About high-speed cutting machine tools

The high -speed cutting treatment is the most important modern manufacturing technology. Since the mid-1980s, the development of high-speed cutting machine tools has become the dominant current of the development of international industrial tools. In general, a complete system of machine tools includes mainly: high static / dynamic support components (the basic structure of the machine tool); and an accelerated acceleration advance in accelerating the acceleration of the power system;

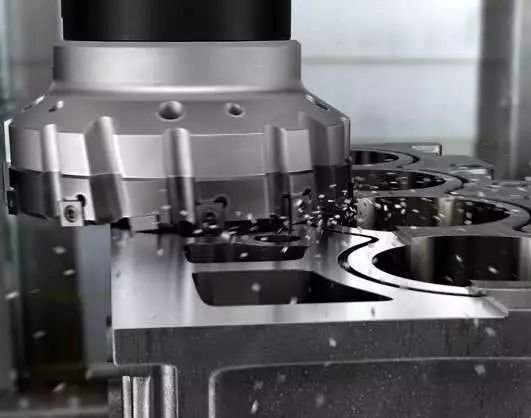

High speed electric spindle view

1

Basic structure of the tool-tool

The basic structures of machine tools include the body, the base and the columns. Many beds of high speed machine tools use polymer concrete (or artificial granite). Another measure to improve the rigidity of the machine tool is to reform the structure of the bed.

The brooch at high speed is one of the most critical technologies to obtain a high speed cut. With the continuous improvement of zipper speed requirements in industry, high -level spindle technology has grown rapidly in recent years. Currently, the main axis speed processing center is increasingly popular at 10,000 ~ 20,000r / min. Min is also under development and development. Due to the high speed of the spindle at high speed, the main axis parts produce vibrations and deformation under the action of the centrifugal force. Strict control must be strictly controlled. For this reason, the following performance requirements are placed on the pin at high speed:

-

High speed and high speed range.

-

Enough rigidity and high precision of rotation.

-

Good thermal stability.

-

High power.

-

Reliable tool installation card performance.

-

Advanced lubrication and cooling system.

-

Reliable pin monitoring system.

2

High -speed cutting knife

High speed cut is a relative concept, which is generally considered 5 to 10 times that of conventional cutting speed. The cutting speed range at high speed is linked to treatment methods and the density of room materials.

HSC = high speed cut

HSM = high speed mass mass

HSD = high speed mill

HST = Drill at high speed

HSTM = BUT High -speed

The safety of high -speed cutting tools must be taken into account:

-

Tool resistance

-

Holding knife clip

-

Tight blade

-

Knife and balance

The sustainability of a high -speed cutting tool is linked to the following factors:

-

Tool material

-

Peak structure

-

Cut

-

Way of walking

-

Cooling conditions

-

Part material with a corresponding knife

Tool wear:

Bond and wear: the phenomenon of the knife and the material of the part contact the atomic distance. In the real contact area of the friction surface, the high pressure and high temperature effect produces plastic deformation, resulting in “cold welding”.

Disclosure and wear: the two chemical solids (carbon and iron, etc.) are placed together.

Solubility and wear: similar to diffusion wear, are chemical wear, based on the theory of dissolution thermodynamics.

Oxidation and wear: at a high speed cut and a high temperature, certain elements in the material of the tool and certain environments around certain environments (oxygen in the air, sulfur in the cutting fluid, chlorine chlorine) are Chemically detected, generating different oxidation and adhesive films membranes, and some of them are excited.

Tool damage:

The inconsistent mechanical fatigue and heating fatigue caused a crash, a coat, cracks and crisp breaks.

Knife equipment:

High -speed milling tools mainly include hard alloys, coating tools, metal ceramics, ceramic, cubic boron nitride (CBN) and diamond knives.

The performance of the material to the tool:

Durness and abrasion resistance: it must be higher than the hardness of the room material, generally above HRC60; The higher the hardness, the higher the abrasion resistance.

Power and tenacity: Resist the cutting force, impact and vibrations, prevent the break and the crisp crash of the knife.

Heat resistance: it can withstand a high temperature and an antioxidant capacity.

Treatment performance and economy: Have good forging, heat treatment, welding treatment performance and grinding and costs.

