In today’s fast-paced manufacturing world, precision and efficiency are paramount. Among the various tools that facilitate this need, the CNC (Computer Numerical Control) screw grinder stands out as a remarkable piece of machinery that combines sophistication with unparalleled accuracy. This article delves into the intricacies of CNC screw grinders, exploring their significance in modern manufacturing, the technology behind their precision, and the benefits they bring to various industries.

## Understanding CNC Screw Grinders

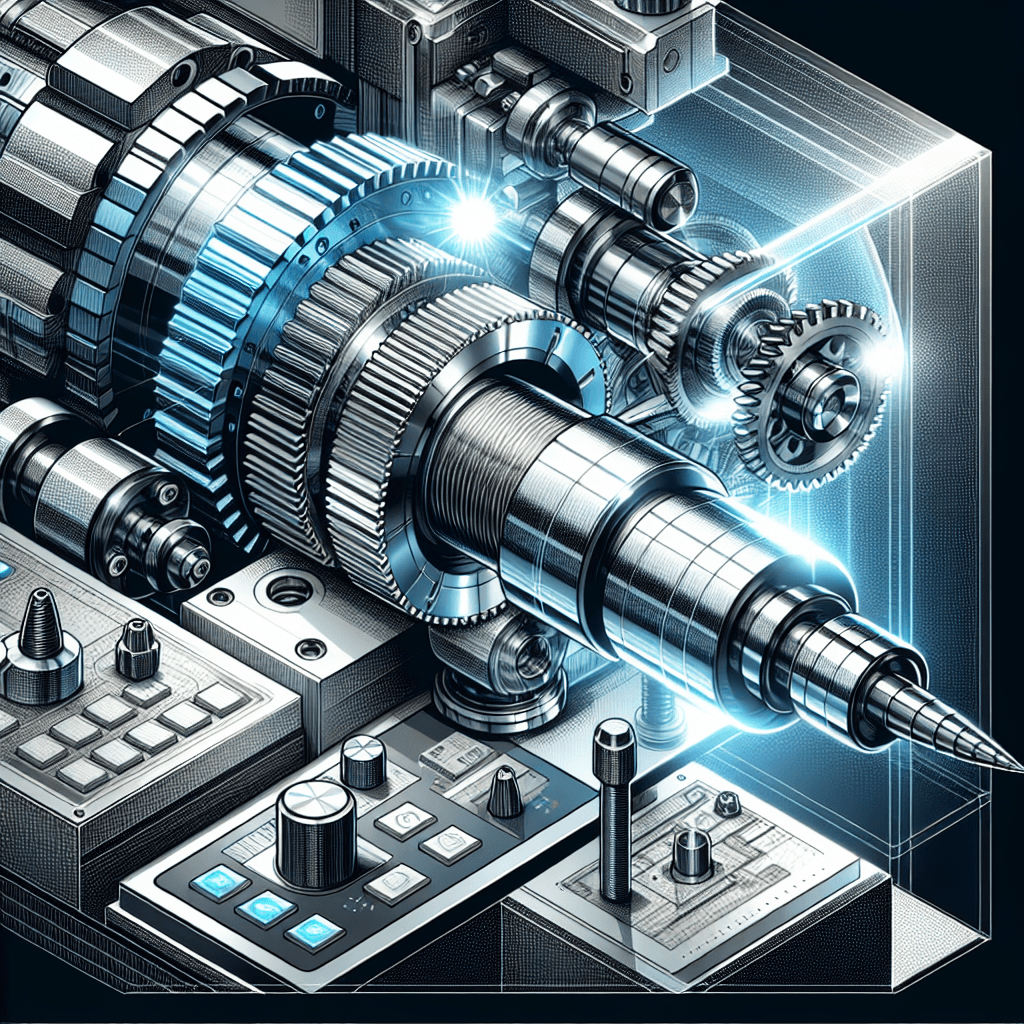

CNC screw grinders are specialized machines designed to produce high-quality, precision screws and other threaded fasteners. These machines utilize computerized control systems to automate the grinding process, ensuring consistency and accuracy in dimensions, shapes, and surface finishes. The use of CNC technology allows for complex geometries that would be challenging to achieve with traditional grinding methods.

### The Role of CNC Technology

CNC technology revolutionized the way manufacturing processes are carried out. It harnesses computerized systems to control machinery, eliminating the potential for human error while enhancing productivity. In screw grinding, CNC systems take the operator’s design specifications and translate them into precise movements of the grinding tools. This level of automation not only speeds up production but also allows for intricate designs that are critical in applications requiring high precision.

