces

Roundness and cylindricity measurement for rotational components

Custom fixture creation for production quality control

Certification and Documentation

ISO 9001:2015 certified quality management system

Material certifications with full traceability

First article inspection reports with complete dimensional data

Statistical process control documentation

RoHS and REACH compliance documentation

Applications Across Robotic Systems

Industrial Robot Components

Articulated robot arms for welding, painting, and material handling

SCARA robot components for high-speed assembly applications

Delta robot parts for pick-and-place operations

Gantry system components for large-scale automation

Custom Cartesian system elements for specialized applications

Collaborative Robot (Cobot) Components

Lightweight structural elements for safe human interaction

Force-torque sensor integration components

Safety-rated plastic covers and protective elements

Joint modules and actuator housings for compact designs

Custom end-effector interfaces for quick tool changing

The Manufacturing Process for Precision Robot Parts

Design for Manufacturing Analysis

CAD model review and optimization for manufacturability

Tolerance analysis and stack-up verification

Material selection guidance based on application requirements

Cost-reduction recommendations without compromising function

Fixture design and process planning

Production Workflow

Raw material certification and verification

Multi-operation machining with in-process verification

Deburring and edge preparation for safety and function

Surface treatment application and verification

Final inspection, packaging, and documentation

Industries Served and Specific Applications

Automotive Manufacturing Automation

Welding robot arm components and tooling

Material handling grippers and end-effectors

Assembly system components and fixtures

Vision system mounts and positioning elements

Electronics and Semiconductor Manufacturing

Cleanroom-compatible robot components

Precision positioning stages and linear motion elements

Wafer handling end-effectors and manipulators

Inspection system components and mounts

Why Partner with GreatLight for Your Robot Parts?

With extensive experience serving the robotics and automation industry, GreatLight brings both manufacturing excellence and practical application knowledge to every project. Our engineers understand the unique demands of robotic systems, from collaborative robots working alongside humans to industrial robots operating in demanding manufacturing environments.

We recognize that robotic components must perform reliably in continuous operation, often in critical production processes. This understanding drives our commitment to quality, precision, and reliability in every component we manufacture. Our clients trust us to deliver parts that not only meet specifications but enhance the performance and reliability of their robotic systems.

Begin Your Robotic Component Project Today

Ready to advance your robotic system with precision-manufactured components? Contact our engineering team today for a comprehensive design review and quotation. Submit your CAD files to [email protected] or visit our website to learn more about our complete robotic component manufacturing capabilities. Let us help you build the future of automation with components engineered for precision, durability, and performance.

Global Trade Data Analysis Report on Robotics Industry

About Company

Processing Capabilities

Our Vision

GreatLight Metal Technology Co., Ltd

Great Light was founded in 2011, Adjacent to Shenzhen, And is located in Chang’an, Dongguan City, The capital of precision processing of hardware molds.

Factory is about 7,600 square meters, With 150 employees, Equipped with large high-precision 5-Axis, 4-Axis, 3-Axis CNC Machining centers, Lathes, Milling machines, Grinders, Spark machines, Vacuum mold machines, SLM 3D Printers, SLA 3D Printers, SLS 3D Printers and other peripheral equipment precision equipment 127 sets, With 3 wholly-owned manufacturing factories, Is a production enterprise specializing in precision processing of rapid prototyping handboard models.

Great Light focuses on the design, processing, customized production and application of precision handboard models, Providing new and old users with precision CNC Processing services (three-axis, four-axis, five-axis processing), CNC Milling services, Die-casting molds/metal die-casting processing services, Vacuum casting customization, Sheet metal processing customization, Stainless steel 3D printing, Aluminum alloy 3D printing, Titanium alloy 3D printing, Mold steel 3D printing and nearly 100 kinds of rapid prototyping processing services and comprehensive solutions. And it is equipped with a one-stop post-surface processing service.

Great Light has many years of experience in precision prototype model processing, With high precision (±0.001mm / 0.001 In and above precision requirements can be processed), After-sales guarantee, Free rework for quality issues.

- Five-Axis CNC

- Four-Axis CNC

- Three-Axis CNC

- Milling & Turning

CNC Technology |

5-Axis Five-Axis CNC |

4-Axis Four-Axis CNC |

3-Axis Three-Axis CNC |

CNC Milling Milling & Turning |

Machining Materials Including But Not Limited To: | Aluminium, Brass, Inconel, Tool Steel, Tool Stee, Titanium, Alloy Steel, Stainless steel, Copper, Low Carbon Steel | Aluminium, Brass, Inconel, Tool Steel, Tool Stee, Titanium, Alloy Steel, Stainless steel, Copper, Low Carbon Steel | Aluminium, Brass, Inconel, Tool Steel, Tool Stee, Titanium, Alloy Steel, Stainless steel, Copper, Low Carbon Steel | Aluminium, Brass, Inconel, Tool Steel, Tool Stee, Titanium, Alloy Steel, Stainless steel, Copper, Low Carbon Steel |

