Simply put, tolerance describes the degree of deviation from a specific value that is expected or acceptable. This applies to any manufacturing environment that uses precise measurements, including rapid prototyping manufacturing.

Whether you are already engaged inIf you’ve been 3D printing for a while, or if you’re just starting out and looking at filament specifications, you’ll come across some types of tolerances. For example, Prusament PLA has a diameter of 1.75mm ± 0.02mm, which means any diameter value between 1.73mm and 1.77mm is possible. In other words, “±0.02mm” means that a deviation of up to 0.02mm in the width or narrowness of the filament can be tolerated.

3D printers also have certain tolerances. This means that prints may vary slightly from actual size. The smaller the tolerance (closer to zero), the higher the dimensional accuracy.

In this article,magic monkey networkWillwith everyoneDive into tolerance issues and understand the types of adjustments, what resultsWhy FDM is inaccurate, how to test tolerances and solutions from the initial stages of part design to model post-processing.

A,Why Tolerances Matter

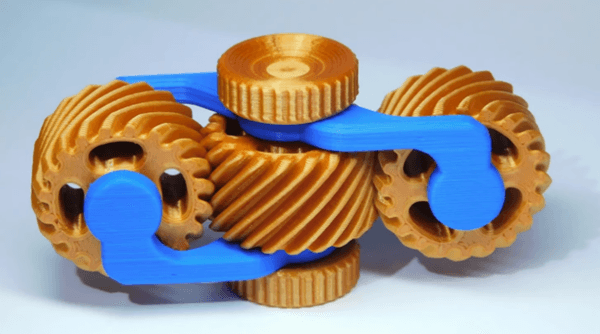

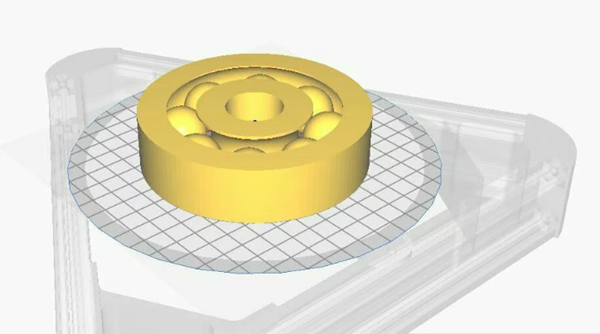

This oneThe parts of the 3D printed top must fit well (Source: Thorin Oakenshield via Printables)

Tolerances in 3D printing are especially important when manufacturing parts that require a tight fit. For example, prints with mechanical assemblies require tighter tolerances than decorative boxes or simple containers. For modeling molten deposits (FDM) In 3D printing you should be aware that tolerances tend to be a bit complicated. For example, features such as holes often need to be enlarged slightly to match the modeled diameter.

Let us make an important clarification: in this article we will refer to tolerances (which must be understood as ranges, e.g.FDM filament has tolerances of 1.73 to 1.77 mm) as well as clearance (a value that describes the space between parts).

When designing parts with small clearances, you need to know your printer’s tolerances and whether you can achieve the required precision. Sufficient space must be left between parts to account for potential dimensional deviations. Small measurement deviations can cause the gaps to melt.

if it’s trueA poor understanding of a 3D printer’s tolerances can result in parts that don’t fit well, or your support structure may completely stick to the print. Additionally, it is important to know that no two printers will have the same tolerances, even if they are the same model. Make sure you find the tolerances that work for your machine and don’t rely on someone else’s tolerance values.

Before we explore how to test and improve your printer’s limits, let’s take a closer look at the types of partners.

Applicable type:

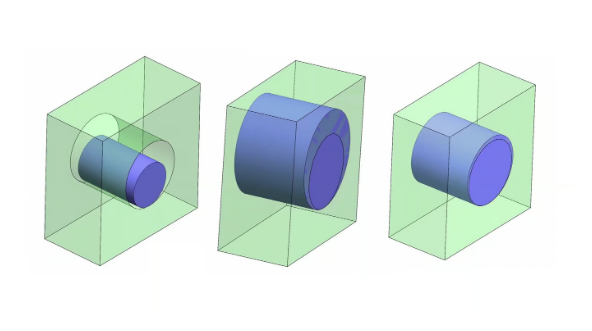

Adjustments with play, interference and transition (Source:Orukalai Engineering, from YouTube)

In most applications, the connection between two components performs a specific function. Let’s give an example.

