Leverage high-precision manufacturing: Why local CNC milling services are your strategic advantage

In today’s fast-paced manufacturing world, the demand for complex, highly tolerant components continues to soar in industries such as aerospace, medical devices, automotive and consumer electronics. Meeting these needs requires advanced features that often exceed the standard machining range. This is Computer Numerical Control (CNC) Milling Shine – and with Local CNC milling service provider like Great Unlock a unique set of benefits that directly affect the success of your project.

Mysterious CNC milling: core accuracy

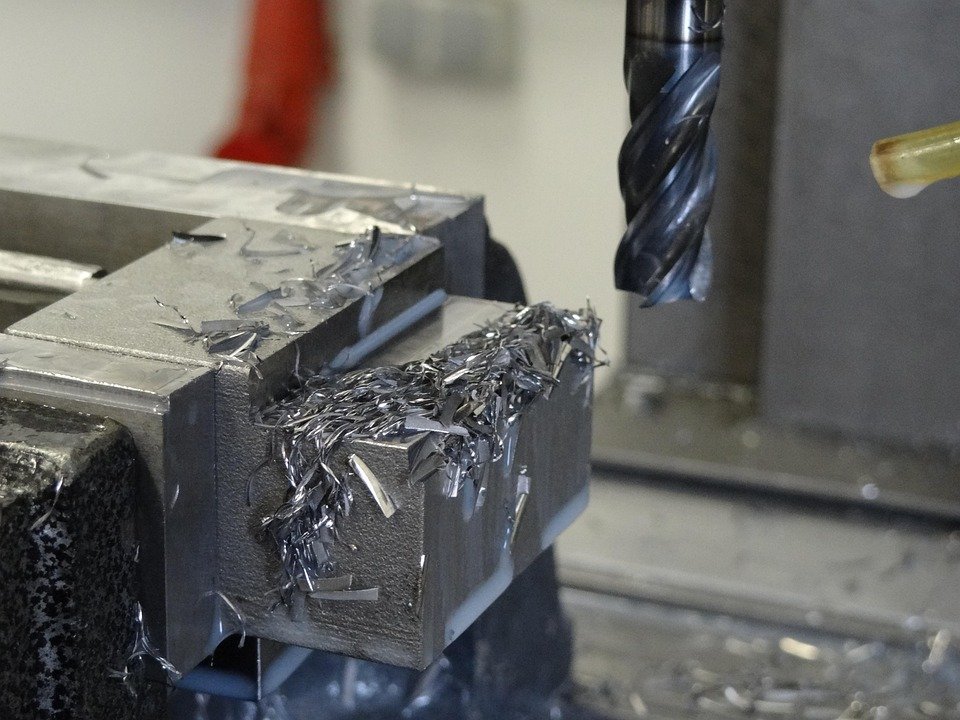

CNC milling is a subtraction manufacturing process, and pre-programmed computer software determines the movement of multi-point rotation cutting tools. This removes material from solid blocks (workpieces) with extremely high accuracy to create complex three-dimensional shapes and features. The core advantages are undeniable:

- Excellent accuracy and repeatability: The tolerability of the CNC machine reaches the fraction of human hair (microns), ensuring that every part in the batch is almost the same.

- Complex geometric shapes become real: Unlike manual machining, CNC milling effortlessly handles complex designs, internal cavity, complex curves and undercuts that would otherwise be impossible or expensive.

- Material versatility: From hard aerospace grade titanium and stainless steel to powerful engineering plastics and lightweight aluminum alloys, CNC milling effectively handles many materials.

- Scalability and efficiency: Once programmed, the CNC machine can produce prototypes, small batches or large productions consistently and efficiently.

Enthralling cases of choosing a local CNC milling service

Choosing nearby providers is not only convenient; this is a strategic business decision:

- Significantly reduce delivery time: Eliminate long-term delays in international transportation. Local services significantly reduce shipping times outside of shipping and finishing parts, thus speeding up your entire project schedule.

- Enhanced communication and collaboration: Time zone differences and language barriers disappear. Face-to-face meetings (if needed), fast phone calls and easier website access promote clearer communication, faster feedback loops and collaborative problem solving. You can view the prototype or discuss key tolerances directly with the engineers who run your work.

- Quality Control and Agility: Physical proximity can be easier to supervise during production. If adjustments are required, visit the facility to quickly ensure changes can be implemented accurately and effectively. Quality inspections become more direct and powerful.

- Supply chain reliability and lower risk: Shortening the supply chain minimizes contacts between international logistics disruptions, customs delays and import and export complexity. You will gain greater predictability and control over your production plan.

- Support your community: Choosing local manufacturing will stimulate the regional economy, create local jobs, and can promote valuable long-term partnerships.

GRESTLIGHT: Your local partner with outstanding performance in the next level five-axis CNC machining

Greatlight is an industry leader when looking for a local CNC milling partner that exceeds basic capabilities. we are not only;we are Professional five-axis CNC machining expertEquipped with state-of-the-art machinery and sophisticated production technology, we aim to solve your most challenging metal parts manufacturing problems.

Why Greatlight five-axis CNC machining is an excellent choice:

-

Advanced five-axis functions: This is our core expertise. Five-axis CNC machining allows the spindle to access parts from almost any direction in a single setup. This eliminates the need for multiple alignments required by traditional three-axis machines, thus:

- Unrivaled accuracy of complex geometric shapes: With excellent accuracy, obtaining complex organic shapes, deep cavity, tilted features and compound curves.

- Significantly improved surface surface: The continuously optimized tool path for five-axis machining reduces tool marking and vibration, resulting in excellent surface quality.

