The Evolution of RIM Treatment Machines: Balancing Efficiency, Cost, and Quality in the Manufacture of Rim Products

The manufacture of rim products is a complex process that requires specialized equipment to ensure the production of high-quality wheels for the automotive, motorcycle, and other industries. At the heart of this process are RIM treatment machines, which play a crucial role in shaping, cutting, and finishing rim products. With the advancement of technology, the market has seen a proliferation of RIM treatment machines, each with its unique characteristics, advantages, and disadvantages. In this article, we will delve into the world of RIM treatment machines, exploring the challenges of balancing efficiency, cost, and quality, and providing insights into the selection of the right machine for specific production needs.

Understanding Requirements and Clarifying Treatment Needs

Before selecting a RIM treatment machine, it is essential to clarify specific processing needs. This involves considering several factors, including:

- Product Type: Different types of rims have distinct requirements for treatment machines. For instance, aluminum alloy wheels and steel wheels require different equipment due to their varying material characteristics, hardness, and weight. Understanding the specific needs of each product type is critical in selecting the right machine.

- Precision and Quality: High-precision equipment is generally more expensive, but it is a necessary investment for companies with high product requirements. The choice of machine ultimately depends on the desired level of precision and quality.

- Production Volume: The efficiency of the equipment is particularly important for mass production. For low-yield rims, flexibility and versatility are more critical, while for large-scale production, the degree of automation and equipment efficiency must be considered.

- Material Selection: Choosing the right treatment machine depends on the different materials used, such as aluminum, steel, or composites, as each material has unique cutting characteristics and treatment difficulties.

Choosing the Right Treatment Method

The selection of a RIM treatment machine depends on the treatment technology used. Currently, the market offers various treatment methods, including:

- CNC Lathe: Ideal for turning and treating most rims, particularly in the preliminary stage of rim appearance. CNC lathes provide effective automated treatment, significantly improving production efficiency while maintaining good machining precision.

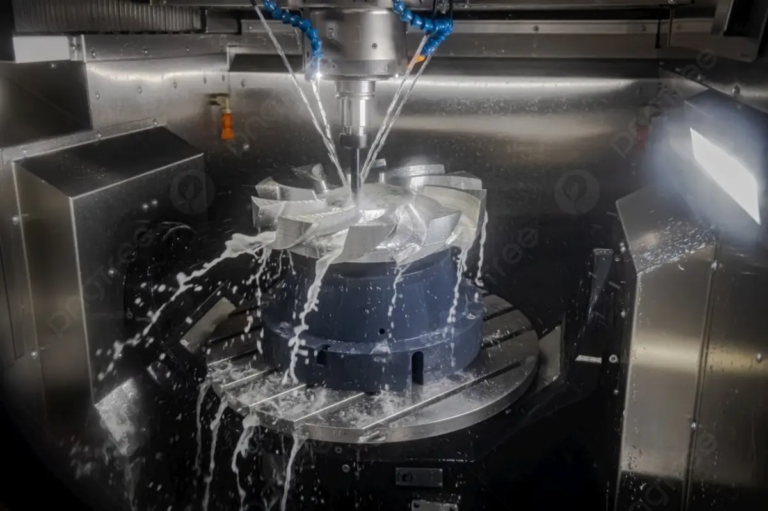

- CNC Milling: Suitable for wheel rims that require high-precision cutting and complex treatment. CNC milling machines can process complex rim designs and are adapted to specific special concepts or complex hole treatment.

- CNC Grinding: Perfect for situations where the edge requires a higher surface finish. CNC grinding machines can finely process high-precision requirements, particularly adapted to aluminum alloys or high-resistance materials.

Balancing Efficiency and Cost

Balancing efficiency and cost is a critical challenge in the selection of RIM treatment machines. Several factors must be considered, including:

- Automation and Labor Costs: Fully automated RIM treatment machines have a high initial investment, but they can significantly reduce manual operation, improve production efficiency, and reduce human errors, ultimately reducing long-term production costs.

- Equipment Price: The price of efficient equipment is generally higher. Companies must choose the right equipment according to their production needs. For mass production, high-efficiency equipment can be more profitable, while for small-scale production or personalized products, equipment with higher flexibility and a moderate price can be chosen.

- Maintenance and Lifespan: The choice of high-quality equipment can guarantee treatment precision and reduce post-purchase costs. The lifespan of the equipment is also an essential factor in evaluating costs. Although high-quality equipment may be more expensive initially, it generally has a longer lifespan and lower maintenance costs.

- Technical Support and Service: Selecting equipment manufacturers with good after-sales service and technical support is crucial. Good service can effectively reduce equipment failure downtime, improve production efficiency, and indirectly reduce production costs.

Innovations in RIM Treatment Machines

The RIM treatment machine market is constantly evolving, with innovations and advancements in technology leading to improved efficiency, precision, and cost-effectiveness. Some of the recent developments include:

- Advanced CNC Systems: New CNC systems offer improved precision, speed, and flexibility, enabling the production of complex rim designs and high-precision parts.

- Automation and Robotics: The integration of automation and robotics in RIM treatment machines has improved production efficiency, reduced labor costs, and enhanced product quality.

- Sustainable and Eco-Friendly Solutions: The development of sustainable and eco-friendly RIM treatment machines has reduced environmental impact, minimized waste, and promoted environmentally responsible manufacturing practices.

Conclusion

The selection of RIM treatment machines is a complex process that requires careful consideration of various factors, including product type, precision, production volume, material selection, and treatment method. Balancing efficiency, cost, and quality is essential in ensuring the production of high-quality rim products. By understanding the specific needs of each production process and selecting the right machine, companies can optimize their manufacturing operations, reduce costs, and improve product quality. As the RIM treatment machine market continues to evolve, innovations and advancements in technology will play a crucial role in shaping the future of rim manufacturing.