1 and 1

Hard alloy

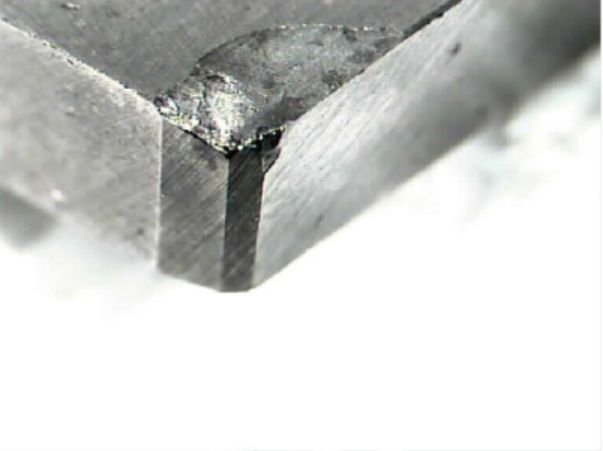

The image shows the Ultra-Fin-fin 45 # Hard Crystal Alloy Tool # Before Quality Steel (HRC35-40), the surface of the rear knife V = 300m / min

High speed strawberries generally use fine grains or ultra-fine hard crystal alloys (grain size 0.2 ~ 1 μm). 6%.

2

Coating knife

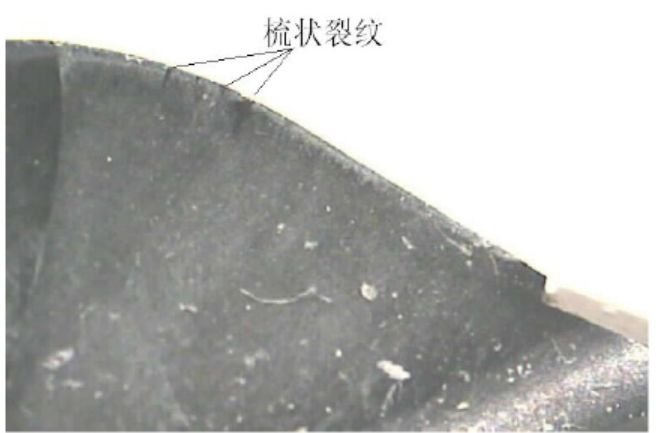

The image shows the overall hard alloy knife of the coating

(VC = 1200m / min, AP = 5 mm, AE = 12 mm)

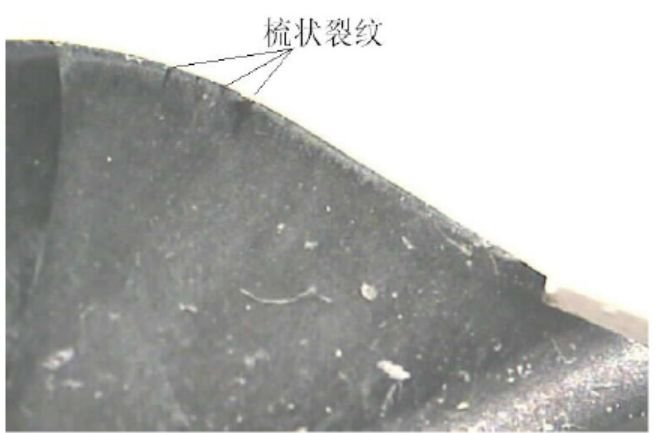

Mechanical fatigue cracks and thermal cracks (high speed aluminum alloy)

The high speed mill uses a large number of coating tools. 涂层材料有 ticn 、 tialn 、 tialcn 、 cbn 、 al2o3 、 cnx 等 , 通常采用多层复合涂层 , , , ticn + al2o3 + tintiticn + al2o3 , ticn + al2o3 + hfn, tin + al2o3 , ticn, tib2 , tialn / tin and tialn. Tialn hard alloy coating deposited with physical gas has good cutting performance during high speed milling.

