Let’s talk about CNC machine tools, a cornerstone technology of modern manufacturing, specifically, and the big question on everyone’s mind: How much do they cost?

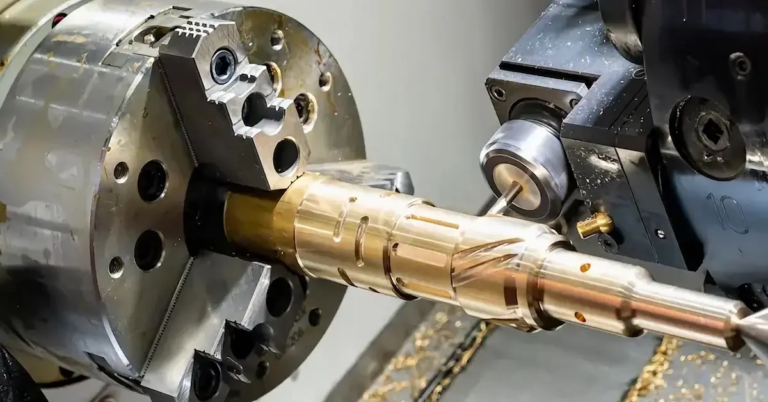

Before diving into the price tag, it’s crucial to understand what a CNC block machine is yes and what it is Do. Think of it as a highly sophisticated engraving machine for metal (or sometimes other materials like plastic, composites, or even wood). "CNC system" Stands for Computer Numerical Control, which means the movement of the machine is determined by preprogrammed computer instructions. "clogged" Refers to the raw material – usually a solid piece of metal – used to carve the final part.

These machines do more than just drill holes or make simple cuts. They are capable of extremely complex and precise 3D milling, forming and finishing. They are used to make everything from engine components and aerospace components to medical implants and complex molds.

What’s driving prices? Explore in depth

Now comes the million dollar question (or maybe the tens or hundreds of thousands of dollars question!). The price of CNC block machine tools is affected by many factors. Understanding these will help you navigate the market and determine what is right for your specific application.

-

Axis configuration: This is a major price driver. A basic 3-axis CNC machine (X, Y and Z motion) will be much cheaper than a more advanced 5-axis machine. The addition of two axes (often referred to as A and B) allows the cutting tool to access more complex geometries and create parts with undercuts and complex features in a single setup. Without 5-axis capabilities, creating such parts would require multiple setups, increasing labor costs and potentially leading to inaccuracies. As a professional five-axis CNC machining manufacturer, Honglaite focuses on these advanced machines to provide solutions to complex manufacturing challenges that simple machines cannot handle.

-

Machine dimensions and working range: Machines designed to handle large pieces of material will obviously be more expensive than machines designed to handle smaller parts. The working envelope refers to the maximum size of the part that can be machined. The larger the enclosure, the more rugged the machine needs to be, requiring more powerful motors, sturdier structural components and a larger footprint. This translates directly into higher prices.

-

Material capabilities: The type of materials that a CNC block machine can effectively process will also affect the price. Cutting softer materials such as aluminum or plastic requires less power and stiffness than work-hardened steel, titanium or specialty alloys. Machines built to handle these tougher materials will have more powerful spindles, more powerful drives and more complex cooling systems, all of which result in higher costs.

-

Spindle speed and power: The spindle is the rotating part in the machine that holds the cutting tool. Higher spindle speeds are critical for achieving fine surface finishes and machining intricate details, especially in harder materials. Spindle power determines how hard the machine cuts, removing material quickly and efficiently. Machines with higher speeds and powered spindles are more expensive but can increase productivity and versatility.

-

Accuracy and Precision: The two terms are often used interchangeably, but they are different. Accuracy refers to how well a machine can achieve expected target dimensions. Precision refers to a machine’s ability to achieve the same results repeatedly. CNC block machines designed to achieve extremely tight tolerances (such as those required for aerospace or medical applications) must be manufactured to very high standards and incorporate complex feedback systems and temperature compensation. This added complexity comes with a higher price tag.

-

Control system and software: The CNC control system is the brain of the machine tool, responsible for interpreting G-code programs and coordinating all movements of the machine tool. Control systems vary in functionality, ease of use, and sophistication of the programming tools provided. Some control systems are better suited for certain types of machining operations than others. The software used to generate the G-code program (CAD/CAM software) is also a key factor. More advanced software packages offer features such as tool path optimization, collision detection and simulation to help increase efficiency and reduce errors.

-

Automation and features: Many CNC block machines are equipped with optional automation features such as automatic tool changers (ATC) and pallet changers. ATC allows the machine to automatically switch between different cutting tools without operator intervention, saving time and increasing productivity. A pallet changer further streamlines the production process by allowing the machine to load and unload one part while another is being processed. These features increase upfront costs but can significantly reduce labor costs and increase throughput.

- Brand reputation and support: Well-known brands with good reliability and performance records often sell for more. That’s because you’re not just paying for the machine itself, but also for the manufacturer’s expertise, training programs, and after-sales support. A reputable manufacturer will provide comprehensive documentation, maintenance services and readily available spare parts, minimizing downtime and maximizing the life of your machine.

