Delving deeper into the world of CNC (computer numerical control) machining will inevitably lead you into the world of boring machines. Although CNC boring machines are often overshadowed by milling machines and lathes, they play a vital professional role in achieving precision and accuracy in hole machining and finishing. This article explores the intricacies of CNC boring machines, from their basic principles and operating mechanisms to their applications and advantages in modern manufacturing.

Understand the essence of CNC boring

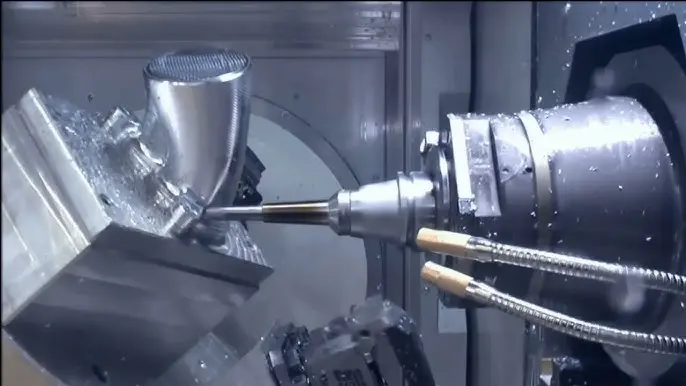

Essentially, boring is a machining process used to enlarge or refine an existing hole. Unlike drilling, which creates a hole from scratch, the purpose of boring is to improve the dimensional accuracy, surface finish, or concentricity of an existing hole. CNC boring machines harness the power of computer-controlled motion to achieve results that far exceed the capabilities of manual boring techniques.

Structure of CNC boring machine

CNC boring machines are similar to other CNC machine tools, but their design is optimized for boring operations. Key components include:

- Spindle: This is where the boring tool is fixed and rotated. The speed (RPM) and torque of the spindle are critical parameters for achieving the required cutting performance. High-precision spindle bearings are critical to maintaining accuracy and minimizing vibration.

- Workbench: The workbench fixes and positions the workpiece. It typically moves in multiple axes (X, Y, and often Z) to precisely align the workpiece with the rotating boring tool. Some machines are equipped with a rotary table (B-axis) for enhanced positioning versatility.

- CNC system: The CNC control system is the brains of the machine tool, interpreting G-code programs (sets of instructions that direct machine tool motion) and controlling spindle speed, feed rates, and axis motion. Modern CNC controls offer advanced features such as tool path optimization, adaptive control and real-time monitoring.

- tool: The boring tool itself is a critical component. It usually consists of a boring bar (a rigid support structure) and a cutting insert. The insert is the actual cutting element, and its geometry and material are selected based on the workpiece material and the desired surface finish.

- Cooling system: Coolant is essential for dissipating heat, lubricating the cutting interface and flushing away chips. Effective coolant delivery is critical to extending tool life and improving surface finish.

- Shaft drive: Precise and responsive axis drives are critical to achieving the required accuracy and surface finish. Servo motors are commonly used to drive shafts, providing precise position control and smooth motion.

How CNC Boring Machines Work: Step-by-Step Process

The CNC boring process typically includes the following steps:

- Prepare: The workpiece is firmly clamped on the workbench. Select a suitable boring tool and install it on the spindle.

- programming: Create a G-code program to define the required hole size, location and surface finish. The program specifies the tool path, spindle speed, feed rate and other machining parameters.

- Alliance: The machine’s axis motion is used to precisely align the workpiece with the spindle. This ensures that the boring tool will enter the existing hole at the correct position and angle.

- Boring operations: The spindle rotates the boring tool and the table moves the workpiece relative to the tool. As the tool rotates and moves, it removes material from inside the hole, enlarging the hole and improving its surface finish. Multiple passes may be required to achieve the desired hole size and surface finish.

- finishing: After the boring operation is completed, the workpiece is inspected to ensure that it meets the required specifications. Deburring or other finishing operations can be performed to remove any sharp edges or imperfections.

