1. The status quo of the equipment inverter industry

Whether it is equipment produced by GM or Pognener, GE, Bucyrus, Aiiison Transmissions, Terex, CAT and other companies, whether it is closed or open gear transmission, the gears are reversed, although ‘there is no unified developed countries but unified the National Standard of inverted gears of the equipment, but every company has the same consensus “the equipment must be reversed” in the inverted gears and put implemented according to the relevant standards of their respective companies.

Second, the essence and type of inverted edges

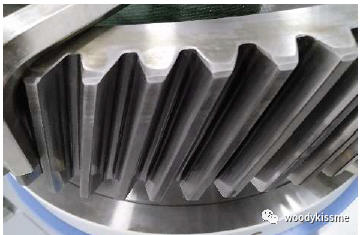

The reverse edge is basically a small back angle, that is, all the sharp corners bare after the equipment processing, and then a small back angle. Inverted edges are divided into the following two types: high tooth eloquence and reverse tooth edges, as shown in Figure 1:

The role and meaning of the reverse gear edge:

1. Reduce noise when gear meshing.

The inverted edge is an important measure to cause noise and damage to the tooth surface of the tooth surface to prevent the tooth surface of the teeth.

2. Improve mesh accuracy and reduce mesh impact.

During the meshing process of a pair of gears, when it first entered the mesh, due to the deformation of the processing and wheel teeth, it was easy to cause mesh impact, so that the vibration increased.

3. Reduce grinding teeth and extend equipment life.

When large and small gears are working, if the top of the tooth is not used, the top of the large gears often appears. This is because the outer turn of the large and small peaks is generally more difficult than the root of the tooth, and the sliding speed here is large. To draw groove marks like glue, and sometimes the same groove marks are also drawn from the top of the small equipment, which has a serious impact on the service life of the equipment.

4. Reduce stress concentration during heat treatment.

The following benefits of eliminating sharp corners of dental top and tooth profile after pouring edges:

1) In the sensory extinguishing of the equipment, the medium frequency, especially the high frequency heating, tends to generate overheating in the hot corner. Therefore, the gear tooth should be reversed before quenching so that the best quenching effect can be obtained during heat treatment.

2) For hard tooth speeds, make a moderate rear angle before the carburetor.

3) Reduce the stress concentration during quenching to reduce and eliminate cracks or quench cracks caused by the heat treatment process, which has an important role in preventing quench cracks.

5. Reduce the risk of teething.

Since the reverse edge is carried out along the bare part of the entire tooth shape, it can avoid sources of fatigue and reduce stress concentration, thereby reducing the risk of teeth.

6. It is conducive to cutting in the scraper and effectively avoids the lack of knife and blade.

Modern heavy-load hard tooth gear processing does not only rely on tooth grinding teeth to ensure precision. Because the hard tooth surface is favored, it is conducive to cutting in the tool, and it can effectively avoid the knife and the knife and the accident. For the development of hard tooth surface, it is very important and necessary to achieve the edge of hard tooth surface before scraping.

7. Beautiful appearance and safe.

After the wheel teeth fall off, it is not only beautiful, but also safer.

The hidden danger of equipment does not fall:

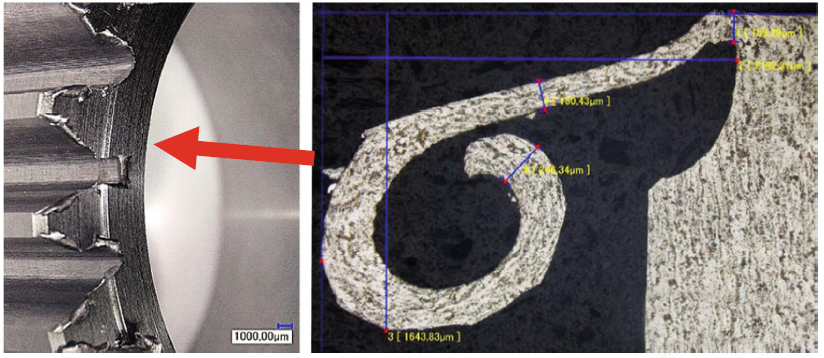

1. No dental contour.

In the long-term use of gears, due to stress concentration, it is easy to cause fatigue micro-cracks, causing more serious collapse tooth at the end of the teeth.

2. Not the top of the tooth.

The flying edge burrs at the tip of the tooth tip and the junction of the gradual opening line are prone, and the grooves similar to the ribbon-like gap on the tooth surface are prone. In the operation of the gear, the top of the tooth of the opponent’s wheel teeth of large and small gears is caused by the top of the tooth of the large and small gears, and the trench marks of a groove of glue will be applied to the root of the tooth.

