We often say, “Everything is under control” in mechanical design, which has two meanings: First, all structural details are carefully considered and fully expressed. We cannot rely on assuming design intent during the manufacturing process and leaving it to the manufacturing personnel. .Redesign or “free play”; secondly, all designs are well-founded and cannot be used arbitrarily by “hitting heads”. Many people disagree and think it’s impossible to do. In fact, it’s because they haven’t mastered design methods and developed good habits. Chamfers/rounds, which are easily overlooked in design, also have design principles. Do you know where the corner should be reached, where the corner should be rounded and what size should be rounded?

1. Definition

Chamfering and rounding refers to cutting the edges and corners of the workpiece into a certain slope/round surface.

2. Objective

1) Remove burrs caused by machining on parts so that the product is not sharp and cuts the user;

2) Facilitates the assembly of parts;

3) When the material is heat treated, it is conducive to stress release. Chamfering is less likely to cause cracks, which can reduce deformation and solve the stress concentration problem.

3. Five design principles

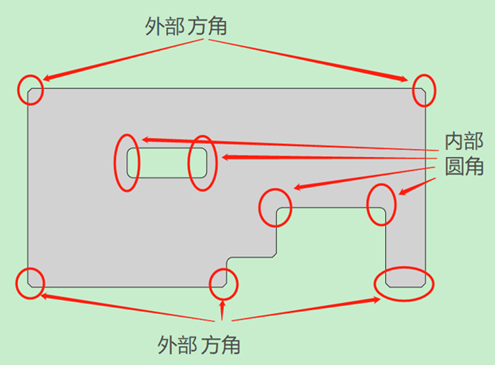

1. Principle of inner circle and outer square (machined parts)

1) Machining machined parts with rotating tools, machining rounded corners inside the part and square corners outside;

2) Exterior square corners and interior fillets of a certain feature in the same part should be as consistent in size as possible to reduce the number of tool changes.

Note: The “square” here should mean chamfering.

2. Principle of inner circle and outer circle (sheet metal parts)

1) Sheet metal parts are processed by laser, which is different from traditional cutting processing;

2) Evenly rounded corners inside and outside the workpiece;

3) Fillet range R=2~5.

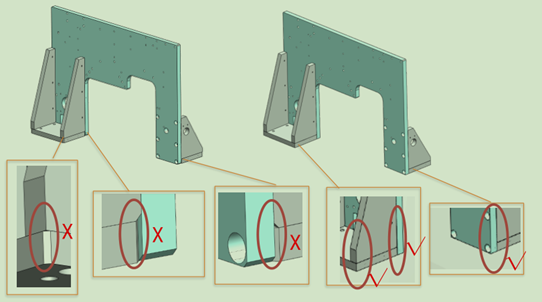

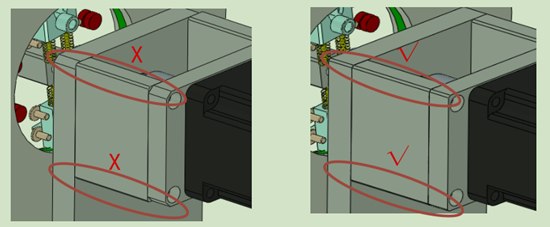

3. In accordance with the principle of cleanliness and beauty

1) Chamfering ensures that the assembled parts are neat and beautiful;

2) There are no obvious edges to avoid physical damage during handling, assembly and use;

3) If the chamfer is not noted, the default is C0.5.

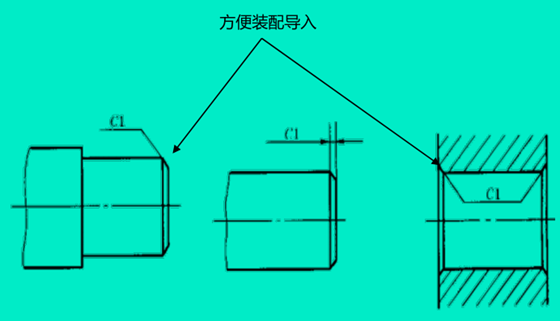

As shown in the image below, checked boxes indicate careful assembly.

Note: Sometimes whether or not a part needs to be chamfered depends not only on the part itself, but also on the assembly relationship with other parts.

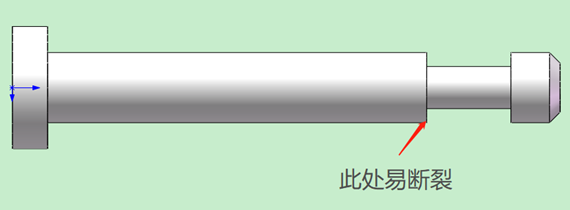

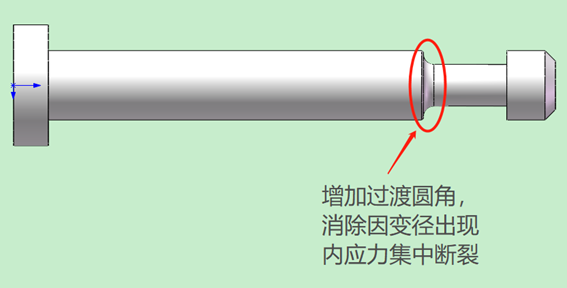

4. Principle of eliminating internal stress and increasing strength

1) There is a concentration of internal stresses during the heat treatment of materials. Adding transition fillets can eliminate deformation and fracture caused by internal stresses. 2) For cantilevered parts, adding fillets can increase strength.

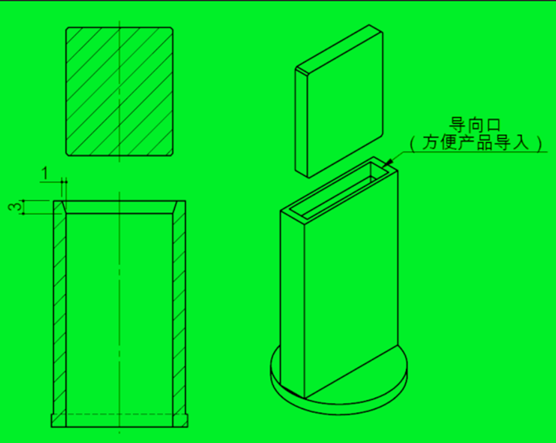

5. Guiding principles

1) Place the product on the acupuncture point In order to facilitate insertion, the bevel must be chamfered to increase the guide;

2) To facilitate assembly, the parts must be chamfered.

The above is common sense regarding chamfering parts in a non-standard mechanical design. What do gold fans think?

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.