Consider a nominal diameter of50mm round shaft, which must fit into a round hole with a nominal diameter of 50mm. There are actually three options for how these two parts are connected:

clearance adjustment: The shaft diameter is significantly narrower than the hole diameter, for example, respectively49.8mm and 50.2mm. In this case, the shaft can easily move in and out of the hole and rotate inside it.

tight fit: The diameter of the shaft is respectively the same or slightly wider than the diameter of the hole.50.2mm and 49.8mm. The tree will not fit into the hole without applying a lot of force. Once you’re in, you probably won’t be able to get out without destroying parts. This type of fit is widely used where high concentricity and mutual movement are required (such as for connecting shafts to bearings).

Transition adjustment: The diameter of the shaft is slightly smaller than the diameter of the hole, for example respectively49.9mm and 50.0mm. The shaft will fit into the hole with minimal pressure and remain relatively concentric. Alternatively, the shaft diameter may be slightly larger than the hole diameter, requiring a little more pressure (but not as much as an interference fit).

In fact, there are several combinations allowed for each type of adjustment. The dimensions shown above are examples only. To properly select the fit and design accordingly, there are several international standards such asISO Tolerance), but we won’t talk about that in this article.

However, the type of fit must be determined before setting tolerances. If configured correctly, any two mating parts will perform as intended, regardless of their proximity to the positive and negative range limits.

two,FDM 3D printingReason for inaccuracy

A design like a puzzle requires as much precision as possible (Source:loyalj via Printables)

Besides design errors, which are problems that arise in any manufacturing process,Some key error causes inherent in 3D printing, particularly FDM machines, can also cause errors. Understanding these factors can help improve tolerances if necessary.

1、software error

Convert digital model toDuring STL, some details will inevitably be lost. For example, circular objects are converted to straight surfaces and vertices after being cut. However, the higher the conversion resolution, the lower the dimensional errors of the part.

Slicers can introduce their own errors, depending on their specific algorithms and parameters. How slicers are changingThe vertices of the STL file will greatly affect the appearance of the G-code and therefore the performance of the printer

2、machine error

The 3D printer itself can cause inaccuracies in printed parts in several ways. The motion resolution of a stepper motor is limited, so the accuracy of the motion trajectory can only reach the maximum resolution of the motor. Additionally, typical motors used for FDM 3D printing do not have position control loops, so small position errors accumulate during long print jobs. Most motor drivers also have thermal protection that stops working if it overheats, which can cause the motor to skip stages. The E-step stepper motor is also a critical factor and can cause dimensional inaccuracies if not properly calibrated.

If the printer axes are not sufficiently orthogonal to each other, structural errors will occur. Imagine if you tried to draw a rectangle with non-perpendicular axes, you would get a parallelogram. Then, each time the axis of movement changes direction, a small play is created. The lower the tension in the belt system, the greater the play will be. Belts can also develop other problems over time, such as creep and elongation, which not only reduces tension but can also lead to slippage and missing steps.

When a printer prints a line of filament, it is supposed to produce a uniform width. However, as the nozzle pressure increases, the start of the print line becomes thinner and the end of the print line becomes wider. This is more visible when turning. Typically, overextruding the filament will also result in wider print lines, which can result in overall oversizing, while underextruding will have the opposite effect, and the quality and condition of the filament will also cause d other extrusion issues.

Finally, improper initializationThe Z height can cause an “elephant’s foot” where the first layer extends wider than subsequent layers due to the weight of the print.

Rather than waiting to see if your print is successful, you can avoid problems by testing tolerances and gaps.

3. Testtolerance

This adorable cat also makes a great sizing impression (source:Design via Thingiverse)

testTolerances for a 3D printer start with good calibration of the printer and its extruder. The calibration cube is a useful tool. When ready, print three to five calibration cubes. If you want to have a little more fun, you can also try Dezign’s calibration chat template.

Use calipers to measure each printed model in the same location. Note the orientation of the model (indicated by large letters on the calibration cube). in three directions (X, Y and Z) record at least three measurements each.

For each direction, subtract the smallest measurement from the largest. This number is a good starting point for designing the gaps or space required between printed interfaces. The printer tolerance is the deviation value± half.

