CNC Thread Milling: Dive into the Basics

In the world of CNC machining, creating precise and strong threads is crucial. While traditional tapping methods have their place, CNC thread milling has become a powerful and versatile technology for producing high-quality threads in a variety of materials. This article takes a deep dive into the basics of CNC thread milling, exploring its benefits, process, programming considerations, and best practices.

Hongguang is a professional five-axis CNC machining manufacturer. Hongguang has advanced five-axis CNC machining equipment and production technology. It specializes in solving metal parts manufacturing problems and can also provide one-stop post-processing and finishing services. Most materials can be quickly customized and processed. For customized precision machining, Honglaite five-axis CNC machining is the first choice. Customize your precision parts now at the best price!

What is CNC thread milling?

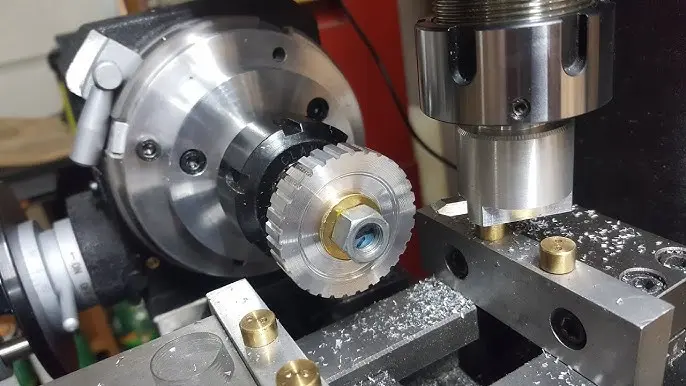

CNC thread milling is a machining process that uses a rotating milling cutter to create threads on a workpiece. Unlike tapping, where a tap is forced into material to form a thread, thread milling uses a controlled helical path to remove material. This allows for better control of thread geometry and offers several advantages over traditional threading methods.

Why choose thread milling over tapping?

Several factors make CNC thread milling an attractive alternative to tapping:

- Versatility: Thread milling excels at machining hard or difficult-to-machine materials such as stainless steel, titanium and hardened alloys, where tapping can be problematic due to broken tools or poor thread quality.

- Improve thread quality: CNC thread milling produces high-precision, consistent threads with an excellent surface finish. Controlled cutting action minimizes tearing and burrs, improving thread strength and functionality.

- Greater thread depth control: Thread milling allows precise control of thread depth, which is especially important for blind holes where tapping is difficult to control.

- Reduce tool breakage: Because thread mills gradually remove material, the risk of tool breakage is significantly reduced compared to relying on forceful tapping. This is particularly useful when working with expensive or brittle materials.

- One knife, many sizes (possibly): Depending on the tool and thread type, a single thread milling cutter may produce different thread diameters with the same pitch. This reduces tool inventory and setup time, increasing efficiency and cost-effectiveness. This more often applies to internal threads.

- Improved chip evacuation: Thread milling produces smaller chips that are easily ejected from the cutting area, reducing the risk of chip clogging and increasing cutting efficiency. This is especially useful for deep hole threads.

Thread Milling Process: Step-by-Step Overview

The CNC thread milling process typically includes the following steps:

- Pilot hole preparation: First drill a pilot hole in the workpiece that is smaller than the minor diameter of the thread. The accuracy of this hole is critical for accurate thread formation.

- Tool selection: Choosing the right thread milling cutter is crucial. Key factors include thread size, pitch, material, and internal or external threads. Different types of thread milling cutters exist, including single-point, multi-point, and full-contour milling cutters.

- CNC programming: Create specific CNC programs to define the tool’s path. The program instructs the machine to move the tool along a precise spiral path, gradually removing material to form threads. This involves precise synchronization of the rotating axes, depending on the machine configuration.

- Cutting parameters: Choosing the correct cutting parameters such as cutting speed, feed rate and depth of cut is critical to achieving optimal thread quality and tool life. These parameters are material dependent and should be adjusted according to the manufacturer’s recommendations.

- Thread milling operations: The CNC machine executes the program, guiding the tool along the programmed path. The tool gradually removes material with each pass, gradually forming the thread profile.

- Deburring (optional): After thread milling, a deburring operation may be required to remove any sharp edges or burrs that may have formed during the machining process.

