exist3D printingIn this area, choosing the correct file format is a key step in ensuring printing quality and efficiency. With so many formats available, it can be difficult to know which one is best for your project. In this article,magic monkey networkwill be with everyoneDiscussThe most used file formats in 3D printing: STL, OBJ, AMF, 3MF and STEP, detailing their advantages and disadvantages to help you make an informed choice.

STL: essential, but limited

The STL format is short for “stereolithography” and is undoubtedly the most well-known format in the field of 3D printing. This format dates back to 1987 and has become a standard due to its simplicity and universal compatibility. STL works by dividing the model surface into triangles, a process called tessellation. This makes the format very convenient for most CAD software and slicers.

However, this simplicity comes at a price.STL is not suitable for complex geometries, including curves and holes, which may appear as visible polygons when printed. Additionally, not specifying units of measurement can cause scaling issues when preparing a model for printing. Finally, STL files are often prone to errors such as internal intersections and non-collecting edges, which can affect print quality if these issues are not corrected first.

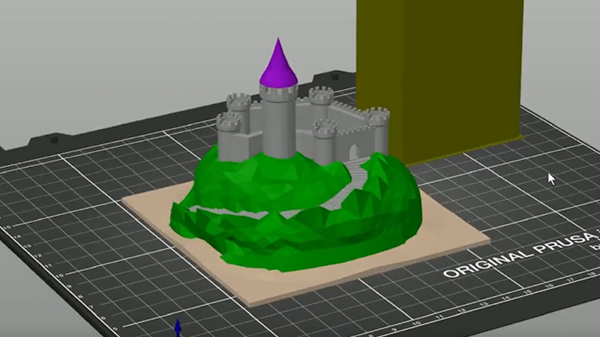

picture1:byThe same 3D model exported by STL or 3MF will not take up as much storage space (Photo credit: Prusa)

When to use it?

For simple projects requiring compatibility with various software,STL remains the first choice. Particularly suitable for beginners or printing without complex geometric requirements.

OBJ: A versatile alternative

The OBJ format, while less popular than STL, offers additional features that can be useful for more complex projects. OBJ was originally developed for 3D animation and allows the storage of additional information such as textures, materials and colors. This makes it particularly suitable for models that require more visual detail.

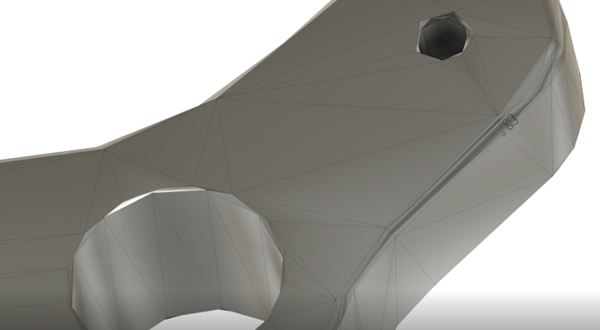

picture2:The OBJ format allows multiple colors to be specified in a single file (Photo credit: Prusa)

One of the main advantages of OBJ is its ability to handle more complex geometries, using not only triangles but also polygons and quadrilaterals. However, such rich features result in larger files and often require additional files to handle materials and textures, which can complicate the printing process.

When to use it?

The OBJ format is ideal for projects where visual details such as texture and color are important. It is also suitable for models with complex geometries that the STL format does not handle well.

picture3:AndUnlike the visual defects that may exist in STL files, the OBJ format generally has higher quality.

AMF: the forgotten format

The AMF (i.e. Additive Manufacturing File) format is a modern evolution of the STL format, designed to overcome its limitations. Launched in 2011, AMF can store complex information such as color, material and lattice structure in a single file while providing greater accuracy using curved triangle tessellation.

Despite its advantages,MFA is not yet widely accepted in the industry. Its lack of compatibility with some older software limits its adoption.

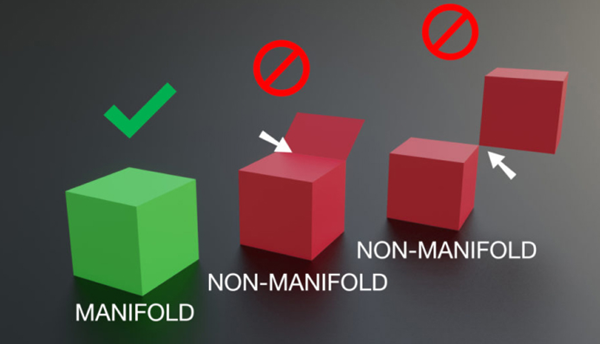

picture4:The modeling isA crucial step in 3D printing, choosing a good file format to export your model is also important during the additive manufacturing process.

When to use it?

If you are working on a project that requires precise and varied information (materials, colors) and your software supports it, thenMFA may be a good choice.

3MF: New standards being developed

The 3MF format was developed in 2015 by a consortium of large companies and aims to become the new standard for 3D printing. Similar in functionality to AMF, 3MF is aiming for greater acceptance and is already supported by a growing number of software and hardware products.

picture5:The 3MF format helps avoid errors in 3D models (Photo credit: Prusa)

3MF is an open source standardized format that allows complex models and precise information to be stored in compressed, human-readable files. It also has built-in protection against common modeling errors, making it ready to print out of the box.

When to use it?

For those who wish to take advantage ofFor users of the latest advances in 3D file formats, 3MF is an excellent choice. It is particularly suitable for complex projects requiring high precision and compatibility with the latest technologies.

STEP: The “Swiss army knife” of CAD formats

Finally,The STEP (Standard for Product Data Exchange) format is widely used in the CAD and engineering fields. Unlike other formats, STEP is not specifically designed for 3D printing, but it plays an essential role in exchanging data between different CAD systems.

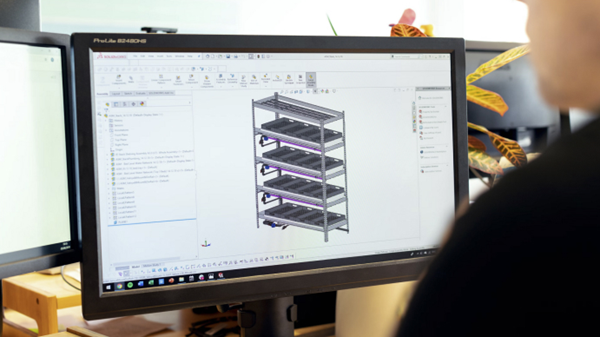

picture6:The STEP format is a very useful format for sharing files between different 3D modeling software

STEP can store not only geometry, but also product structure, assembly and metadata. However, it is not optimized for 3D printing and may contain unnecessary data, complicating the process of preparing the model for printing.

When to use it?

The STEP format is ideal for projects involving complex assemblies or requiring interoperability between different CAD software. It is also useful for editing CAD files before printing.

choose the right oneThe 3D print file format depends on many factors, such as the complexity of the model, the required visual details, and compatibility with the software used. STL remains the default choice for simple designs and maximum compatibility, while 3MF becomes the future standard for more complex projects. OBJ and AMF formats offer advanced functionality for those who need it, while STEP is essential for complex CAD projects.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.