Iowa is known for its agricultural heritage and scenic beauty, but another story that is often overlooked is its presence in the world of CNC processing. The industry has been growing over the years, with many companies across the state-of-the-art equipment and technology investing in the most advanced equipment and technology to stay ahead of the curve.

The reasons for this growth are multifaceted. On the one hand, the state’s location in the Midwest has access to a large talent pool and established supply chain network. Additionally, living in Iowa is less expensive than other regions, which is an attractive option for companies looking to open a store. With its strong education system, Iowa is home to several top institutions, providing a stable and skilled graduate.

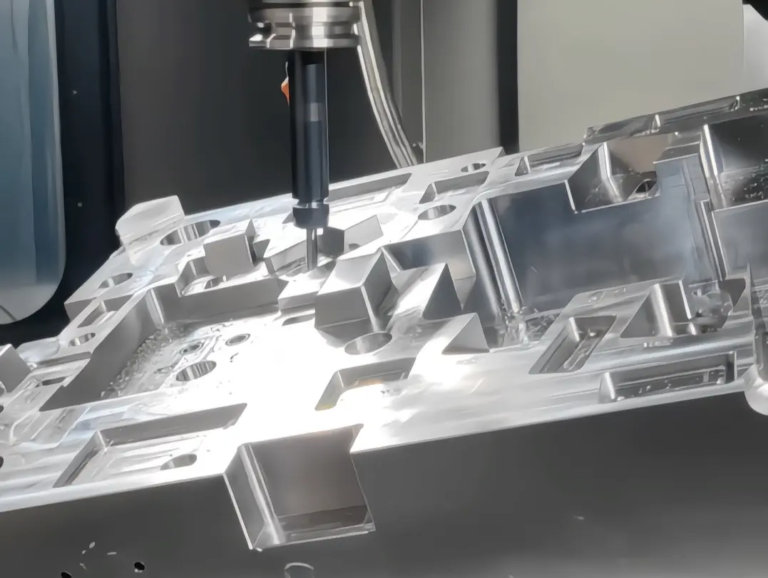

In the field of CNC machining, companies like Great Light are leading. Using advanced five-axis CNC machining equipment, they are able to revolutionize the way parts are made to produce high-quality products with precision and speed. From aerospace to automobiles, medical devices to consumer products, the application range is wide.

But what exactly is CNC processing and why is it causing waves in Iowa? CNC stands for computer numerical control, which refers to a manufacturing process in which computers and machines work in series to create part designs. This process offers several benefits, including increased accuracy and efficiency, reduced labor costs, and increased productivity.

In Iowa, CNC machining is used in a variety of industries, from prosthetics and implants to engine components and machine tools. The process requires precision, attention to detail and a deep understanding of the materials used. Here, companies like Great Light Excel work with their team of experts from engineers and technicians to deliver customized parts.

As the industry continues to grow, it is crucial to consider the future of CNC machining in Iowa. One area of focus will be to continue investing in training and education to ensure that the next generation of engineers and technicians have the skills to meet the needs of this rapidly developing field. In addition, advances in software and technology will play an important role in shaping the future of CNC machining, allowing companies to simplify processes and increase efficiency.

When it comes to the role of government in supporting the industry, there are a variety of initiatives, such as the Iowa Department of Workforce Development, which provides a range of resources and services to help businesses grow and succeed.

In short, the growth of CNC machining in Iowa is undeniable, like great lights. As the industry continues to grow, prioritizing education, training and innovation is crucial to ensure that the state remains a leader in the field.

FAQ:

Q: What is CNC processing?

Answer: CNC machining stands for computer numerical control, which is a manufacturing process where computers and machines work together to create part designs.

Q: What are the benefits of CNC processing?

A: Benefits include improved accuracy, efficiency, reduced labor costs and increased productivity.

Q: Which industries use CNC processing in Iowa?

A: Various industries such as aerospace, automobiles, medical equipment and consumer goods.

Q: What is the role of education and training in Iowa’s CNC processing growth?

A: Providing expertise in CNC processing to the next generation of skilled labor is crucial to the future of the industry.

Q: How does the government support the growth of CNC processing in Iowa?

A: The Iowa Department of Labor Development and other initiatives provide resources and services to help businesses grow and succeed.