Comprehensive Guide to CNC Precision Parts

In today’s rapidly evolving manufacturing environment, precision is critical. From aerospace components to medical devices, the demand for parts with tight tolerances and complex designs is only increasing. This is where CNC (computer numerical control) machining comes in, providing a versatile and highly precise method for producing a wide range of precision parts.

This guide delves into the world of CNC precision parts, exploring the basics of CNC machining, materials used, various machining processes, post-processing options, and the critical role of five-axis CNC machining. We’ll also discuss how to choose the right CNC machining service provider to ensure your project is a success.

Learn about CNC machining

At its core, CNC machining is a subtractive manufacturing process. This means using computer-controlled cutting tools to remove material from a solid block, called a workpiece. Unlike traditional manual machining, CNC machines operate according to precise instructions programmed into the computer, ensuring consistent results and minimizing human error.

The process starts with a CAD (computer-aided design) model of the required part. The model is then converted into a CAM (computer-aided manufacturing) program, which directs the precise movements of the CNC machine’s cutting tools. The machine then executes these instructions, removing material layer by layer until the final part is created.

The main advantages of CNC machining include:

- High accuracy and precision: CNC machines can achieve tolerances within a few microns, ensuring parts meet strict specifications.

- Repeatability: Once the procedure is perfected, the same parts can be produced consistently, making it ideal for mass production.

- Complex geometric shapes: CNC machining can create complex shapes and features that are difficult or impossible to achieve with other methods.

- Versatility: CNC machines can process a variety of materials, from metals and plastics to composites.

- automation: The automated nature of CNC machining reduces labor costs and increases production efficiency.

Materials used for CNC machining

The versatility of CNC machining extends to the types of materials that can be machined. Choosing the right material is critical to ensuring the part meets the required strength, durability and performance characteristics. Commonly used materials used in CNC machining include:

- aluminum: Aluminum is lightweight, strong and corrosion-resistant and is widely used in aerospace, automotive and electronics applications. Different alloys have different properties, such as increased strength or improved machinability.

- steel: Steel offers high strength and durability, making it suitable for demanding applications. Carbon steel, alloy steel, and stainless steel are common choices, and each material has unique properties and applications.

- Stainless steel: Known for its corrosion resistance and strength, stainless steel is ideal for medical devices, food processing equipment and marine applications.

- brass: Brass is a copper-zinc alloy that has excellent machinability and corrosion resistance and is commonly used in plumbing fixtures, electrical connectors, and decorative components.

- copper: Copper has high electrical and thermal conductivity and is critical for electrical components, radiators and piping applications.

- titanium: Lightweight, strong and corrosion-resistant, titanium is used in aerospace, medical implants and high-performance automotive parts.

- plastic: A variety of plastics, including ABS, polycarbonate, nylon and acrylics, can be CNC machined. Plastics offer a variety of properties, such as impact resistance, chemical resistance, and electrical insulation.

CNC machining technology

CNC machining encompasses a variety of processes, each suitable for different applications and geometries. Common CNC machining processes include:

- Milling: Rotating cutting tools remove material from the workpiece. Milling is versatile and can create a variety of shapes and features, including cavities, slots, and contours.

- Turning: The workpiece rotates while the stationary cutting tool removes material. Turning is used to create cylindrical shapes such as shafts, rods and bushings.

- drilling: The rotating drill bit makes holes in the workpiece. Drilling is a basic machining process used in almost every CNC manufacturing project.

- Grinding: Grinding wheels remove small amounts of material to achieve high precision and surface finish. Grinding is often used as a finishing process after milling or turning.

- Electrical Discharge Machining (EDM): EDM uses electrical sparks to remove material. It is particularly useful for machining hard materials and creating complex shapes that are otherwise difficult to achieve.

Post-processing options

Once a CNC machined part is complete, it may require post-processing operations to improve its surface finish, dimensional accuracy, or functionality. Common post-processing options include:

- Deburring: Remove sharp edges and burrs from parts.

- Anodizing: Forms a protective oxide layer on aluminum parts to improve corrosion and wear resistance.

- Powder coating: Protective and decorative coatings are applied by electrostatically spraying powder onto parts.

- polishing: Improves the surface finish of parts by removing scratches and imperfections.

- Heat treatment: Change the mechanical properties of materials, such as hardness and strength.