3 and 3

Metal ceramics

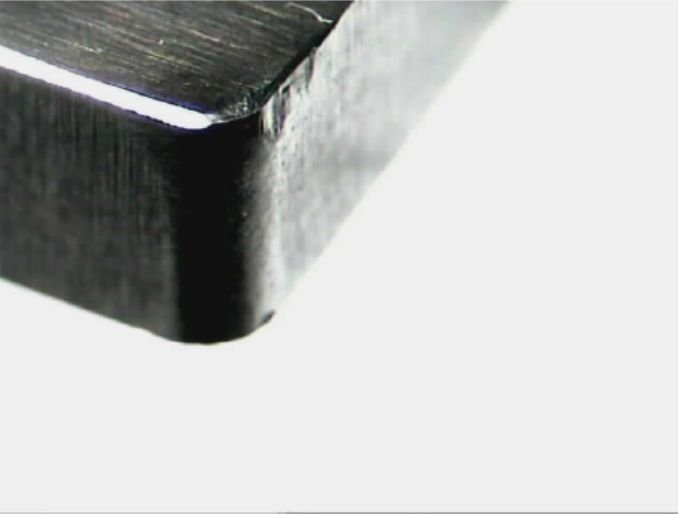

The image shows before the SG4 Steel Broye 45 # ceramic tool (HRC45-50), the surface of the rear knife is carried, V = 400m / min

Fundamental Ceramics Fundamental Tic mainly resistant (ICT + Ni or Mo), a strong strong strong fundamental ceramic (ICC + TAC + WC + CO), the improved TICN Fund belongs to TICN + NBC), compared to hard quality alloys to improve The high temperature performance of the tool, suitable for alloy steel and high -speed processing melting.

4

Ceramic knife

The image shows the ceramic tool processing JX-1 GH169 Limits V = 62.5 m / min

Ceramic tools are divided into three types: alumina ceramics, silicon nitride ceramics and composite ceramics. Tenacity, thermal conductivity and heat resistance have a low impact, adapted to the treatment of steel parts. SI3N4 basic ceramics represent approximately 1/3, which has strong resistance, tenacity to fracture and a heat resistant impact more than al2o3 ceramics. The SI3N4-AL2O3 composite ceramics (SIALON) has high resistance and tenacity to fracture, high antioxidant and anti-tempture antioxidant degeneration, a training tutorial with high-speed treatment technology, but not suitable for parts in parts steel. Roaring treatment speed in cast iron and nickel -based alloy.

CBN knife

It has high hardness, high heat resistance, high chemical stability and thermal conductivity, but the resistance is slightly lower. Depending on the weight score, CBN with low content content (50% ~ 65%) can be used for the fine treatment of hard steel. High content CBN (80% ~ 90%) can be used for high speed grinding melting, rough treatment and semi-test treatment of hard steel.

Diamond

Divided into natural diamonds and Polyc crystal diamonds. materials. The more the grains are rocket, the better, the aluminum alloy with a high level cut of Si is less than 12%, the tasks with a grain size of 10 ~ 25 μm.

3

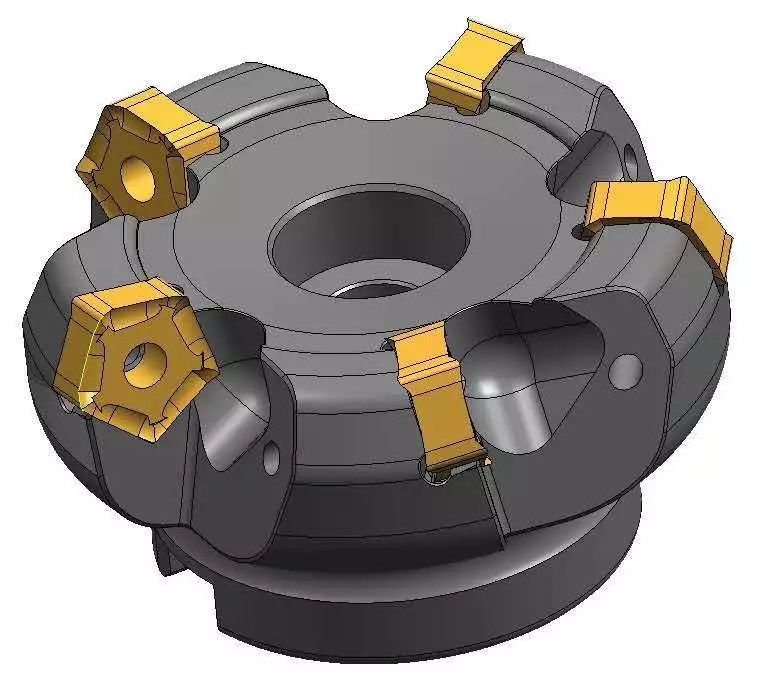

Tool structure

Enumerate several typical high speed milling tools, which are divided into global quantity classes and quantity of files. Small diameter strawberries are generally used in the overall form, and large diameter strawberries are a backrest. High machine tools have certain restrictions on the diameter of the tool. The tightening blade, so the global type is more commonly used. When the tool-tool is relatively low and can provide a large torque, it can use a lighting type striker.

