Mastering Build Orientation: The Key to High-Quality 3D Prints

Imagine spending hours designing a perfect 3D model only to have it warp, split, or fail mid-print. Often, the culprit isn’t your design or printer—it’s improper build orientation. This fundamental yet frequently overlooked aspect of 3D printing significantly impacts structural integrity, surface quality, and manufacturing efficiency. Let’s explore how strategic part orientation transforms printing outcomes.

Why Build Orientation Matters

Build orientation refers to how your 3D model is positioned relative to the print bed during fabrication. This seemingly simple decision cascades through every aspect of a print:

- Structural strength along layer lines

- Surface finish quality

- Support material requirements

- Print time and material usage

- Dimensional accuracy of critical features

Neglecting orientation optimization often leads to failed prints, wasted resources, and frustration.

Core Principles of Build Orientation Strategy

1. Maximizing Bed Adhesion and Stability

Flat, Broad Surfaces = Foundation Security

Prioritize orientations that maximize contact with the build plate. Larger contact areas improve bed adhesion and prevent warping. Avoid orientations requiring rafts or brims unless unavoidable, as these add post-processing work. Always ask: "Which surface provides the most stable foundation?"

2. Aligning with Mechanical Stress Directions

Layer Line Vulnerability

Printed parts exhibit anisotropic strength—weaker along the Z-axis where layers bond. Orient parts so the primary stress direction runs perpendicular to layer lines. For load-bearing components, position the highest stress vectors parallel to the XY plane to leverage maximum material strength.

3. Respecting Printer Volume Constraints

Reality-Check Your Build Space

Before optimizing for other factors, verify the part fits your printer in the chosen orientation. Tall vertical orientations might exceed Z-axis limits. For batch printing, rotate parts to maximize platform utilization—sometimes a 45-degree angle yields higher density packing.

4. Strategic Reduction of Support Structures

The Support Minimization Calculus

Supports increase material costs, extend print times, and leave surface imperfections. Follow these tactics:

- Orient to keep overhangs under 45° whenever possible

- Position complex geometries toward the build plate

- Isolate high-detail surfaces away from support contact

Pro Tip: Use tree supports in slicers for difficult geometries—they’re easier to remove and waste less material.

5. Preserving Dimensional Accuracy

Critical Features First

Identify toleranced features (holes, mating surfaces) and orient them optimally:

- Holes: Print vertically for perfect circularity

- Flat Surfaces: Orient parallel to XY plane to avoid "stair-stepping"

- Fine Details: Position away from support contact zones

6. Balancing Print Time and Post-Processing

Time vs. Finish Tradeoffs

Shorter print orientations often come with compromises:

- Fast prints may require more supports

- Support-free orientations might extend Z-height and increase time

Calculate the removal and finishing effort into your decision—a 30-minute time saving isn’t worth hours of sanding.

Real-World Orientation Case Studies

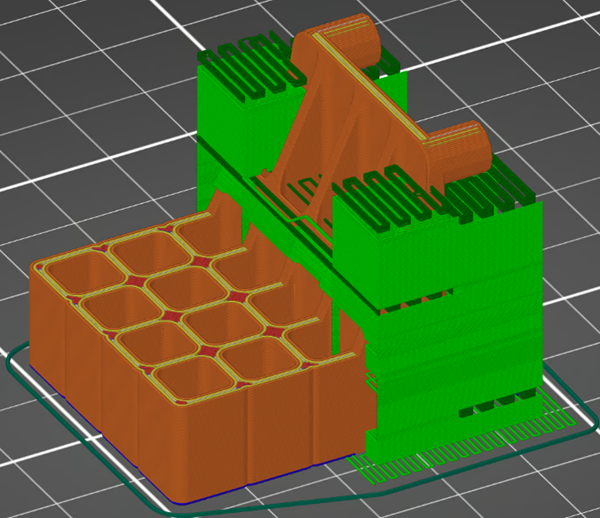

Case 1: The Horizontal Workholder (Optimal)

Dimensional precision achieved through vertical hole orientation (Source: Mark Vanhorne, All3DP)

Configuration:

Part printed flat with maximum bed contact

Performance Analysis:

- ✅ Bed Adhesion: Excellent (large surface area)

- ✅ Strength: Stress perpendicular to Z-axis

- ⏱️ Time: 268 min (only 19 min supports)

- 🏗️ Supports: Minimal—confined to tool-holes

- 🔧 Post-Processing: Easy removal with smooth functional surfaces

- 🎯 Critical Features: Holes printed vertically for precision

Verdict: Ideal for functional parts requiring precision and strength.

