Micro 3D printing is revolutionizing the landscape of manufacturing and design, offering unparalleled precision and the ability to create intricate structures at a micro scale. This guide will delve deep into the technology, applications, benefits, challenges, and future trends of micro 3D printing.

## What is Micro 3D Printing?

Micro 3D printing, as the name suggests, is the process of creating three-dimensional objects by layering material in incredibly fine resolutions—often at the scale of micrometers. It utilizes techniques such as laser-based microfabrication, two-photon polymerization, and inkjet printing, enabling the production of highly detailed and complex designs that cannot be achieved with traditional manufacturing processes.

Micro 3D printing leverages advanced materials including photo-resins, metals, and polymers, allowing for a level of customization that meets the demands of various industries—from medical devices to electronics.

## The Technology Behind Micro 3D Printing

### 1. Two-Photon Polymerization

Two-photon polymerization (TPP) is a cutting-edge technique widely used in micro 3D printing. It relies on a two-photon absorption event, whereby two photons of a laser beam are absorbed simultaneously by a photosensitive material, causing it to polymerize and harden. This process allows for exceptionally fine features, which can reach sub-micrometer resolutions.

### 2. Laser-Based Fabrication

Laser-based fabrication employs focused laser beams to selectively cure or melt materials. Techniques like Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) are pivotal in producing micro-scale components by sintering or melting powder materials layer by layer.

### 3. Inkjet Printing

Inkjet technology has evolved to cater to micro 3D printing by using ultra-fine nozzles to deposit tiny droplets of ink-like materials, which can include conductive metals and polymers. When combined with heat or UV light, these droplets can form solid structures with intricate designs.

## Applications of Micro 3D Printing

Micro 3D printing is increasingly being employed across various sectors due to its ability to offer customized solutions. Here are some prominent applications:

### 1. Medical Devices

In the medical field, micro 3D printing is paving the way for the development of advanced devices such as micro needles, scaffolds for tissue engineering, and personalized implants. The ability to create porous structures can significantly enhance drug delivery systems and tissue regeneration.

### 2. Electronics

The electronics industry harnesses micro 3D printing to produce compact and lightweight components. This technology allows for the creation of intricate circuit designs, heat sinks, and micro-sensors that enhance the functionality of gadgets while minimizing size.

### 3. Aerospace

In aerospace, weight distribution and material integrity are critical. Micro 3D printing enables the fabrication of lightweight structures and components with complex geometries, improving fuel efficiency and performance in flights.

