Introduction to Metal 3D Printing Optimization

The University of Toronto’s engineering school, under the leadership of Professor Zou Yu, has been exploring the application of machine learning (ML) to enhance the 3D printing process, particularly in the realm of metallic 3D printing. This technology has far-reaching implications for various industries, including automotive, aerospace, and nuclear energy. Machine learning, a subset of artificial intelligence, involves the use of algorithms to analyze complex data, identify patterns, and make predictions. In a recent publication in the journal Additive Manufacturing, researchers introduced an innovative framework designed to improve the accuracy and reliability of products produced through 3D printing.

The Challenge of 3D Metal Printing

Metal 3D printing, also known as additive manufacturing, faces a significant challenge in process optimization. The goal is to ensure product quality and enhance production efficiency, but finding the optimal parameters among numerous options is a daunting task. Despite advancements in simulation techniques, optimization often relies on time-consuming trial-and-error approaches that may not adapt well to the diversity of materials and shapes, and struggle to achieve multiple objectives simultaneously.

The Role of Directed Energy Deposition (DED)

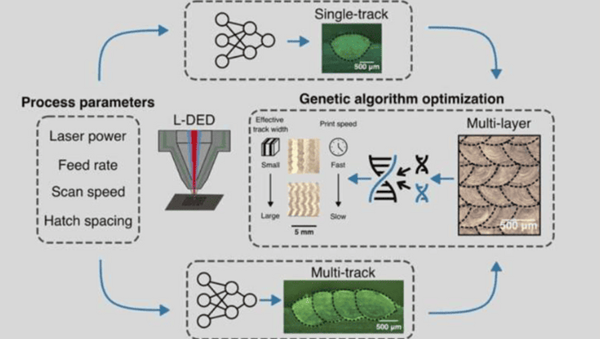

Directed Energy Deposition (DED) is a technology used in metal 3D printing that is limited by the high cost required to find correct process parameters through repeated trials and errors. According to Xiao Shang, a doctoral student and lead author of the study, "Our approach allows us to quickly determine the best process parameters for different applications according to specific industry requirements." This highlights the need for an efficient method to determine optimal parameters for various materials and components, each with unique characteristics requiring precise settings, speeds, and temperatures.

The Innovative Framework: Helped

The researchers’ new approach, termed "Helped," utilizes a closed-loop system. Initially, a genetic algorithm inspired by natural selection proposes combinations of parameters. An ML model then evaluates these choices to verify their efficiency in print quality. The genetic algorithm tests the validity of these suggestions by repeating the process until the best-adjusted parameters are found. This method significantly reduces the time required to determine optimal process parameters, with the potential to predict geometry within an hour.

Combining Additive Manufacturing and Artificial Intelligence

The development of this method involved conducting a large number of experiments to collect data. By integrating additive manufacturing with artificial intelligence, the researchers aim to create an autonomous laser system capable of adjusting parameters in real-time to ensure production quality, compatible with different materials and shapes. This integration has the potential to revolutionize the field of metal 3D printing by enhancing the efficiency, accuracy, and adaptability of the process.

The Significance of Machine Learning in 3D Printing

Machine learning plays a crucial role in the optimization of 3D metal printing. By analyzing complex data and identifying patterns, ML algorithms can predict the optimal process parameters for different materials and applications. This capability reduces the reliance on trial-and-error methods, saving time and resources. Furthermore, the use of ML in 3D printing can lead to the development of more complex and customized products, expanding the potential applications of this technology.

Future Directions

The future of metal 3D printing optimization lies in the continued development and refinement of ML algorithms and their integration with additive manufacturing technologies. As the field advances, we can expect to see more efficient, adaptable, and autonomous systems capable of producing high-quality products with precision and speed. The collaboration between researchers and industry professionals will be crucial in translating these advancements into practical applications, driving innovation in various sectors.

Conclusion

The application of machine learning to optimize the 3D metal printing process represents a significant step forward in the field of additive manufacturing. By addressing the challenges associated with process optimization, researchers have paved the way for more efficient, reliable, and adaptable production methods. As this technology continues to evolve, it is likely to have a profound impact on industries reliant on metal 3D printing, enabling the creation of complex products with unprecedented precision and speed. The future of metal 3D printing is undoubtedly linked to the development of more sophisticated ML algorithms and their integration with manufacturing technologies, promising a new era of innovation and advancement.

References

- Additive Manufacturing journal publication on the "Helped" framework.

- University of Toronto’s engineering school research on the application of ML in metal 3D printing.

- Industry reports on the impact of ML on additive manufacturing and 3D printing technologies.

Key Terms

- Machine Learning (ML): A subset of artificial intelligence that involves the use of algorithms to analyze data, identify patterns, and make predictions.

- Additive Manufacturing: The process of creating products by adding materials layer by layer, commonly known as 3D printing.

- Directed Energy Deposition (DED): A technology used in metal 3D printing that involves the deposition of material by focusing a directed energy source.

- Genetic Algorithm: A search heuristic that is inspired by Charles Darwin’s theory of natural evolution. This algorithm reflects the process of natural selection where the fittest individuals are selected for reproduction in order to produce the offspring of the next generation.