Ultimate Guide to 3D Printing Troubleshooting: Mastering FDM & SLA Techniques

Why Troubleshooting is Critical in Additive Manufacturing

3D printing failures like warped prints, layer separation, and adhesion issues plague both hobbyists and professionals. At Mohou Research Institute, we’ve compiled comprehensive diagnostics for FDM (Fused Deposition Modeling) and SLA (Stereolithography) technologies based on extensive technical analysis. This guide addresses over 20 common failures with scientifically validated solutions, empowering you to transform frustration into flawless prints.

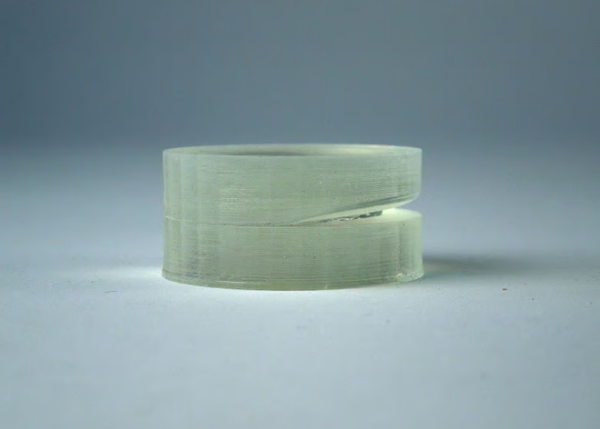

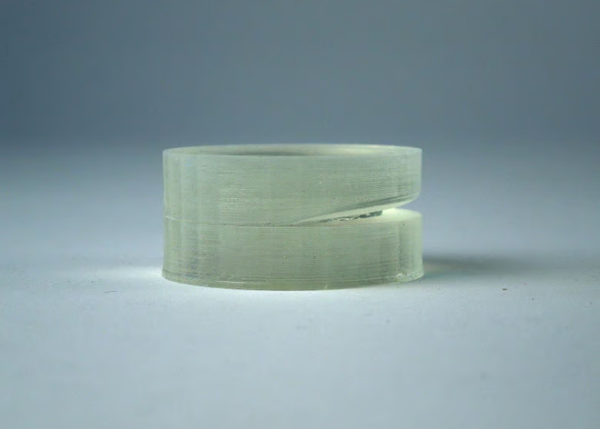

SLA 3D Printing Troubleshooting: Overcoming Resin-Based Challenges

Problem 1: Layer Delamination in SLA Prints

Observed Defect: Visible horizontal cracks between cured resin layers.

Technical Analysis:

- Unsupported Overhangs: Angles >45° without supports detach during peel forces.

- Resin Contamination: Particulates from previous prints scatter UV light.

- Cleaning Damage: Overexposure to isopropyl alcohol (IPA) weakens interlayer bonds.

- VAT Ghosting: Residual cured resin on FEP/film obstructs laser paths.

Engineering Solutions:

- Support Optimization:

- Orient models to minimize overhangs (≤15° ideal)

- Use heavy supports on critical overhangs with 1.2mm contact diameter

- Resin Management:

- Filter resin through 50μm mesh before printing

- Stir resin ≥2 minutes to prevent pigment sedimentation

- VAT Maintenance:

- Inspect FEP film after every print; replace at 0.3mm haze threshold

- Remove "ghost" residues with plastic spatula (never metal)

- Post-Processing:

- Limit IPA bath to <5 minutes at 20°C

- Use ultrasonic cleaners for delicate geometries

Problem 2: Surface Granularity/Artifacting

Root Causes:

- UV light obstruction (dust on galvos/lenses)

- Partially cured resin fragments in vat

- Incorrect layer exposure parameters

Precision Correction Protocol:

- Optical System Calibration:

- Clean laser/galvanometer lenses weekly with anhydrous ethanol

- Perform beam alignment checks using calibration grids

Exposure Tuning: Standard Resin Tough Resin Castable Resin Base Layers 35s 45s 30s Normal Layers 8s 12s 6s - Resin Filtration:

- Use dual-stage filtering: 100μm → 50μm sequential filtration

Problem 3: Feature Loss in High-Resolution Prints

Failure Mechanisms:

- Underexposure: Insufficient polymerization of fine features (<0.2mm)

- Overexposure: Light bleed obscures details (e.g., text engravings)

- Mechanical Stress: Support removal damages delicate elements

Detail Preservation Techniques:

- Exposure Validation:

- Print AmeraLabs Town calibration model

- Adjust exposure in ±0.3s increments based on pin retention

- Anti-Aliasing Enhancement:

- Enable 8x AA in slicing software (reduces pixelation artifacts)

- Support Detachment Protocol:

- Heat supports to 40°C with heat gun before removal

- Use micro-cutter tools for sub-mm features

FDM 3D Printing Troubleshooting: Filament Process Optimization

Problem 1: Thermal Warping & Bed Adhesion

Material Science Perspective:

Thermoplastics experience differential cooling stress at rates of 50-100°C/minute. PLA shrinks 0.2-0.3% while ABS contracts 0.6-0.8% during phase change.