### 4. Art and Design

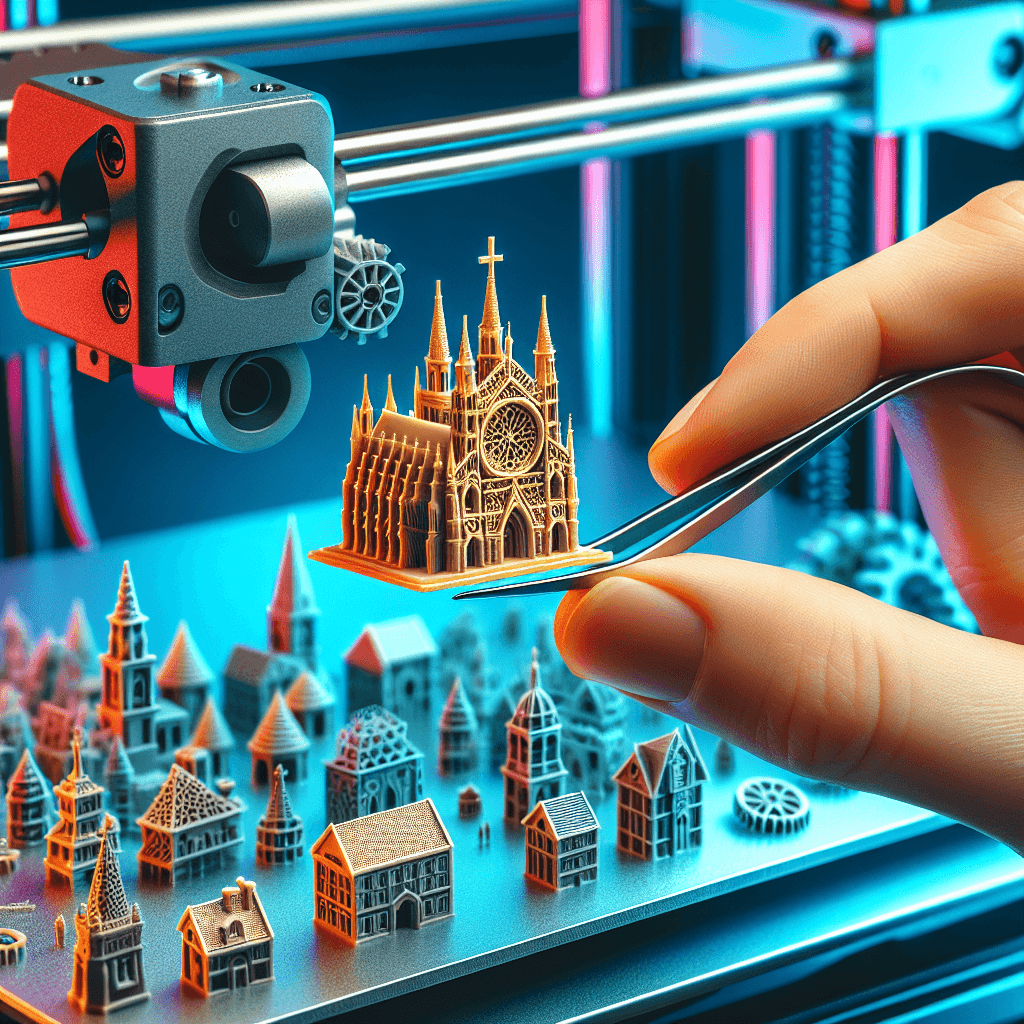

Micro 3D printing opens new avenues for artists and designers, allowing for the creation of fine art pieces, jewelry, and intricate patterns that were previously impossible to achieve. This capability helps artists push the boundaries of creativity.

## Benefits of Micro 3D Printing

### 1. Precision and Detail

Micro 3D printing offers a level of detail and precision that traditional manufacturing methods struggle to match. The ability to create complex geometries and intricate designs allows designers and engineers to develop innovative solutions.

### 2. Material Efficiency

Because micro 3D printing uses additive manufacturing techniques, it minimizes waste. Materials are added only where needed, reducing excess material compared to subtractive manufacturing.

### 3. Customization

With micro 3D printing, mass customization becomes a realistic proposition. This technology allows for the production of tailored solutions that meet specific requirements, facilitating innovation across industries.

### 4. Rapid Prototyping

Micro 3D printing allows for faster prototyping cycles, enabling designers to quickly iterate on their designs and bring products to market sooner. This rapid development can lead to significant cost savings.

## Challenges of Micro 3D Printing

Despite its numerous benefits, micro 3D printing faces several challenges that must be addressed for widespread adoption.

### 1. Equipment Cost

The high cost of micro 3D printing equipment can be a barrier to entry for many businesses, particularly startups. While prices are coming down, investing in high-resolution printers requires significant capital.

### 2. Material Limitations

While there are many materials available for micro 3D printing, the options are still limited compared to traditional manufacturing. This can restrict the types of designs that can be produced, particularly in industries that require specific material properties.

### 3. Technical Complexity

Micro 3D printing technology is complex and requires specialized knowledge and training. Companies may need to invest in employee training, which can increase overall costs.

## Future Trends in Micro 3D Printing

As technology continues to advance, several trends are expected to shape the future of micro 3D printing.

### 1. Expansion of Materials

The development of new materials tailored for micro 3D printing will likely continue, broadening the scope of applications. Innovations in biocompatible materials can lead to advancements in medical device production.

### 2. Integration with AI and Automation

Integrating artificial intelligence with micro 3D printing can lead to smarter manufacturing processes. AI can optimize designs and automate processes, making production faster and more efficient.

### 3. Sustainability Practices

As sustainability becomes increasingly important in manufacturing, micro 3D printing can play a role in reducing waste and utilizing recycled materials. Companies will likely explore greener practices to cater to eco-conscious consumers.

### 4. Enhanced Resolution and Speed

With ongoing advancements in laser technology and material science, the resolution and speed of micro 3D printing processes will likely improve. This will enable faster production of intricate designs, making the technology more widely applicable.

## Conclusion

Micro 3D printing is a burgeoning field with the potential to reshape various industries through its exceptional precision, material efficiency, and customization capabilities. By addressing its inherent challenges and embracing emerging trends, businesses can unlock new opportunities and drive innovative solutions in design and manufacturing.

As micro 3D printing technology continues to evolve, its impact on the world will only grow, marking a new era of creativity and production in an ever-changing marketplace. Whether in medicine, electronics, aerospace, or art, the future looks bright for this transformative technology, bringing dreams and designs to life with unmatched detail and accuracy.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.