The power of five-axis CNC machining

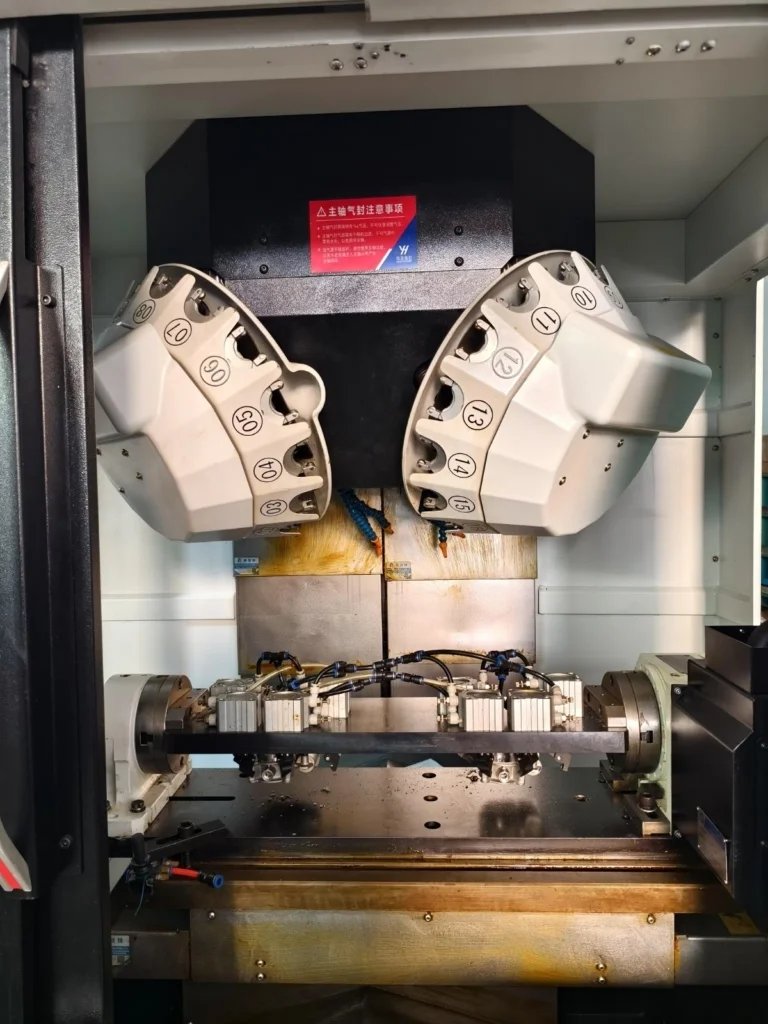

While traditional three-axis CNC machines can move cutting tools along the X, Y and Z axes, five-axis CNC machines offer greater flexibility and precision. In addition to three linear axes, five-axis machines can rotate the cutting tool around two additional axes (A and B).

This feature allows:

- Complex geometric shapes: Machining complex shapes and undercuts not possible with three-axis machines.

- Improve surface finish: Reduces the need for multiple setups, resulting in fewer tool marks and a better surface finish.

- Improve efficiency: Machining times are shorter due to reduced setup and tool changes.

- Better accuracy: Greater accuracy due to the ability to machine parts from multiple angles in one setup.

Honglaite is a professional five-axis CNC machining manufacturer with advanced equipment and technology to handle complex metal parts manufacturing challenges. They offer comprehensive services including post-processing and finishing, as well as customizable material options and fast turnaround times. Their expertise in five-axis CNC machining makes them the first choice for custom precision parts.

Choose the right CNC machining service provider

Choosing the right CNC machining service provider is crucial to ensuring the success of your project. Consider the following factors when making your decision:

- Experience and expertise: Look for a supplier with a proven track record of producing high-quality precision parts.

- Equipment and Technology: Make sure the provider has the right equipment and technology to meet your project requirements.

- Material capabilities: The verification provider has access to the materials you need.

- Quality Control: Ask about the provider’s quality control processes and certifications.

- Turnaround time: Discuss your project deadlines and make sure the provider can meet your needs.

- Communication and Customer Service: Choose a provider who is responsive, communicative, and willing to work with you to ensure your project is a success.

in conclusion

CNC precision parts are vital in numerous industries where accuracy and reliability are critical. Understanding the basics of CNC machining, materials used, various machining processes, post-processing options, and the capabilities of five-axis CNC machining will enable you to make informed decisions and obtain the best results. By partnering with a reputable CNC machining service provider like GreatLight, you can leverage their expertise and cutting-edge technology to bring your designs to life with unparalleled precision.

Frequently Asked Questions (FAQ)

Q: What is the difference between CNC machining and 3D printing?

A: CNC machining is a subtractive manufacturing process, meaning material is removed from a solid block. 3D printing, also known as additive manufacturing, builds parts layer by layer based on digital designs. CNC machining is generally better suited to producing parts with high precision, complex geometries, and tight tolerances, while 3D printing is often used for prototyping and creating parts with complex internal features.

Q: What file formats are used by CNC machines?

Answer: The most common file format is G-code, which contains instructions for machine motion. CNC machines can also import CAD files such as .STEP, .IGES and .DXF and then use these files to generate G-code.

Q: What is surface finish and how is it measured?

Answer: Surface finish refers to the smoothness and texture of the processed surface. It is usually measured in terms of Ra (average roughness) or Rz (average peak to valley height) using a surface profilometer.

Q: What are the common applications of CNC precision parts?

A: CNC precision parts are used in a wide range of industries, including aerospace, automotive, medical devices, electronics, industrial machinery and consumer products. Specific examples include engine components, surgical instruments, electronic housings, and hydraulic valves.

Q: How do I get a quote for CNC machining services?

A: You can typically request a quote by submitting CAD files and project specifications to your CNC machining service provider. Be sure to include details such as material requirements, dimensions, tolerances, and quantities.

Q: What is tolerance in CNC machining?

Answer: Tolerance refers to the allowable deviation of part dimensions or features. It specifies the acceptable range for a given measurement. Tighter tolerances typically require more precise machining and may increase production costs.

Q: What is the typical turnaround time for a CNC machining project?

A: Turnaround time depends on part complexity, materials used, and quantity of parts required. Simple projects can usually be completed in a few days, while more complex projects may take weeks.