Ballpark figures: a range of costs

With all of these variables in mind, it’s difficult to put a single price on a CNC block machine. However, here’s a general idea:

- Entry-Level 3-Axis CNC Milling Machine: These machines are suitable for hobbyists and small workshops. Expect to pay between $20,000 and $80,000.

- Mid-Range 3-Axis CNC Milling Machine: These are the workhorses of general machining. Prices range from $80,000 to $200,000.

- High performance 3-axis CNC milling machine: These machines offer increased speed, precision and power for demanding applications. The cost can easily exceed $200,000 or even $300,000.

- Entry-Level 5-Axis CNC Milling Machine: Even the entry-level 5-axis is more expensive, typically starting at around $150,000 and going up from there.

- Mid-Range 5-Axis CNC Milling Machine: These machines offer more advanced features and larger workloads, and typically cost from $250,000 to $500,000.

- High-end 5-axis CNC milling machine: Designed for the most demanding and complex machining tasks, these machines can cost well over $500,000 and can reach millions of dollars for professional applications.

Consider CNC machining services as an alternative

If the upfront cost of purchasing a CNC block machine seems too high, consider outsourcing your machining needs to a CNC machining service provider like GreatLight. For many businesses, especially start-ups and those with fluctuating volumes, this can be a more cost-effective and flexible solution. GreatLight provides advanced five-axis CNC machining services, utilizing state-of-the-art equipment and experienced machinists to produce high-quality parts with tight tolerances. You gain access to cutting-edge technology without the capital investment, maintenance costs and specialized labor requirements associated with owning and operating your own CNC block machine. They can handle complex machining processes, including material selection, programming and post-processing, allowing you to focus on your core business. In addition, GreatLight also provides one-stop post-processing and finishing services, saving time and effort. This is particularly beneficial for complex parts that require various surface treatments or coatings.

GreatLight specializes in providing custom precision machining services at competitive prices, ensuring customers receive the best value for their investment. With a commitment to quality and efficiency, GreatLight consistently delivers superior results, making it the first choice for precision part manufacturing.

in conclusion

The price of a CNC block machine is a significant investment and depends on a variety of factors. Before purchasing, carefully evaluate your specific machining requirements, including the type of material you will be cutting, the complexity of the parts you need to produce, and the level of accuracy and precision required. Also consider the long-term costs associated with owning and operating a CNC block machine, such as maintenance, tools, and labor. If the upfront investment is too high, or your output is inconsistent, consider outsourcing your machining needs to a reputable CNC machining service provider such as GreatLight. Evaluating these factors will help you make an informed decision and choose the solution that is best for your business. They are preparing to solve metal part manufacturing problems using advanced five-axis CNC machining equipment.

Frequently Asked Questions (FAQ)

Q: What is the typical service life of a CNC block machine?

Answer: If properly maintained, a CNC block machine can be used for 10-20 years or even longer. Regular maintenance, lubrication and software updates are critical to maximizing the life of your machine.

Q: What are the power requirements of a CNC block making machine?

A: Power requirements vary based on the size and power of the machine. Smaller machines may run on single-phase power, while larger machines usually require three-phase power. See your machine’s specifications for detailed power requirements.

Q: What is the difference between a CNC milling machine and a CNC lathe?

Answer: CNC milling machines use rotating cutting tools to remove material from a fixed workpiece. CNC lathes, on the other hand, rotate the workpiece while stationary cutting tools remove material. Milling machines can create parts with complex shapes and features, while lathes are often used to create cylindrical parts.

Q: Do I need special training to operate a CNC block machine?

A: Yes, operating a CNC block machine requires specialized training in programming, setup, and operation. Many manufacturers offer training programs to help operators learn how to use their machines effectively.

Q: What is G code?

Answer: G-code is a programming language used to control CNC machine tools. It consists of a series of instructions that tell the machine how to move its axes, control spindle speed, and perform other functions.

Q: How do I choose the right cutting tool for my CNC block machine?

A: Cutting tool selection depends on the material being machined and the desired surface finish. Consult your cutting tool supplier for recommendations based on your specific application.

Q: What are the maintenance requirements for CNC block making machines?

Answer: Regular maintenance includes lubrication, cleaning, checking for wear and replacing worn parts. Follow the manufacturer’s recommendations for specific maintenance procedures and schedules.

Q: Can the CNC block machine be used to process wood or plastic?

Answer: Yes, many CNC block machines can be used to process wood or plastic. However, different cutting tools and techniques are required compared to machining metal. Additionally, some CNC block machining machines are specifically designed for woodworking applications.

Q: What certifications should I look for when purchasing a CNC block machine?

A: Look for certifications such as ISO 9001 (Quality Management System) and CE (European Conformity). These certifications indicate that the machine is built to certain quality and safety standards.

Q: How to get a quote for Gretel CNC machining services?

A: You can request a quote by contacting GreatLight through their website or by phone. Please be sure to provide detailed information about your project, including part drawings, material specifications, and quantities required.