Recuity, standardization, caliber, income … Do you clearly distinguish these thermal treatments? The function of thermal treatment is to improve the mechanical properties of materials, eliminate residual stresses and improve the machinability of metals. Depending on the various objectives of thermal treatment, the heat treatment processes can be divided into two categories: preliminary heat treatment and final heat treatment.

1

Preparatory heat treatment

The purpose of preliminary heat treatment is to improve treatment performance, eliminate internal constraints and prepare a good metallographic structure for final heat treatment. Heat processing processes include COPE, normalization, aging, caliber and income, etc.

1) RECOIVE AND NORMALIZATION

The receipt and standardization are used on hot -worked drafts. Carbon steel and allied steel with a carbon content greater than 0.5 % are often recurred in order to reduce their hardness and facilitate the cut; Carbon steel and allied steel with a carbon content of less than 0.5 % are often treated by annealing in order to avoid the tool does not stick when the hardness is too low during the cut, use rather a standardization treatment. The receipt and standardization can still refine the grains and make the structure uniform, thus preparing a subsequent heat treatment. The receipt and standardization are often carried out after the manufacture of the draft and before coarse machining.

2) Treatment of speed

The aging treatment is mainly used to eliminate the internal constraints generated during the manufacture and machining of the sketches.

In order to avoid an excessive transport charge, for general precision parts, just provide an aging treatment before finishing. However, for parts with higher precision requirements (such as the housing of a three -dimensional rage, etc.), two or more aging processes must be provided. Simple parts generally do not require aging treatment.

In addition to the molded parts, for certain parts of low rigidity precision (such as precision screws), in order to eliminate the internal constraints generated during treatment and to stabilize the precision of treatment of parts, multiple aging treatments are Often organized between the draft and the semi-user. finishing. When treating certain tree parts, aging treatment should be organized after the alignment process.

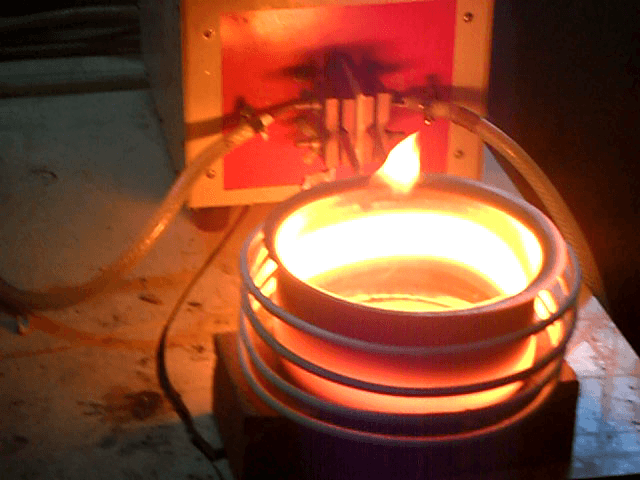

3) Packaging

Declooking and income are a high temperature income treatment after caliber. It can obtain a uniform and fine income sorbit structure to prepare for the reduction of the deformation during the solemn and nitruration of subsequent surface. Therefore, caliber and income can also be used as preparation. thermal treatment.

Since the overall mechanical properties of parts after caliber and income are better, they can also be used as final heat treatment process for certain parts which do not require hardness and resistance to high wear.

2

final heat treatment

Final heat treatment aims to improve mechanical properties such as hardness, wear resistance and resistance.

1) Tim

The caliber includes the superficial caliber and the overall caliber. Among them, the surface caliber is widely used due to the slightest deformation, oxidation and decarburation. The surface caliber also has the advantages of high external resistance and good wear resistance, while maintaining good internal tentacity and strong shock resistance. In order to improve the mechanical properties of parts soaked on the surface, thermal treatments such as caliber and income or standardization are often necessary as preliminary thermal treatments. The general process is as follows: cutting, forging, normalization (receipt), draft, caliber and income, semi-finition, surface caliber, finish.

2) Cementation and caliber

Cementation and caliber are suitable for low carbon and low -allied steels. They first increase the carbon content of the surface layer of the room. After the caliber, the surface layer obtains high hardness, while the nucleus retains a certain resistance, high tenacity and high hardness. plasticity. The cementation is divided into global cementation and partial cementation. During partial cementation, anti-infiltration measurements (copper or veneer in anti-infiltration material) must be taken for non-cemented parts. Due to significant deformation during carburetor and caliber, and the depth of carburetor is generally between 0.5 and 2 mm, the carburetor process is generally arranged between semi-finishing and finish.

The transformation process is generally as follows: outline-to normization-Ébuche and Semi-finition-Cementation and Sole-finition. When the non -fuel part of a partially fuel part adopts the process plan consisting in increasing the margin and eliminating excess layer, the process of eliminating the excess fuel layer must be organized after the fuel and before The caliber.

3) Nitruration treatment

Nitruration is a treatment method in which nitrogen atoms enter the metal surface to obtain a layer of compounds containing nitrogen. The nitruration layer can improve hardness, wear resistance, fatigue resistance and corrosion resistance of the room surface. Since the temperature of the nitruration treatment is low, that the deformation is low and that the nitruration layer is thin (generally no more than 0.6 to 0.7 mm), the nitruration process must be organized the latest possible to reduce deformation during nitruration. It is generally necessary to carry out high temperature income to relieve stresses.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.