Material Abbreviation | AL / SS / Brass / Steel / TC4 | AL / SS / Brass / Steel / TC4 | AL / SS / Brass / Steel / TC4 | AL / SS / Brass / Steel / TC4 |

Specification | Various sizes and thicknesses of plates and round bars | Various sizes and thicknesses of plates and round bars | Various sizes and thicknesses of plates and round bars | Various sizes and thicknesses of plates and round bars |

Common Post-processing | Oil spraying, powder spraying, passivation, oxidation, blackening, electrophoresis, silk screen printing, laser engraving, polishing | Oil spraying, powder spraying, passivation, oxidation, blackening, electrophoresis, silk screen printing, laser engraving, polishing | Oil spraying, powder spraying, passivation, oxidation, blackening, electrophoresis, silk screen printing, laser engraving, polishing | Oil spraying, powder spraying, passivation, oxidation, blackening, electrophoresis, silk screen printing, laser engraving, polishing |

Tolerance Range | ±0.001mm / 0.001 In and above precision requirements can be processed | ±0.001mm / 0.001 In and above precision requirements can be processed | ±0.001mm / 0.001 In and above precision requirements can be processed | ±0.001mm / 0.001 In and above precision requirements can be processed |

Advantage | Multi-faceted structural products can be formed in one go with high precision | High efficiency, re-cutting capability, simple operation, high precision, and good surface effect | High efficiency, re-cutting capability, simple operation, high precision, and good surface effect | High precision, good surface finish, and high efficiency |

Shortcoming | The size of the processed products is limited, the processing speed is slow, and the cutting is light | |||

Main Fields | Prototype, automobile, medical, digital electronics, toys, mechanical equipment, aerospace, etc. | Prototype, automobile, medical, digital electronics, toys, mechanical equipment, aerospace, etc. | Prototype, automobile, medical, digital electronics, toys, mechanical equipment, aerospace, etc. | Prototype, automobile, medical, digital electronics, toys, mechanical equipment, aerospace, etc. |

Maximum Processing Size Of The Equipment | 4000*400*150mm 750x1150x550mm 600*600*600mm 500*500*450mm 500*310*200mm 1575*157*60In 295x452x216In 236*236*236In 200*200*177In 200*122*78.7In | 1500*800*300mm 800*500*400mm 600*400*300mm 590*315*118In 315*200*157In 236*157*118In | 1500*800*300mm 800*500*400mm 600*400*300mm 590*315*118In 315*200*157In 236*157*118In | Diameter 500mm / 200 In |

Processing Capabilities | 16 Units | 12 Units | 27 Units | 16 Units |

Standard Lead Time | 3 Business Days | 3 Business Days | 3 Business Days | 3 Business Days |

| Starting Price: $11/H | Starting Price: $11/H | Starting Price: $9/H | Starting Price: $9/H |

Precision Forged by Light, Excellence Driven by Innovation

Great Light Technology continues to pioneer CNC industry advancements, empowering high-end manufacturing, smart industries, and global supply chains, leading the intelligent manufacturing revolution!

Rapid Prototyping Services

CNC Grinding

CNC Turning

99%

Product Pass Rate

Testimonials

See What Our Happy Customers Say

- List Item #1

- List Item #1

- List Item #1

- List Item #1

- List Item #1

Solved our harmonic drive backlash! GreatLight’s 0.001″ concentricity on 7075-T6 joints boosted positioning repeatability 5x. 5 revisions in 2 weeks – insane agility!

Alison Burgas

- List Item #1

- List Item #1

- List Item #1

- List Item #1

- List Item #1

Slashed EV battery housing costs by 33%! Their 5-axis CNC achieved perfect cooling channel alignment (±0.03mm) we couldn’t get elsewhere. On-time delivery for 10k units!

Mark Adam

- List Item #1

- List Item #1

- List Item #1

- List Item #1

- List Item #1

From CAD to flight-ready titanium arms in 5 days! 0.05g imbalance allowed 40min extra flight time. Scrapped 3 ‘experts’ before finding these wizards. Game-changer!

Lio Hernandez

SGS Certification

ISO Standards

Environmental Compliance

Customer Satisfaction

Continuous Improvement

Product Ordering FAQs

A1: We are a professional manufacturer with very good production experience. We can accept OEM, ODM according to your needs, and guarantee competitive price and quality.

A2: Yes, we can provide free samples for stock, you only need to pay the shipping cost. Customized goods require a partial deposit, which can be deducted in the order.

A3: We are ISO9001 certified factory, and have a professional QC team to check every item from production to packaging.

A4: Generally 2-5 days after payment for stock products, and 10-15 days after payment for customized goods.

A5: Generally, new customers pay T/T50% as deposit, and 50% balance before delivery. The specific situation can be negotiated, and old customers can set a credit limit.