For example a calibration cubeY dimensions can be 20.1mm, 20.0mm and 19.9mm. Your deviation is 20.1 to 19.9, or 0.2mm, which means the printer has a tolerance of ±0.1mm.

It should be noted that whatever value you get, it is not necessarily“Permanent” value. Much depends on the current condition of your printer and the materials you are using.

Four,solution

1、design

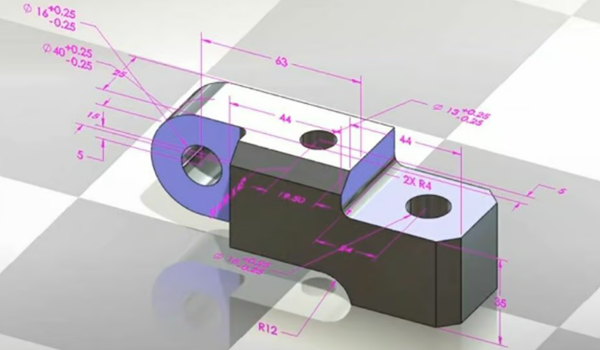

Learn to incorporate expected errors and required tolerances (source:Solid Solutions-A TriMech Company, via YouTube)

Once you understand the potential causes of printing errors, you can take proactive preventative measures to eliminate them as much as possible. Actually you can’t expect a regularFDM printers can produce dimensions accurate to 100 microns or 0.1 mm (conservative estimate). This means that all dimensions should be designed assuming that they can be larger or smaller than this value.

For parts to be assembled, you must design them so that they always fit as expected, even if dimensional errors get out of hand. In almost all cases, this means that if there are two pieces that need to fit together, one must be designed to be smaller than the other. for the standard0.4mm nozzle, here are some general rules of fit based on hole and shaft connections. Remember that you need to experiment and know the actual values of your printer.

clearance adjustment: The difference between the hole diameter and the shaft diameter0.5 mm and more. This results in a theoretical clearance between the shaft and the hole of at least 0.25 mm.

tight fit: The difference between the hole diameter and the shaft diameter is approximately0.2mm or less. This results in a theoretical gap between the two parts of0.1mm or less.

Transition adjustment: The difference between the hole diameter and the shaft diameter0.15-0.4mm. This results in a theoretical clearance between the shaft and the hole of 0.08 to 0.2 mm.

Teardrop holes allow you to print horizontal holes without sagging (Source:Maker’s Muse via YouTube)

Since these rules relate to differences between parts, they can also be used for non-cylindrical parts. When considering non-cylindrical joining parts, such as square holes and corresponding square projections, the above rules can be applied to the difference between the nearest fitting planes. For example, to obtainFor a fit with 30mm square shank set, a clearance of 0.25mm (i.e. 30.5mm square) must be maintained when designing the holes.

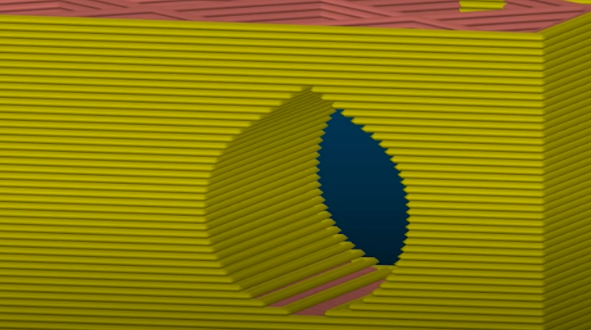

Another key guideline is to consider the orientation of the part to achieve the highest quality. It is best to print the holes horizontally (with the printer mark).The XY plane is parallel). If you need to print a vertical hole, you can use the droplet technique to make the top of the hole pointed rather than completely round. This avoids errors caused by the filament hanging in the air when closing the top of the hole.

Furthermore, due toDue to the layered nature of FDM 3D printing, the accuracy of vertical features is generally lower because they are as thin as the layer height. Horizontal (XY) characteristics tend to be more accurate because they are only limited by the resolution of the stepper motor and belt, as explained in the previous section.