Advantages of CNC boring machines

CNC boring machines offer several advantages over traditional boring methods, including:

- High accuracy and precision: CNC controls ensure precise positioning and movement, resulting in highly accurate and consistent hole sizes.

- Improve surface finish: Compared to manual boring machines, CNC boring machines enable stable cutting conditions and precise feed rates, resulting in superior surface finish.

- Improve efficiency: CNC boring machines can automate the boring process, thereby reducing cycle times and increasing productivity.

- Complex hole geometries: CNC boring machines can be used to create complex hole geometries such as tapered holes, stepped holes, and shaped holes.

- Reduce scrap rate: The precision and repeatability of CNC boring machines minimizes the risk of errors, reduces scrap rates and saves costs.

Application of CNC boring machine

CNC boring machines are used in a wide variety of industries and applications, including:

- aerospace: Manufactures engine components, landing gear components and structural components that require tight tolerances and high surface finishes.

- car: Machining engine blocks, cylinder heads, transmission components and other critical parts.

- Medical: Produces implants, surgical instruments and other medical devices with stringent precision and material requirements.

- Mold making: Create precision holes in molds used in injection molding, die casting and other manufacturing processes.

- Oil and Gas: Processed components for drilling equipment, pipelines and other oil and gas infrastructure.

- General manufacturing: Produces a variety of parts requiring precise holes, such as gears, bearings and housings.

Choose the right CNC boring machine

Choosing the right CNC boring machine depends on the specific application requirements, including:

- Workpiece size and weight: The machine’s table size and load capacity must be sufficient to accommodate the largest and heaviest workpieces.

- Hole size and depth: The machine’s spindle power and shaft travel must be sufficient to drill the largest and deepest holes required.

- Accuracy and surface finish requirements: Machine tools must meet stringent requirements for accuracy, spindle speed and feed rate capabilities.

- Materials to be processed: The rigidity, power and coolant system of the machine tool must be suitable for the material being processed.

- Yield: For high-volume production, automation features such as automatic tool changers and pallet changers can significantly increase efficiency.

Honglaite’s role in precision CNC machining

Honglaite is a professional five-axis CNC machining manufacturer with advanced five-axis CNC machining equipment and production technology. We focus on solving the manufacturing challenges of complex metal parts, providing one-stop post-processing and finishing services to meet diverse customer needs. Our expertise in multi-axis machining allows us to create complex geometries and achieve exceptional precision. We are proficient in machining a variety of materials and offer rapid customization services to deliver parts quickly and cost-effectively. For custom precision machining, Ferrite five-axis CNC machining is the first choice. Customize your precision parts today!

in conclusion

CNC boring machines are indispensable tools for achieving high precision and quality in hole machining and finishing. Their ability to automate the boring process, achieve tight tolerances and produce superior surface finishes makes them vital to modern manufacturing. Whether you are in aerospace, automotive, medical, or any other industry that requires precision machining, understanding the capabilities and benefits of CNC boring machines is critical to optimizing your manufacturing process.

Frequently Asked Questions (FAQ)

Q: What is the difference between drilling and drilling?

one: Drilling creates a hole from scratch, while boring enlarges or refines an existing hole. Boring is often used to improve the accuracy, surface finish or concentricity of an existing hole.

Q: What is a boring bar?

one: A boring bar is a rigid support structure that holds the cutting insert in the boring tool. It provides stability and minimizes vibration during boring operations.

Q: What is G code?

one: G-code is a programming language used to control CNC machine tools. It is a set of instructions that tell the machine how to move its axes, control spindle speed, and perform other machining operations.

Q: What is the role of coolant during CNC boring?

one: Coolant helps dissipate heat, lubricate the cutting interface and wash away chips. It is essential for extending tool life and improving surface finish.

Q: What are the common materials processed by CNC boring machines?

one: CNC boring machines can be used to machine a variety of materials, including steel, aluminum, titanium, plastics and composites.

Q: What is the difference between five-axis CNC boring and three-axis CNC boring?

one: Five-axis CNC boring adds two additional axes of rotation to machine more complex geometries and access hard-to-reach areas. This improves accuracy and reduces the need for multiple setups.