The distance between the milling knife is defined as the distance from Zhouxiang of the two knives adjacent to the teeth, which is affected by the number of teeth of the striker. The short section distance means that more blade teeth and medium -sized crumbs are allowed to allow high metal elimination rates. Generally used for cast iron grinding and medium load steel parts, generally the first choice for high speed strawberries. The large number of cutting teeth is large and the space of capacity is important. The ultra-density spacing space is small, which can withstand a very high power speed.

4

Application of broadband cutting tools

Aluminum alloy: The diamond is most suitable for high speed cut. However, complex tools can be aluminum and its alloys with an ultra-thin crystal alloy and its coating tool.

The treatment of steel and melting and its alloy: a ceramic knife based on AL2O3 is suitable for cutting high speed and high speed; – Cutting the cast iron and its alloy, but not adapted to steel based in unsuitable steel – steel based on WC; Complex tools can treat steel and melting.

Super alloy machining: rigid and reinforced alumina base and ceramic tools based on SI3N4 and Sialon ceramic tools are suitable for treatment of alloys. PCBN tools can be treated at a cutting speed of 100-200 m / min. Complex tools can be used for hard with high crystal alloys and their coating tools.

Titanium machining alloy: generally, hard crystal alloys Super -based on WC and diamond knives can be used. Use a well lubricated cutting fluid to get better results.

5

Blade

1 and 1

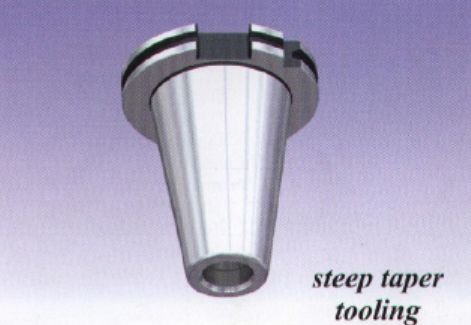

Bt knife handle

Unique contact BT handle (cone cone 7:24)

Handle of the BT and graphic knife of the joints of the main axis

Noticed:

The best rotation range of the BT40 knife handle is 0 ~ 12000r / min

12000 ~ 15000r / min can always be used.

2

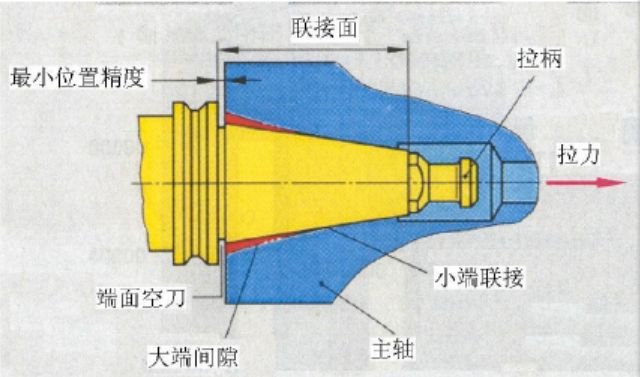

HSK knife handle

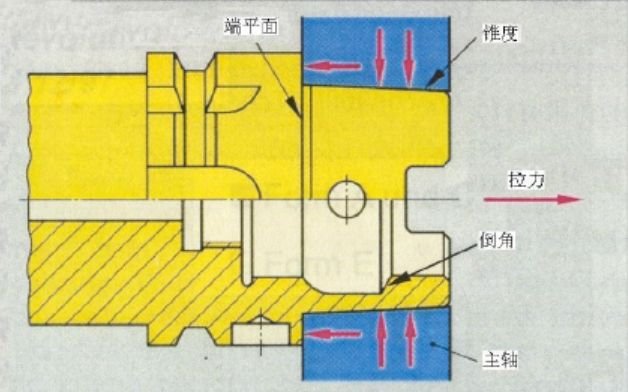

The HSK system with double floor contact (the conicity of the handle 1:10)

HSK knife handle and main axis seal graphics

Noticed:

The best speed range of the HSK-63A knife handle 0 ~ 30000R / min

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.