Understanding the reliability of materials designed for use in extreme environments is essential for various high-risk applications. A new study led by the University of Alabama at Birmingham (UAB) and published in Scientific Reports reveals how 3D printed superalloys perform under extreme conditions. The research uses high-resolution imaging and computer simulations to provide new insights into the stability and performance of these materials under high pressures.

Researchers study the stability of 3D printed superalloys under extreme conditions

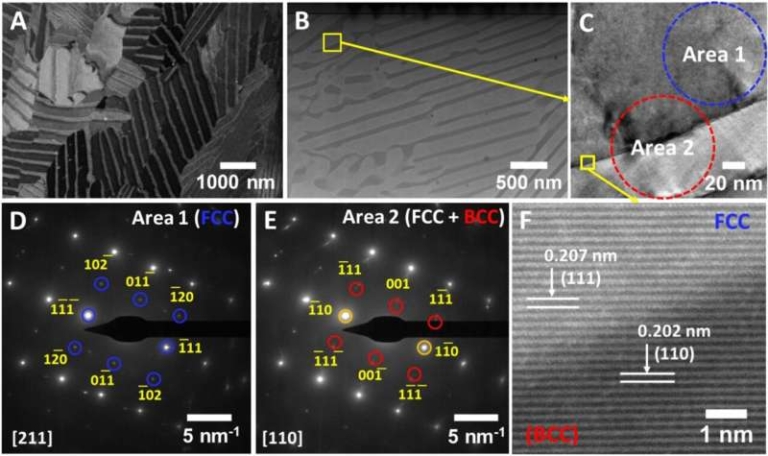

Backscattered scanning electron microscope image (Image source: Scientific Reports (2024). DOI: 10.1038/s41598-024-67422-x)

Advancement of knowledge on materials for extreme environments

Dr. Yogesh Vohra, professor in the Department of Physics and associate dean for research and innovation in the College of Arts and Sciences at the University of Alabama at Birmingham, directs the Center for Additive Manufacturing of Complex Systems in Extreme Conditions (CAMCSE). The center works to develop materials capable of withstanding extreme pressures, temperatures and impacts. These efforts are essential to technological advancement in areas such as aerospace, power generation and nuclear energy.

The study used focused ion beam technology to extract compressed samples of the 3D printed alloy, each just a few nanometers thick. Electron microscopy observations revealed that the nanolayer structure of the alloy remained intact after exposure to extreme pressure, confirming the irreversibility of the phase transition. This discovery is important because it demonstrates the material’s ability to maintain its structural integrity under conditions that often challenge the stability of traditional materials.

Dr. Vohra highlighted the importance of understanding the fundamental structural mechanisms that lead to the high strength and ductility of 3D printed alloys. “In particular, how changes in crystal structure under high pressure affect the mechanical properties of 3D printed alloys,” explains Vohra. The study’s electron microscopy observations are pioneering because they confirmed that the nanostructured layers remained stable under extreme pressure, with no change in chemical composition.

Impact on high-risk applications

This research has considerable implications for the design and application of additively manufactured materials under extreme environmental conditions. The findings could advance the development of materials for aerospace applications and in power plants, where high temperatures and pressures are the norm. Additionally, the stability of these 3D printed alloys in ultra-high speed impacts and high radiation environments, such as those found in nuclear reactors, suggests their potential for use in building solid structures capable of withstand harsh conditions.

Vohra emphasized the collaborative nature of the research, noting that it “represents the collective expertise of four different academic institutions in 3D printing of superalloys under extreme conditions.” This interdisciplinary approach not only drives high pressure-induced changes in the understanding of crystal structure, but also provides results. valuable educational opportunities for UAB graduate students.

Setting new standards in materials science

The research conducted by the UAB and CAMCSE teams highlights the importance of collaboration between scientific and technical disciplines. By studying the behavior of 3D printed superalloys under extreme conditions, this research sets a new benchmark for material performance in high-pressure environments. Lessons learned from this research are expected to influence the design and development of future materials, paving the way for innovation in industries that depend on the stability and durability of materials under extreme conditions.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.