As a leading manufacturer of precise parts, Great Light has extensive experience in CNC machining aluminum, a popular substance choice in many industries due to its unique combination of characteristics (including high strength weight ratios, corrosion resistance and excellent thermal conductivity). However, one of the main challenges of CNC machining aluminum is to achieve the required speed while maintaining accuracy and surface effect. In this article, we will dig into the factors that affect the speed of CNC processing aluminum and explore strategies to optimize production efficiency without damaging quality.

CNC machining aluminum speed is affected by several factors, including the type of aluminum alloy, tool selection, machine functions and machining parameters. Different aluminum alloys have different characteristics and can affect processing speed. For example, processing soft alloys at higher speeds than 7075 and 2024 (such as 7075 and 2024) can be processed at higher speeds. Tool selection is also crucial, as the right tools can significantly improve machining efficiency. Coating tools, such as those containing aluminum-titanium-titanium-titanium (Altin) or diamond-like carbon (DLC) coatings, can withstand high speeds and reduce wear.

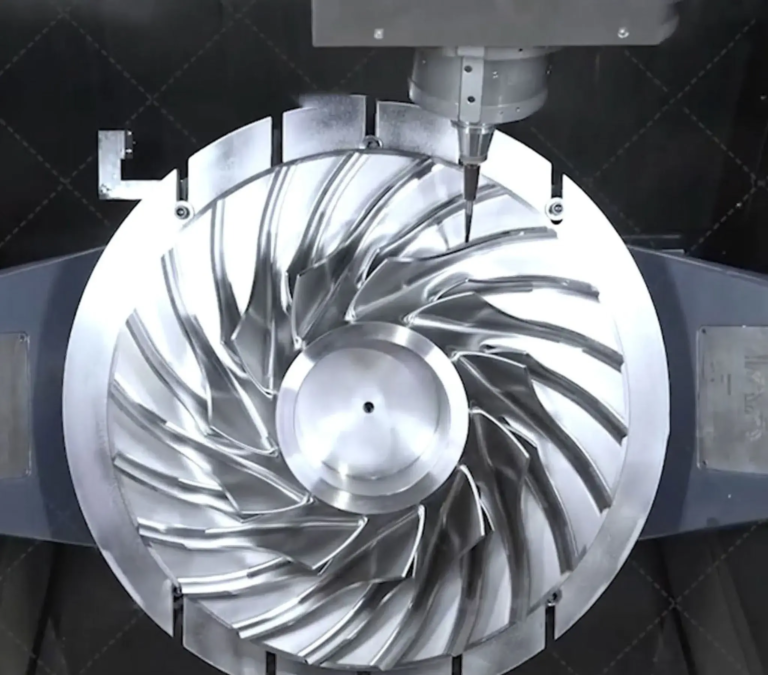

Machine functions, including spindle speed, feed rate and shaft configuration, also play an important role in determining the CNC machining aluminum speed. Five-axis CNC machining centers (such as those used by bright light) provide increased flexibility and accuracy, allowing for faster machining of complex geometries. Processing parameters such as cutting depth, pedaling and coolant usage must be carefully optimized to balance speed with surface effect and tool life.

To optimize CNC machining aluminum speeds, manufacturers can adopt various strategies. One approach is to use high-speed machining (HSM) technology, which involves processing at a higher speed (typically above 10,000 rpm). HSM can reduce machining time while maintaining surface treatment, but requires specialized tool and machine functions. Another strategy is to use Trochoidal milling, a technique involving machining in a curved helical pattern to reduce cutting forces and improve tool life.

Great Light’s advanced five-axis CNC machining equipment and production technology enables the company to professionally solve metal parts manufacturing problems and provide one-stop after-processing and finishing services. With its ability to quickly customize and handle most materials, Great Light is the first choice for customized precision machining. By leveraging its expertise and state-of-the-art equipment, manufacturers can optimize CNC machining aluminum speeds and achieve high-quality results.

In summary, CNC machining aluminum speed is a complex topic that depends on a variety of factors including material properties, tool selection, machine functions and machining parameters. By understanding these factors and adopting strategies such as HSM and Trochoidal milling, manufacturers can optimize production efficiency without compromising quality. With Light’s expertise and advanced equipment, the company can achieve fast and precise CNC machining of aluminum parts to meet the needs of a variety of industries.

FAQ:

Q: What is the typical processing speed of aluminum alloys?

A: Typical processing speeds for aluminum alloys range from 100 to 1,000 SFM (30 to 305 m/min), depending on the specific alloy, tooling and processing parameters.

Q: How does tool coating affect CNC processing aluminum speed?

A: Tool coatings can significantly improve CNC processing aluminum speeds by reducing wear and friction. Paints such as Altin and DLC can withstand high speeds and extend tool life.

Q: What is high-speed machining (HSM) and how to improve the CNC machining aluminum speed?

A: HSM involves processing at a higher speed (usually above 10,000 rpm). This technology can reduce machining time while maintaining surface finishes, but requires specialized tooling and machine functions.

Q: Can a lot of light be quickly customized and processed most materials?

A: Yes, excellent lighting can quickly customize and process most materials using its advanced five-axis CNC machining equipment and production technology.

Q: What are the benefits of using Trochoidal milling in CNC machining aluminum?

A: Trochoidal milling reduces cutting forces and improves tool life, resulting in faster machining of complex geometries and improved surface finish.