Reverse engineering, also known as reverse modeling, is a method of analyzing a finished product to understand its design and manufacturing. By deciphering the structure and composition of an object, this technology offers the possibility of reproducing it, improving it or drawing inspiration from it for new creations. While this also applies to software and other technical fields, here we will focus on its application in mechanical engineering.

AndCombined with 3D printing, reverse engineering becomes a powerful tool transforming many industries. This combination enables recreation, optimization and innovation around components with unprecedented ease and precision. As 3D scanning and additive manufacturing technologies continue to advance, this combination paves the way for more efficient, practical and sustainable solutions. Let’s see how this technological synergy works, its applications and its advantages.

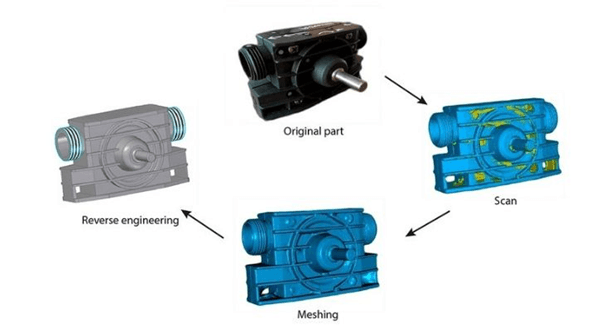

Reverse engineering process (photo credit:3dcapura.cz)

Reverse engineering: a multi-step approach

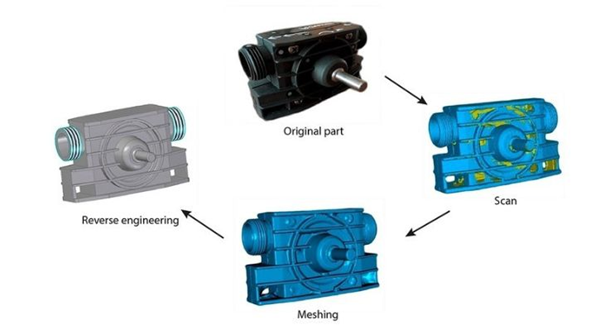

Reverse engineering begins with scanning physical objects. Laser scanning, computed tomography (Technologies such as scanners or photogrammetry capture the details of objects in the form of point clouds. This data is then used in 3D modeling software to generate CAD (computer-aided design) models.

This digital model can then be analyzed, modified and optimized before being used to produce new parts. existIn 3D printing, CAD files are sent to a 3D printer to create the object with impressive precision.

3D scanning simplifies reverse engineering (Photo credit: Artec3D)

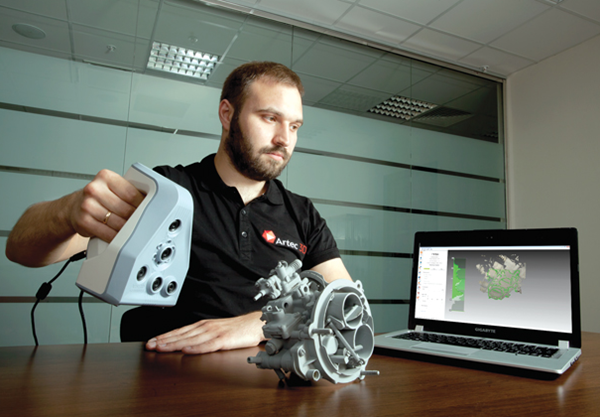

Software dedicated to reverse engineering

Software proficiency plays a key role in this process. Specific tools can not only reconstruct missing parts of damaged parts, but also automatically model complex designs and analyze object dimensions and surfaces. The most commonly used software includes:Geomagic Design X, Catia, Creo, Mesh2Surface, Artec Studio Fusion 360.

Why choose reverse engineering?

The advantages of reverse engineering are numerous, particularly for manufacturers:

1、Product development:It allows you to customize or improve existing parts to create more efficient products.

2、optimization:Parts can become lighter, stronger or more durable, helping to reduce production costs.

3、Copy not found of the part:In the absence of technical plans or spare parts on the market, reverse engineering is often the only solution.

4、Innovation:Analysis of existing products often inspires the creation of new solutions.

5、Digital twin:Accurate digital models for predictive maintenance or simulation rely on reverse engineering.

CAD software is used to design reverse-engineered parts (Photo credit: Autodesk)

The role of 3D printing in reverse engineering

by addingAdd 3D printing to reverse engineering and the possibilities expand dramatically. The design freedom offered by additive manufacturing makes it possible to recreate complex shapes or unusual geometries that would be impossible or too expensive to produce.

Benefits of 3D printing

1、faithful reproduction: Ideal for small parts with fine details.

2、Repair damaged parts: An economical and quick alternative to traditional methods.

3、Adaptability:Whether polymers or metals, stereolithographyTechnologies such as (SLA) or laser powder bed fusion (L-PBF) are particularly suited to the needs.

3D printing combined with reverse engineering is often used to reproduce damaged parts that are no longer commercially available (Photo credit: Formlabs)

Specific application: when theory becomes practice

1、car:Classic vehicle restoration benefits greatly from this combination of techniques. It allows you to recreate rare pieces while respecting the integrity of the original model.

2、Aerospace: Weight reduction and optimized component performance improve aircraft safety and efficiency.

3、Architecture and Art:The reconstruction of damaged parts of historical monuments or the reproduction of works of art to make them accessible are striking examples of the impact of these technologies in the cultural field.

Reverse engineering of automotive parts contributes to the maintenance and optimization of older vehicles. (Photo credit: Mihailo·Marisic)

Towards a new era of manufacturing and design

passReverse engineering enhanced by 3D printing redefines traditional methods of design and manufacturing. This combination of technologies not only leads to innovative solutions, but also vital flexibility and speed in a world where personalization and efficiency are priorities.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.