2. Software

Some printing inaccuracies can be minimized using a special slicer function (source:Paul via MathCodePrint)

There are several software solutions that can help improve printing accuracy. When printing part slices with the highest precision, you typically need to use slower kinematics (speed, acceleration, and jitter), smaller layer heights, and active part cooling. We recommend that most office printers print at speeds lower than60 mm/s, acceleration less than 3000 mm/s2 and jitter less than 15 mm/s.

In the slicer configuration, some unique features can help improve dimensional accuracy. The following examples are forCura, but most slicers have similar functionality.

First of allPrint the exterior wall,AgainPrint the interior wall:Print firstexterior wallwhich can theoretically improve dimensional accuracy as it will not be affected by interior walls or infills.

Stove: This feature allows the printer to stop extruding at the end of the movement and rely on the remaining pressure in the nozzle to print the remaining filament during the movement.

Horizontal expansion: This function increases or decreases the size of a part by a specific percentage. Ideally this would fine-tune the print size, but in reality it is only useful if the overall print size is too small or too large. For example, if the overall size of the print is acceptable and only the holes need to be adjusted, a different method should be used, such as“Horizontal hole expansion” function.

Adjust print settings: Heated bed temperatures that are too high can cause dimensional accuracy issues, like the elephant’s foot mentioned earlier. Likewise, if the extruder temperature is too high for a particular filament, this can also cause stringing and staining, which can affect gaps.

After deciding,The linear advance feature in Marlin (and some other firmware) adjusts the filament flow based on the intended print movement. This feature predicts changes in nozzle pressure that could lead to inconsistent extrusion and adjusts accordingly. It converts inconsistent line widths into more uniform lines, improving the dimensional accuracy of your prints. Linear feed has a similar effect to adjusting slip in a slicer, but is generally easier to adjust.

3、machine

Proper calibration of your machine will significantly improve printing accuracy (source:GeekWareSoft via YouTube)

Perhaps the most important way to achieve the greatest printing accuracy and meet tolerances is to calibrate the printer itself. A poorly calibrated printer will result in parts that are not straight, incorrectly sized, or poorly fitted together. It is also important to remember that desktop computers intended for leisure3D printers are never fully calibrated from the start, even when pre-assembled, over time they require additional calibration as part of routine maintenance; Although professional-grade machines can compensate for this to some extent, they still require regular maintenance and calibration.

The importance of machine calibration cannot be underestimated, as incorrect calibration can undo all of your design and cutting efforts to meet tolerance requirements. The most important components for calibration are the extruder andE step, and it is always crucial to start with a good first coat. You can use a test pattern to verify that everything is working correctly before you start printing.

It is also important to select a high-quality nozzle and filament, because the dimensional accuracy of the part largely depends on whether the width of the extruded filament meets the requirements. Cheap filaments often have tighter tolerances, which can cause extrusion irregularities and result in an uneven surface on the print. The best filaments have tight tolerances, few impurities and are stored properly. Large deviations in filament diameter or poorly machined nozzles can have a direct impact on the tolerances of your printed parts.

Finally, aging components can also reduce printer accuracy. Make sure the printer belt is tight and there is minimal wear on the rods or bearings. Otherwise, tighten or replace the part. Ask your printer manufacturer how best to accomplish this task.

4、post-processing

This T. rex skull required some post-processing before the lower half could be installed (Source:All 3DP)

Even with proper calibration, design, and special cutting configurations, parts can still fall out of tolerances. In this case, post-processing is necessary to bring it into compliance.

There is no shame in accepting the need to reprocess parts. Even with a high-precision CNC machining center that costs hundreds of thousands of dollars, sometimes post-processing is required on the part to make it meet specifications.

It should be noted that post-processing generally refers to subtraction, so it is more applicable to oversized parts than to undersized parts. Here are some key tips for reducing rooms to the desired size:

The parts were sanded and filed to remove bellbottoms, support residue, and other printing residue.

As you post-process your parts, continue measuring them until you reach the desired dimensions.

Drill or ream holes.

Avoid using supports as much as possible. It is much easier to re-drill the hole than to pry the small bracket with pliers.

Finally, it must be admitted that certain dimensions and geometric tolerances (GD&T requirements are not easy to meet on a DIY level. For example, testing and correcting runout in a 3D printed axle is beyond what most setups can achieve. But hopefully following the guidelines in this article will save you from unnecessary post-processing and reprinting!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.