- Quality control: Finally, inspect the threads to ensure they meet the required specifications, including thread diameter, pitch, and depth.

Programming considerations for CNC thread milling

Thread milling CNC programming can be complex and requires a thorough understanding of G-code programming and thread geometry. Key considerations include:

- Helical interpolation (G02/G03): The G02 (clockwise) and G03 (counterclockwise) instructions are used to create the helical path required for thread milling. The program must specify the circle’s center point, radius, and Z-axis motion (pitch) for each rotation.

- compensation: Tool radius compensation (G41/G42) is essential to ensure accurate thread dimensions. The program needs to take the tool radius into account to obtain the required thread profile.

- Thread milling cycle (G87/G88 – depending on the machine): Some CNC machines offer a dedicated thread milling cycle (G87 or G88, depending on the machine controller) that simplifies programming. These cycles automatically calculate the helical path and compensate for the tool radius.

- Climb milling vs. conventional milling: It is important to decide whether to use climbing (milling down) or conventional (milling up). Climb milling generally provides better surface finish and longer tool life. However, for certain materials or applications, conventional milling may be preferable.

- synchronous: For four- and five-axis machines, synchronization between the rotary and linear axes is critical to achieve precise helical motion.

Best Practices for Successful Thread Milling

- Use sharp, high-quality knives: Dull or worn tools can result in poor thread quality, increased cutting forces and shortened tool life.

- Stay rigid: Make sure the workpiece and machine are securely clamped to minimize vibration and chatter. Vibration can have a negative impact on thread quality.

- Use appropriate cutting fluid: Cutting fluid helps cool and lubricate the cutting area, reducing friction and extending tool life.

- Accurate speed and feed: Choose the speed and feed appropriate for the material and tool.

- Proper pilot hole preparation: Precisely sized and positioned pilot holes are critical to good thread quality.

in conclusion

CNC thread milling is a powerful and precise technology that produces high-quality threads in a variety of materials. Its versatility, accuracy and reduced risk of tool breakage make it a valuable asset in modern CNC machining applications. By understanding process basics, programming considerations, and best practices, you can leverage CNC thread milling to create strong, reliable threads that meet your project’s demanding requirements. GreatLight’s advanced five-axis CNC machining services can assist with a variety of thread milling projects. Contact us today to discuss your specific needs and learn how we can help you achieve your manufacturing goals with precision and efficiency.

FAQ Section: CNC Thread Milling

Q: Which materials are best for CNC thread milling?

A: CNC thread milling excels at machining hard and difficult-to-machine materials such as stainless steel, titanium, Inconel and hardened alloys. It also works on softer materials like aluminum and brass.

Q: Can you mill internal and external threads?

Answer: Yes, CNC thread milling can be used for internal threads (inside the hole) and external threads (outside the cylinder). Each application uses a different tool type.

Q: What is the difference between a single-point thread milling cutter and a multi-point thread milling cutter?

Answer: A single-point thread mill has a cutting tooth that forms the entire thread profile through multiple passes. Multi-point thread mills have multiple cutting teeth that typically form the entire thread profile in one pass or less. Single-point milling is suitable for large threads, and multi-point milling is suitable for speed.

Q: How accurate is CNC thread milling?

A: CNC thread milling can achieve very high accuracy, typically within a few thousandths of an inch. Accuracy depends on the capabilities of the machine, the quality of the tool and the accuracy of the CNC program.

Q: What is the typical tool life of a thread mill?

Answer: Tool life varies depending on the material being processed, cutting parameters and tool quality. However, a well-maintained thread mill can produce many threads before needing to be replaced or re-sharpened.

Q: Is CNC thread milling more expensive than tapping?

A: CNC thread milling can be more expensive than tapping, especially for high-volume production where tapping can be done. However, the benefits of thread milling, such as improved thread quality, reduced tool breakage and versatility, often outweigh the cost difference, especially for challenging materials or complex geometries.

Q: What parameters need to be specified when ordering thread milling services?

A: Important parameters include thread size (e.g., M8x1.25, 1/4-20 UNC), thread type (female or external), material, thread depth, and any special requirements for thread fit or finish. Providing detailed drawings and specifications is critical to ensuring accurate thread milling.