Proven Countermeasures:

- Thermal Management:

- Bed temperature optimization:

- PLA: 55-60°C with PVP glue

- ABS: 100-110°C in enclosed chamber

- Initial layer cooling disabled

- Bed temperature optimization:

Adhesion Engineering: Surface Type Best For Adhesion Promoter PEI Sheet PLA, PETG Isopropyl cleaning Garolite Nylon, PC Magigoo MX-Pro Glass ASA, ABS ABS slurry (15% solution)

Problem 2: Extrusion Anomalies

Diagnostic Flowchart:

mermaid

graph TD

A[Under-Extrusion?] –> B{Nozzle Temp}

B –>|Too Low| C[Increase 5-15°C]

B –>|Correct| D{Clog}

D –>|Partial| E[Cold Pull]

D –>|Complete| F[Nozzle Replacement]

A –> G[Over-Extrusion?]

G –> H{Flow Rate}

H –>|>100%| I[Calibrate E-Steps]

H –>|Correct| J[Reduce Temp 5°C]

Calibration Protocol:

- E-Step Calibration:

- Mark filament 120mm from extruder

- Extrude 100mm at 5mm/s

- Measure residual: ESteps_new = (100 × ESteps_old) / distance_moved

- Flow Rate Calibration:

- Print 20mm cube with 100% infill

- Measure wall thickness

- Flow % = (Target thickness / Actual thickness) × 100

Problem 3: Dimensional Accuracy Issues

Solutions for Common Defects:

- Ghosting/Ringing:

- Reduce jerk to 8mm/s³

- Enable input shaping with 3500Hz accelerometers

- Layer Shifting:

- Check belt tension (≈90Hz twang frequency)

- Verify stepper current (1.2A for NEMA17)

- Stringing:

- Retraction tuning:

- Bowden: 6mm @ 45mm/s

- Direct Drive: 1.5mm @ 25mm/s

- Enable coasting (0.08mm³ volume)

- Retraction tuning:

Unified Process Optimization Framework

Leading 3D printer manufacturers utilize statistical process control (SPC) for error prevention:

Pre-Print Verification:

- Slice validation with G-code analyzers (e.g., PrusaSlicer)

- Thermal imaging of first layer adhesion

In-Process Monitoring:

- Vibration sensors detecting axis resonance

- AI-based webcam systems identifying layer anomalies

- Post-Print Analytics:

- CMM measurement of critical features

- CT scanning for internal defects (industrial SLA)

Research indicates up to 71% defect reduction when implementing this framework with Taguchi method optimization.

Path to Mastery: Building Your Troubleshooting Toolkit

Achieving print perfection requires three pillars:

Preventive Maintenance Schedule:

- FDM: Bi-weekly lubrication; Hotend rebuilds @ 500hrs

- SLA: FEP replacement @ 50 prints; Laser calibration monthly

Material-Specific Profiles:

- Create databases for each filament/resin including:

- Optimal temperature envelopes

- Layer cure/exposure parameters

- Post-processing requirements

- Create databases for each filament/resin including:

- Quantitative Validation:

- Print benchmark models monthly

- Track dimensional tolerances per ISO 2768

As R&D Engineer Marie Keller notes: "The difference between failed artifacts and functional parts lies in systematic diagnostics – treat every print as a data collection opportunity."

Our team continually updates this living guide. Submit your unique failure cases to Mohou Labs for inclusion in our industry-leading knowledge base. Combine these protocols with iterative experimentation to master the science of 3D printing.

Fig: Integrated FDM/SLA diagnostic framework – Analyze failures across thermal, mechanical and material domains

Further Resources:

- ASTM F3187-16: Standard Guide for Directed Energy Deposition

- ISO/ASTM 52900:2021 Additive Manufacturing Fundamentals

OSTI.GOV Technical Reports on Polymer Curing Dynamics