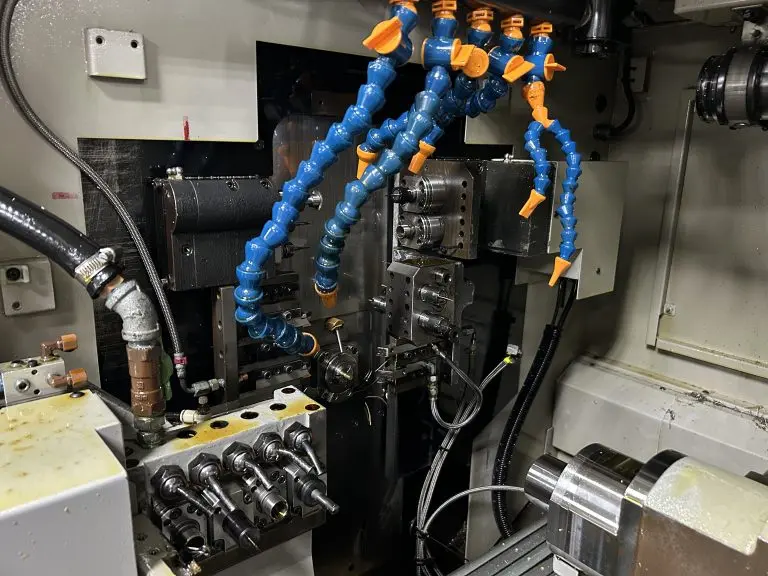

In today’s fast-paced manufacturing environment, accuracy and speed are crucial. This is where Infocus CNC machining services come into play, providing state-of-the-art solutions for businesses and individuals seeking high-quality, customized parts. With its state-of-the-art five-axis CNC machining equipment and advanced production technology, Infocus can handle even the most complex metal parts manufacturing challenges. But what makes Infocus unique is its commitment to provide a one-stop service that includes not only precision machining, but also post-processing and completion services to ensure customers receive their parts under the exact conditions they need.

The versatility of Infocus CNC machining services is evident in its ability to use a wide range of materials. Whether it is aluminum, stainless steel, titanium, or any other metal, Infocus has the expertise and technology to quickly and accurately customize and handle materials. This capability is particularly useful for industries requiring rapid prototyping and production, such as aerospace, automotive and healthcare, where accuracy and reliability are critical.

For those looking for custom precision machining, Infocus five-axis CNC machining is an unrivalled choice. The five-axis function allows for the machining of complex shapes and designs, while traditional three-axis machining will be impossible or extremely challenging. This accuracy also means that parts can be made with complex details and tight tolerances, ideal for applications where fit and function are critical.

Additionally, Infocus understands the importance of cost-effectiveness without compromising quality. By offering competitive pricing, Infocus can provide a wider range of customers from small startups to large businesses. This approach is deeply rooted in the company’s mission of democratizing access to precise processing, empowering businesses and innovators to bring their ideas to life without disrupting the bank.

In addition to its technical capabilities and pricing strategies, Infocus prioritizes customer satisfaction and convenience. The process of ordering custom parts is simplified, with clear communication channels and a responsive customer service team. This ensures that clients are always informed of their project status and can be planned accordingly.

In short, Infocus CNC machining services represent a significant advancement in the field of precision machining. With its advanced technology, commitment to quality and a customer-centric approach, Infocus is expected to meet the evolving needs of industries and individuals seeking high-precision parts. Whether you want to make new products, produce a batch of customized components, or just find a reliable partner for machining needs, Infocus is an excellent choice.

FAQs (FAQs)

-

What materials can be used for Infocus?

Infocus can be used with a variety of metals, including but not limited to aluminum, stainless steel, and titanium. The specific materials they can handle can be confirmed through their sales team.

-

How long does it take to receive a quote?

Typically, Infocus provides a quote within 24 hours of receiving the request. However, the exact time frame may vary depending on the complexity of the project.

-

What is the minimum order quantity for custom parts?

Infocus does not have a strict minimum order quantity, so it is suitable for small and large productions. However, the cost per unit may decrease with larger amounts.

-

Can Infocus provide design assistance or consultation?

Yes, Infocus provides designs for Manufacturing (DFM) services to help customers optimize their production designs to ensure that parts can be manufactured efficiently and accurately.

- What kind of sorting services does Infocus provide?

Infocus offers a variety of after-processing and completion services, including grinding, polishing, anodizing, and more, to ensure that parts meet the required specifications and finishes.