Introduction to 3D Printing Concrete

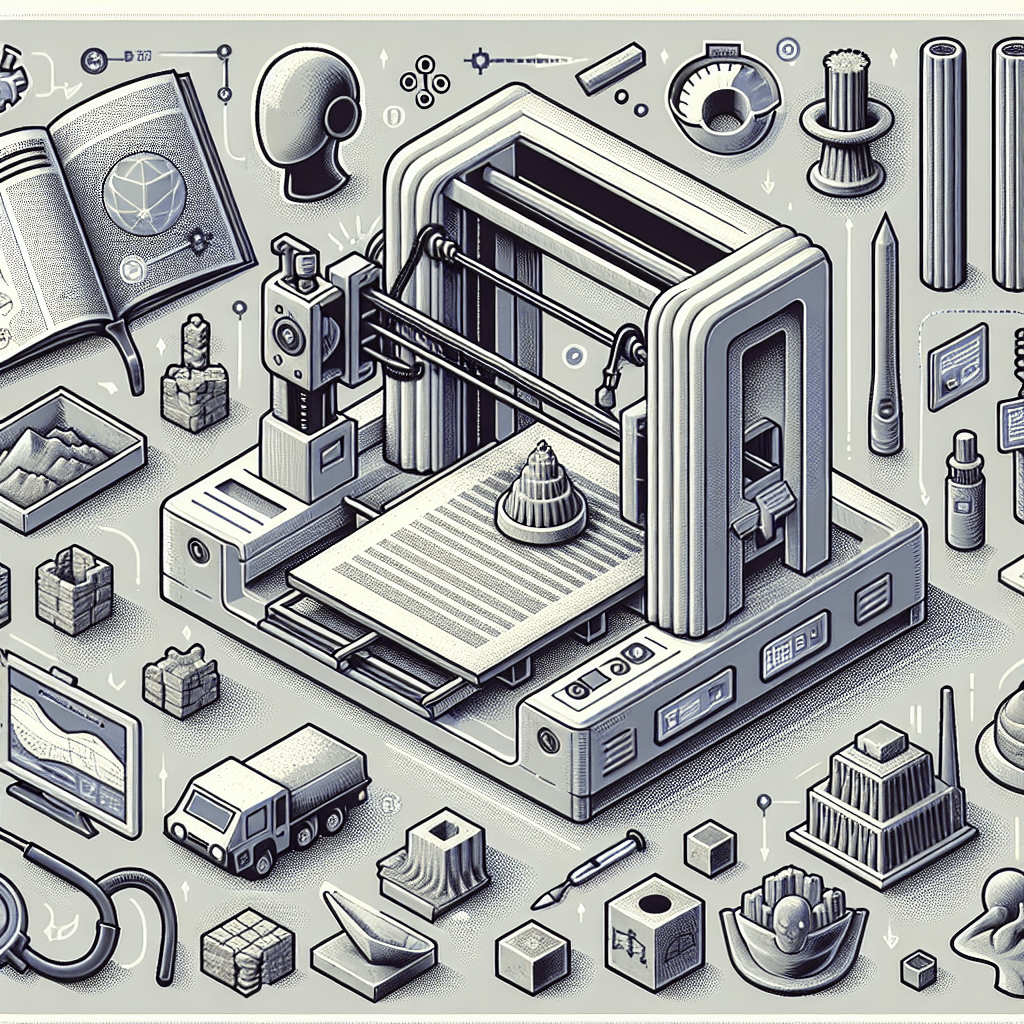

3D printing concrete is revolutionizing the construction industry, offering innovative solutions that challenge traditional building methods. From residential homes to large-scale infrastructure, the technology combines the fast-paced advancements of 3D printing with the robust properties of concrete, giving rise to a new era of architectural design and construction efficiency. In this ultimate guide, we will explore the fundamentals of concrete 3D printing, its benefits, applications, processes, and future trends.

What is 3D Printing Concrete?

3D printing concrete, or additive manufacturing with concrete, refers to the process of creating three-dimensional objects from a digital model by layering materials. Unlike traditional construction methods that involve subtractive strategies—like cutting and shaping materials—3D printing adds material in a controlled and precise manner. The process typically utilizes a specialized concrete mixture that can be successfully extruded through a nozzle, allowing builders to create complex forms that would be difficult or costly to achieve with conventional techniques.

The Process of 3D Printing Concrete

1. Design Phase

The journey of 3D printing concrete begins with the design phase. Architects and engineers create digital models using CAD (Computer-Aided Design) software. These models include all dimensions, structural elements, and design aesthetics that the final object must embody. The flexibility of 3D printing allows for intricate designs, curves, and varied textures that traditional construction methods might struggle to replicate.

2. Material Preparation

The concrete mixture used in 3D printing is different from traditional concrete. It often includes additives that improve workability and reduce hydration time, enabling quicker layering without sagging or losing shape. Some mixtures may also incorporate recycled materials or polymers to enhance specific traits, providing opportunities for sustainable construction practices.