Case 2: Y-Axis Rotation (Time-Saver)

Reduced Z-height minimizes print time (Source: Mark Vanhorne, All3DP)

Configuration:

90° rotation around Y-axis

Performance Analysis:

- ✅ Time: Fastest (226 min total)

- ❗ Supports: 57 min—cover tool holes and pins

- ⚠️ Surface Finish: Supports leave marks on functional areas

- 📏 Precision: Horizontal holes less dimensionally accurate

- 🤔 Tradeoff: Time saved now costs extra finishing later

Best For: Non-critical prototypes needing rapid iteration.

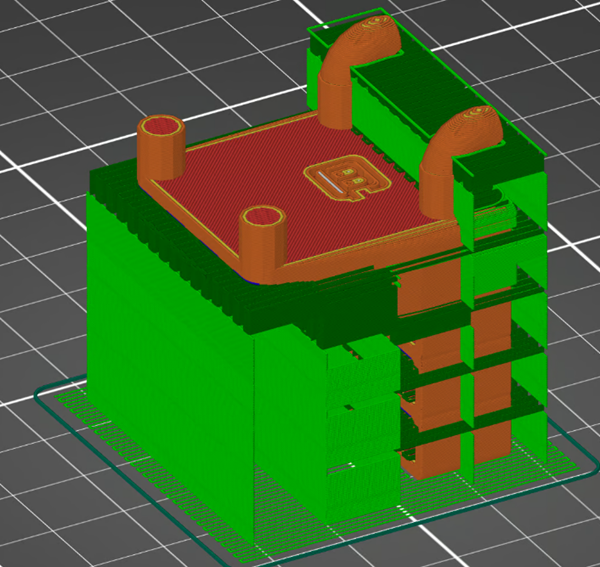

Case 3: X-Axis Rotation (Structural Risk)

Significant support requirement increases post-processing (Source: Mark Vanhorne, All3DP)

Configuration:

90° rotation around X-axis

Performance Analysis:

- ⚠️ Adhesion: Small contact area requires substantial supports

- 🚫 Strength: Critical stress parallel to Z-axis (weakest plane)

- ⏱️ Time: 250 min (62 min supports)

- 🔨 Post-Processing: Extensive support removal and finishing

- ⚙️ Precision: Pins accurate but holes compromised

Use Case: Avoid unless specific feature alignment demands it.

Advanced Orientation Tactics

- Adaptive Angles: For complex geometries, use 15-30° angles to reduce supports while maintaining strength

- Feature Splitting: Cut models into sub-components for optimal individual orientation

- Variable Layer Heights: Combine thicker layers for solid sections with fine layers for critical details

- Thermal Simulation: For industrial applications, simulate thermal stresses in different orientations

Orientation Optimization Workflow

- Identify Critical Features: What must be dimensionally perfect?

- Determine Stress Vectors: How will the part be loaded?

- Test Virtual Placements: Use slicer previews to compare alternatives

- Calculate Cost/Benefit: Weigh time, supports, and finishing needs

- Prototype Key Options: Print critical portions to validate

The Future of Orientation Optimization

Emerging solutions are automating orientation decisions:

- AI-Driven Slicers: Machine learning algorithms predicting optimal placement

- Topology-Aware Systems: Software considering internal stress distributions

- Multi-Axis Printers: Machines that dynamically reorient parts during printing

Strategic orientation comparison (Source: Mark Vanhorne, All3DP)

Conclusion: Precision Through Positioning

Build orientation is the silent architect of successful 3D printing. As demonstrated in our case studies, optimal orientation (like Case 1) consistently delivers superior mechanical properties, surface quality, and efficiency.

Key takeaways for your next project:

- Always prioritize functional requirements over convenience

- Treat orientation as a design parameter—not just a slicing step

- When in doubt, default to orientations maximizing bed contact

- For mission-critical parts, prototype multiple orientations

Remember: The best orientation reduces failures while minimizing secondary operations. Master this variable, and you unlock dramatically improved 3D printing economics and part performance.