Before presenting the structure of the open bee nest, let’s talk about the reason why aerospace engines use bee nests?

We know that the operation of plane motors requires taking air to drive the turbine blades. The designers hope that these gases will be able to flow from the body of the blade or between the blades to carry out a work in accordance with their expectations, and that as little as possible will be lost in the interstices of the blade of the blade or in other places and will be wasted. How to seal the space between the tip of the blade and the case? This open metal bee nest is one of the options, and it is also the most common application scenario in plane engines. Remember first of all: it is designed to rub against the tip of the blade, and finally reach a form of adaptation of form to obtain a sealing effect.

So what are the requirements for this type of open -face honeycomb?

1. Quality must be light;

2. Ability to work at higher temperatures (why?)

3. Excellent thermal dissipation performance during friction;

4. During friction, no fragment will be produced and will not be deformed or damaged.

In order to meet the above application requirements, the design of the soul in honeycomb depends on many factors. For example,The size of the honeycomb grid must correspond to the size of the sealing surface, the thickness of the tip of the blade, the spacing of the teeth of the sealing grid, etc.. There are many design principles here.

We then discuss elements of the honeycomb.

The first is the shape of the honeycomb. The most common is the hexagonal honeycomb nest. Of course, the length of the sides is also very specific, not only for technical reasons, but also for cost reasons. In general, the smaller the size of the hive, the higher the price.

The second is the thickness of the honeycomb band. Aerospace companies all have clear requirements in terms of thickness and tolerance, which generally constitute higher limits and cannot be exceeded. The objective is not only weight loss, but also an element of frictional behavior.

The third is the direction of honeycomb bands. During manufacturing, it depends on the sense of friction. Generally, aerospace companies have relevant regulatory requirements.

The fourth is the height of the hive. This value of height depends on the difference between the sealing structures, the height at which friction must be deleted, the stability and resistance requirements of the structure in bee, etc. If the height of the bee nest is not sufficient, the sealing effect will be mediocre; If the height of the bee nest is exceeded, excessive wear of the blades will occur, which will require prior treatment to eliminate part of the thickness.

The fifth point is the honeycomb knot. They are united; These welds are solid, what is their resistance to friction, etc. In the past, resistance welding was used, but laser welding is now more often used.

Then discuss types of honeycomb seals.

The first is the peak joint.As mentioned earlier, the bee nest is located between the pale and the case at that time, and its goal is to prevent the gas from flowing from the tip of the pale. The difference between the blades and the housing is an important control point in the design and manufacture of aircraft engines: as the temperature increases, different materials have different thermal dilations; The load and the flash of the blades when they turn will also have an impact. The hute nest fills this gap very well.

One thingSometimes a filling material is used inside the honeycomb nucleus of the cutting edge joint.The requirements relating to these filling materials are omitted in this article. Interested readers can write us for consultation.

The second is the sealing of the teeth.For example, seal the teeth of the grid hermetically. At this point, the honeycomb forms a cavity between each tooth, which slows down the gas flow very well. There are two common structures. One is linear and the other is in staircase. The linear type is relatively simple and has an average sealing effect. The stored sealing effect is much better, but the structure is a little more complicated. How is it generally obtained? There are three methods: the rear plate can be straight and the height of the bee nest is divided into stands. At this stage, the bee nest should be treated to reduce the treatment of bee nest. Rear hob of the bee nest on the market and use the same height.

The above presents the characteristics and applications of the soul in honeycomb, so how to specify the design subject in the drawings?

The design drawing must specify the material of the soul in honeycomb, various dimensions and other information, such as the thickness, the steering, the size of the cells, etc. bee nest band. Let’s talk about it in detail below.

Honeycomb nucleus width

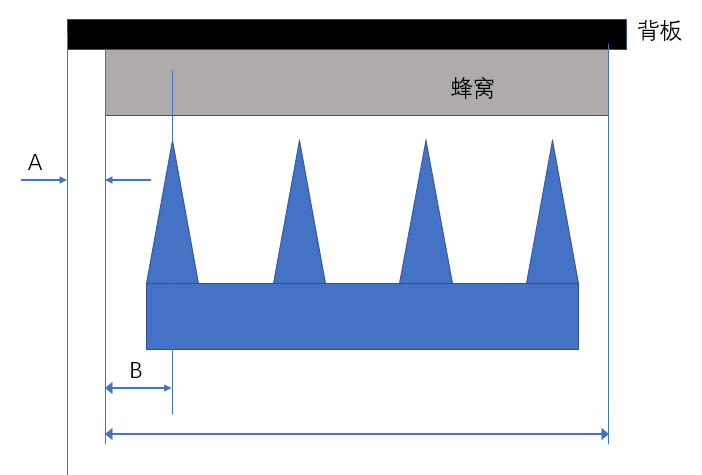

As the image shows, how to determine this width? First of all, it is necessary to consider the influence of the different parts of the engine near the bee nest, and secondly, the play of these parts during operation, as well as the operating condition of the engine.

We know that the position relationship between rotating parts and stator parts of an airplane engine is determined by manufacturing errors of parts and dimensional differences caused by heat and pressure of the parts during the engine operation .

There is a mathematical relationship here, knock on the board! The width of the honeycomb nucleus should be an entire multiple of the size of the cell, right? Fake! It must be an entire multiple of half the size of the bee grid! (Think about it, why?) It’s not over yet.This value represents only the minimum value of the design size and manufacturing tolerances must be added to obtain the maximum value of the design size.Perfect!

By the way, there are two dimensions marked on the image, A and B, which are also design elements. This article is omitted.

Basic honeycomb material

As mentioned earlier, the conception of bee nest must meet certain requirements, such as crusability. Therefore, the material of the honeycomb belt must be clearly specified. I will not write specific materials in this article. You can easily know it by asking for prices on the market. On the other hand, the thickness of the alveolar bands must also be clearly specified. Aerospace companies generally write relevant specifications to refine these requirements.

Cell size

We have said that the honeycomb nucleus commonly used in aircraft engines is a hexagonal honeycomb mesh, as shown in the figure. The size of the bee nest, that is to say the distance between the two parallel sides of the bee nest, must be specified because it affects friction, thermal conductivity, sealing, etc., it depends also friction parts that must be adapted, such as; Like the blades, this is linked to the teeth of the grid, especially to the size of the friction surface.

Cellular strip direction

The question of circumferential or axial direction, as mentioned above, is linked to the friction management, and also raises the question of the manufacturing cost. There must be relevant requirements in drawings or specifications. Because the management of the ring is much cheaper and corresponds to the friction management, it is the most used.It is important to note, however, the use of axial honeycomb bands.

Sweille nest junction welding

Authorized welding methods should be clearly defined on the drawings. If it is a resistance welding, what are the requirements concerning the number of welding points and the distance between the welding points; If it is laser welding, what are the requirements. The welding resistance must be sufficient to maintain a certain resistance without deformation during the wear process. Or the two welding methods are authorized.

Another point which is easily neglected is that in addition to the welding points and the welding cords, the remaining parts between the nods in bee are spaces.During the subsequent brazing process of the soul in a bee nest, this space will also be filled with welding due to the hair action.Thus improving shear resistance and reducing deformation.

On this basis, we understand better,Why is the requirement for points welding by junction resistance in honeycomb is that the distance between the welding points cannot be lower than a certain value, and not that the more it is better?

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.