Inverted edge processing method:

1. Ace follows like the edge of the edge,In fact, it can be said to be the process of removing the terrifying.

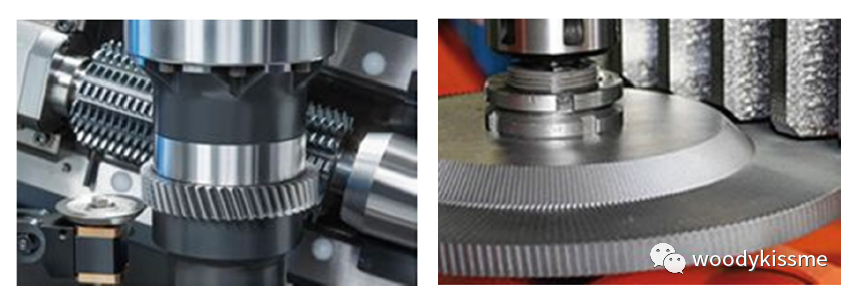

2. Roller chamfer cutting

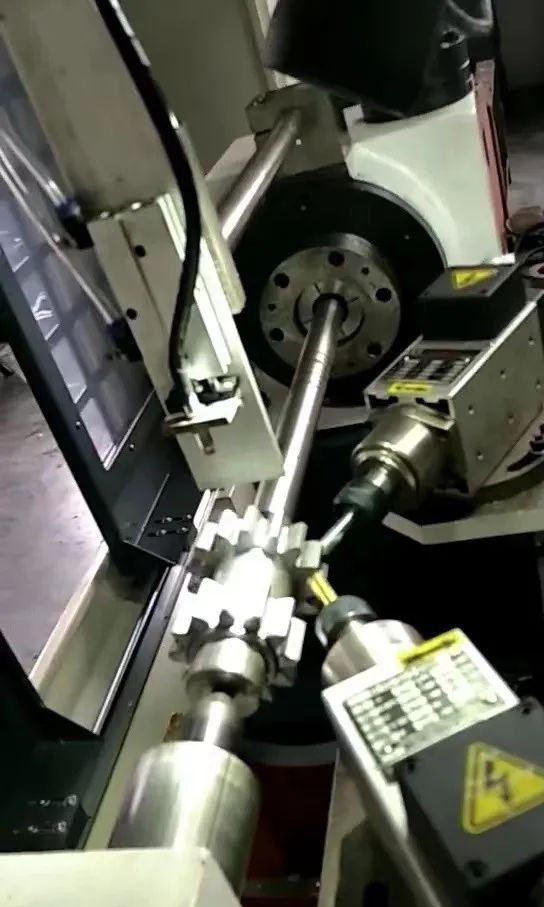

This technology was first applied by Fette. A. In recent years, this technology has also been used in China.

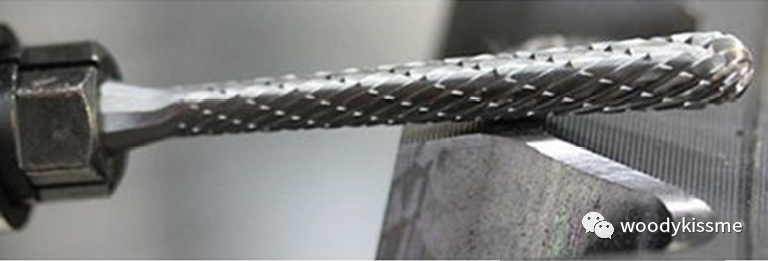

The use of reverse edges of this type of tool is generally two groups, one upper end surface processing and the other lower end surface processing, as shown in the figure above.

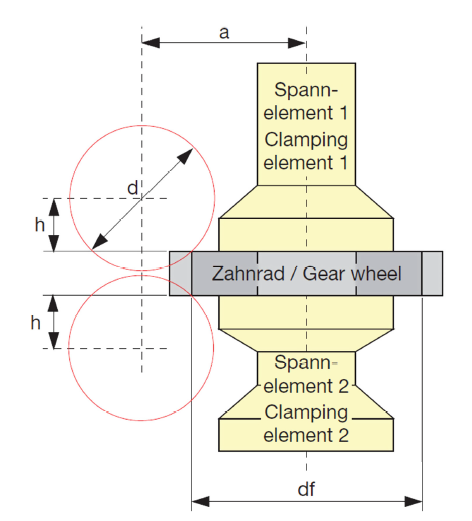

3. Roller chamfering

The reverse knife is transformed into a blade type. Into the depth of the tooth end of the tooth end, clamping the tooth profile metal to the end surface. It is characterized by high efficiency, continuity, good precision, wide application range and easy to achieve automated production, but it must be used on specialized machine tools.

4. Moiling Cutter (“Gratomat”)

The knife moves along the contour of the edge of the teeth (see above). The uniformity of the back angle depends to a large extent on the adjustment of the workers and its adjustment of the device or the wear of the milling machine.

5. Model

The use of sand wheels or cutters is increasing.

Thanks to the help of Internet users (WXID_ILUF1VI64P6222), thank you!

What other gears do you have? Welcome to comment.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.