## Key Components of CNC Screw Grinders

### 1. Grinding Wheel

The grinding wheel is the heart of the CNC screw grinder. Designed to remove material from the metal stock, the wheel must be chosen carefully based on the type of material being processed, the desired finish, and the specific grinding operation. Various materials and bonding agents can be utilized to construct grinding wheels, enhancing their effectiveness for different applications.

### 2. CNC Control System

At the core of CNC screw grinders is the control system that interprets programming language and commands. This system manages the movement of the grinding wheel and workpiece, ensuring that every detail is executed with precision. Advanced CNC systems come equipped with features like adaptive control that enables real-time adjustments, further increasing accuracy and efficiency.

### 3. Workpiece Holding Mechanism

To achieve the high precision required in screw grinding, workpieces must be securely held in place during the grinding process. This is typically accomplished through sophisticated holding fixtures or vises that eliminate vibration and movement. Ensuring stability during grinding is crucial, as any minute shifting can result in dimensional inaccuracies.

### 4. Cooling and Cutting Fluids

During the grinding process, significant heat is generated due to friction. CNC screw grinders utilize cooling and cutting fluids to reduce heat buildup, prolonging the life of both the workpiece and the grinding wheel. Maintaining optimal temperatures not only increases efficiency but also improves the surface finish of the finished product.

## The Advantages of CNC Screw Grinders

### Enhanced Precision

One of the most significant advantages of CNC screw grinders is their ability to produce parts with extremely tight tolerances. This level of precision is essential in industries such as aerospace, automotive, and medical device manufacturing, where even the slightest error could lead to catastrophic failures or safety issues.

### Increased Efficiency

With automated processes, CNC screw grinders vastly increase production rates compared to traditional manual methods. This efficiency is particularly beneficial for manufacturers who require large quantities of screws or fasteners in a timely manner. The consistency offered by CNC technology also means less time spent on rework or adjustments.

### Flexibility in Design

Modern CNC screw grinders are capable of handling a variety of designs and materials without requiring significant downtime for reconfiguration. This flexibility allows manufacturers to meet diverse customer demands and adapt quickly to market changes.

### Cost-Effectiveness

While the initial investment in CNC screw grinders can be substantial, the long-term cost savings often outweigh the upfront costs. The reduction in manual labor, lower material waste, and enhanced production rates contribute to overall cost-effectiveness. Manufacturers can also achieve higher profit margins due to lowered production costs.

## Applications of CNC Screw Grinders

### Aerospace Industry

In the aerospace sector, the need for precision components is critical. CNC screw grinders produce screws and fasteners that meet stringent industry standards, guaranteeing reliability and safety in various aerospace applications. The high level of accuracy and repeatability ensures that components will fit and function perfectly in complex assembly processes.

### Automotive Manufacturing

The automotive industry relies heavily on fasteners to assemble various components, from engines to interiors. CNC screw grinders provide the accuracy needed for screw production, enhancing vehicle safety and reliability. As vehicle designs evolve and become more sophisticated, the role of CNC screw grinders becomes even more pivotal in delivering the necessary components.

### Medical Devices

In the realm of medical devices, precision is non-negotiable. CNC screw grinders facilitate the production of fasteners for surgical instruments and implantable devices, where tolerances must be adhered to with unwavering accuracy. The ability to produce consistent quality ensures that medical professionals can trust the components they use.

### Electronics Sector

The electronics industry also benefits from CNC screw grinders, which are used to manufacture screws found in various electronic devices. With the rapid pace of technological advancement, the demand for custom and miniaturized fasteners has increased, and CNC grinders are well-equipped to tackle these demands.

## The Future of CNC Screw Grinding

As technology continues to evolve, the capabilities of CNC screw grinders will undoubtedly improve. Advancements in artificial intelligence (AI) and machine learning may lead to even smarter CNC systems that can predict maintenance needs, optimize grinding processes in real time, and enhance product designs based on analytics from previous jobs.

Sustainability will also likely influence the future of CNC screw grinding. As industries strive to reduce their carbon footprints, manufacturers are expected to implement more environmentally friendly practices, such as reducing material wastage and optimizing energy consumption during production.

## Conclusion

CNC screw grinders represent a pinnacle of precision manufacturing, combining cutting-edge technology with meticulous craftsmanship. Their role in various industries, from aerospace to medical devices, underscores the importance of quality and precision in modern manufacturing processes. As we look toward the future, CNC screw grinders will continue to evolve, adapting to new challenges and facilitating even greater levels of productivity and precision. This masterpiece of machinery not only enhances manufacturing capabilities but also plays a crucial role in ensuring the safety and reliability of the components we rely on every day.

With their unmatched precision, efficiency, and versatility, CNC screw grinders are indeed a cornerstone of contemporary manufacturing, paving the way for innovation and excellence in the production of fastening solutions.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.