- Reduce setup time and cost: Complicated operations in one setup simplifies production and reduces labor costs.

- Potential for single-part processing: Ideal for creating a total component that otherwise requires assembly, thereby reducing potential failure points.

-

Material mastery and quick customization: Whether you need durable hard steel to make tools, lightweight titanium for aerospace, corrosion-resistant alloys or specialty plastics, we have the expertise and tools to handle it. We’re good at Custom precision machiningprovides fast turnaround without damaging quality to meet your specific material and design requirements.

-

One-stop solution: Simplify your supply chain. In addition to core milling, Greatlight provides a comprehensive Post-processing and completion of services Under one roof. This includes for the hardest metals, surface treatments (such as anodization, electroplating, painting), heat treatment and meticulous quality inspections, even for the hardest metals, grinding, EDM (electric emission processing). We manage the entire process to ensure seamless and consistent quality throughout the process.

- Designed for efficiency and value: We understand the pressures of going public. We combine local agility, advanced five-axis efficiency and internal completion, which means we can provide your complex parts Faster than traditional providers. In addition, our optimized process and competitive positioning enable us to provide solutions Best Valuechallenge the view that high-precision machining must break the budget.

Conclusion: Accuracy, partnerships and performance

Choosing the right CNC milling partner is critical to the success of demanding engineering projects. By selecting one Local provider like Greatyou will have significant advantages in speed, collaboration, control and supply chain resilience. Use this Greglight’s professional five-axis CNC machining capabilities Unlock new possibilities for complex parts design, excellent accuracy, faster turnover speed and excellent finishes. We are committed to becoming one One-stop solution providerhandles the parts from raw materials to finished by rigorous quality inspections, ensuring a seamless and reliable manufacturing experience.

Work with local experts, among which engineering excellence, advanced technology and responsive services are integrated. Don’t compromise on accuracy or schedule. Customize your precision parts now at the best price – Contact us now to discuss your project.

FAQ: Your question about CNC milling service has been answered

Q1: What is the difference between 3-axis, 4-axis and 5-axis CNC milling?

- A1: 3 Axis: The milling cutter moves in the basic X (left/right), Y (front/back) and Z (up/down). The workpiece is usually fixed in one direction. Benefits for simple parts. 4 axis: Add rotation around the X-axis (usually referred to as the A-axis). Allows processing in multiple aspects without manual repositioning. 5 axis: Increase rotation other Axis, most commonly the Y-axis (B-axis) or sometimes the Z-axis (C-axis). This allows the cutting tool to be from any At angles within its range, extremely complex shapes with high precision and finish can be created in a single setting.

Question 2: Why should local services be better than overseas CNC services?

- A2: While cost may be a factor overseas, local services offer unparalleled advantages: Faster turnaround time (No shipping/customs delay), Excellent communication (Shared time zone, language, easier access), Easier collaboration and problem solving,,,,, Better quality control (Direct supervision), Reduced supply chain risk (avoid port delay), and Support local economy. Total cost of ownership (considering delays, errors, communication overhead) often makes locals more efficient and reliable with critical parts.

Q3: What type of material can you use on Greatlight?

- A3: Greglight Machinery various engineering materials, including:

- Metal: Aluminum (alloy), stainless steel (303, 304, 316, 17-4ph, etc.), steel (carbon steel, alloy steel), titanium (2, 5-6AL-4V grade), brass, bronze, copper.

- plastic: ABS, acetyl (POM/Delrin), nylon (PA), PEEK, ULTEM (PEI), polycarbonate (PC), PTFE (Teflon).

- other: We use high-performance alloys and composites. Please contact you for your specific materials to confirm your requirements.

Question 4: Are you working on prototypes and small batch production, or are you just a lot of them?

- A4: Absolutely! GRESTLIGHT is good at Rapid prototyping Using CNC milling, high-precision functional prototypes can be quickly provided for testing and verification. We’re also skilled Low to medium volume generation Run and High volume Manufacturing, leveraging our advanced five-axis capabilities and effective workflows to serve projects of all sizes effectively and economically.

Q5: What "One-stop" Do you provide services beyond CNC milling?

- A5: Gremply provides comprehensive support throughout the manufacturing process:

- Manufacturing Design (DFM) Consultation: Optimize the design for efficient machining.

- Precise turn: Used for cylinder components.

- Grinding & EDM: Used for high precision tolerances, complex features or extremely hard materials.

- finishing: Including anodization (type II, III/custom colors), electroplating (nickel, chromium, zinc), powder coating, painting, passivation, polishing, polishing, bead explosion.

- Heat treatment: Annealing, hardening, tempering, etc.

- Comprehensive quality control: CMM inspection, surface roughness measurement, functional testing, comprehensive reporting.

Question 6: How do you ensure the quality of the parts produced?

- A6: Quality is crucial in Greatlight. We implement strict quality control throughout the process:

- Skilled Engineer: Experienced programmers and mechanics.

- Advanced Metrics: Use a coordinate measuring machine (CMM) to achieve dimensional accuracy, surface roughness testers, optical comparators and other precision measurement tools.

- Process control: Comply with strict processing parameters and inspection protocols.

- Traceability: Each cargo provides certification of materials and detailed inspection reports.

- Certification: We operate in a strict quality management system framework that addresses industry needs.

Q7: How to get a quote for the custom precision part?

- A7: Very easy! Simply contact Greatlime via our website contact form, email or phone. Provides part drawings (preferably in step, IGE or X_T format) or 3D models, as well as details such as material selection, required tolerances, surface treatment specifications and quantities. Our engineering team will quickly analyze your requirements and provide you with competitive quotes and lead times.