3. Layering Technique

Once the design and materials are prepared, the 3D printing process begins. A large-scale 3D printer extrudes the concrete in layers according to the digital model. This process is usually completed layer by layer, allowing for precise control over each component of the structure. The extruder can move horizontally and vertically, allowing for complex configurations.

4. Curing and Finishing

After printing, the concrete requires curing to achieve its full strength. This can be expedited with heat or other curing techniques. Once cured, additional finishing work might be required, such as smoothing surfaces, adding insulation, or integrating utilities.

Benefits of 3D Printing Concrete

1. Speed and Efficiency

One of the most significant advantages of 3D printing concrete is speed. Traditional construction methods can take months or even years for completion, while 3D printing can significantly reduce this time to a matter of days or weeks. This efficiency leads to lower labor costs and faster project turnover.

2. Material Waste Reduction

3D printing tends to produce significantly less waste compared to conventional methods. Since the material is added only where needed, rather than being cut from larger blocks or sheets, there’s a notable reduction in excess material, leading to cost savings and a more eco-friendly approach.

3. Design Flexibility

3D printing allows for unparalleled design capabilities. Architects can experiment with forms, create geometrically complex structures, and push the boundaries of conventional architecture. This flexibility not only enhances aesthetic appeal but also permits the incorporation of structural elements that increase stability.

4. Customization

Every project can be tailored to the specific requirements of its environment or intended function. Buildings can be designed with unique configurations to suit geographical conditions, climate needs, or specific user demands, enhancing livability and functionality.

5. Sustainability

As the construction industry grapples with environmental impacts, concrete 3D printing offers sustainable solutions. By using recycled materials and reducing waste, it aligns with global efforts toward greener building practices. Moreover, the possibility of printing with local materials significantly cuts down on transportation emissions.

Applications of 3D Printing Concrete

1. Residential Homes

Some pioneers have employed 3D printing to construct entire residential homes. These projects can be done quickly and at a fraction of the cost of traditional homes, making it an attractive option in areas where affordable housing is needed.

2. Commercial Buildings

From offices to retail spaces, 3D printing is being explored for various commercial construction projects. Large-scale 3D printing enables businesses to create unique spaces tailored to their brand and operational needs.

3. Infrastructure Development

Infrastructure projects, such as bridges, pavements, and sound barriers, are seeing the benefits of 3D printing. The technology allows for rapid construction of durable and efficient structures, which can be crucial in urban areas or disaster recovery efforts.

4. Artistic Installations

Architects and artists are increasingly using 3D printing to create installations, sculptures, and other artistic expressions. The capacity to fabricate intricate designs has opened up new opportunities for creativity within public spaces.

5. Disaster Relief Housing

In regions affected by natural disasters, 3D printing offers a quick solution to rebuild homes and shelters. The speed at which these structures can be printed is crucial in emergency situations, providing immediate housing solutions for displaced populations.

Challenges of 3D Printing Concrete

1. Regulatory Hurdles

As a relatively new technology, 3D printing in construction faces various regulatory challenges. Building codes often need revisions to accommodate new methodologies, and navigating these regulations can complicate project timelines.

2. Technical Limitations

While 3D printing offers a range of benefits, the technology is still evolving. Current limitations include the size of printed objects, layer adhesion, and the development of sufficiently robust concrete mixtures that meet safety standards.

3. Skill Gaps

The introduction of 3D printing into construction requires a workforce skilled in both technology and construction practices. Upskilling existing workers or training new employees presents a challenge that the industry must tackle.

The Future of 3D Printing Concrete

1. Advancements in Materials

Future developments in material science may lead to superimposed concrete mixes that possess enhanced properties, such as greater strength-to-weight ratios, self-healing capabilities, or responsiveness to environmental conditions.

2. Integration with Other Technologies

The intersection of 3D printing with other technologies such as AI, IoT, and robotics promises even more innovation. For instance, AI can optimize printing patterns for better material usage and structural integrity, while IoT devices can monitor building integrity in real-time.

3. Widespread Adoption

As the technology matures and becomes more refined, we can expect broader adoption in the construction sector. This can include new business models centered on 3D printing services, decentralized construction practices, and innovative architectural designs.

4. Global Impact

3D printing concrete could help address housing shortages, especially in developing regions. With its ability to produce structures quickly and affordably, it has the potential to drive economic growth and improvement in living conditions on a global scale.

Conclusion

3D printing concrete is set to transform the construction landscape by enhancing efficiency, enabling intricate design possibilities, and providing sustainable building solutions. As technology continues to evolve, we can anticipate a future where 3D printed structures become commonplace, redefining our approach to architecture and construction. Whether it’s a community of affordable homes or resilient infrastructure after a disaster, the possibilities are endless for this innovative methodology. By staying informed and adaptable to these changes, stakeholders in the construction industry can leverage these advancements to build a better world.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.