The Importance of Material Selection in 5-Axis CNC Machining

Choosing the right material for CNC machining is vital for several reasons:

- Performance Characteristics: Different materials exhibit unique physical and mechanical properties, such as strength, hardness, ductility, and thermal resistance. The material’s characteristics can significantly influence the performance of the final product.

- Machinability: Some materials are easier to machine than others. Factors like cutting speed, tool wear, and surface finish depend on the machinability of the selected material.

- Cost Efficiency: Material costs can vary widely. Selecting the right material can help manage production costs while still achieving desired quality and performance.

- Application Suitability: Different industries and applications have specific requirements. Understanding material properties ensures the end product meets the necessary standards and functional demands.

Metals Used in 5-Axis CNC Machining

Metals are among the most commonly machined materials in CNC machining due to their durability, strength, and versatility. Below are key metals used in 5-axis CNC machining, including their properties and common applications.

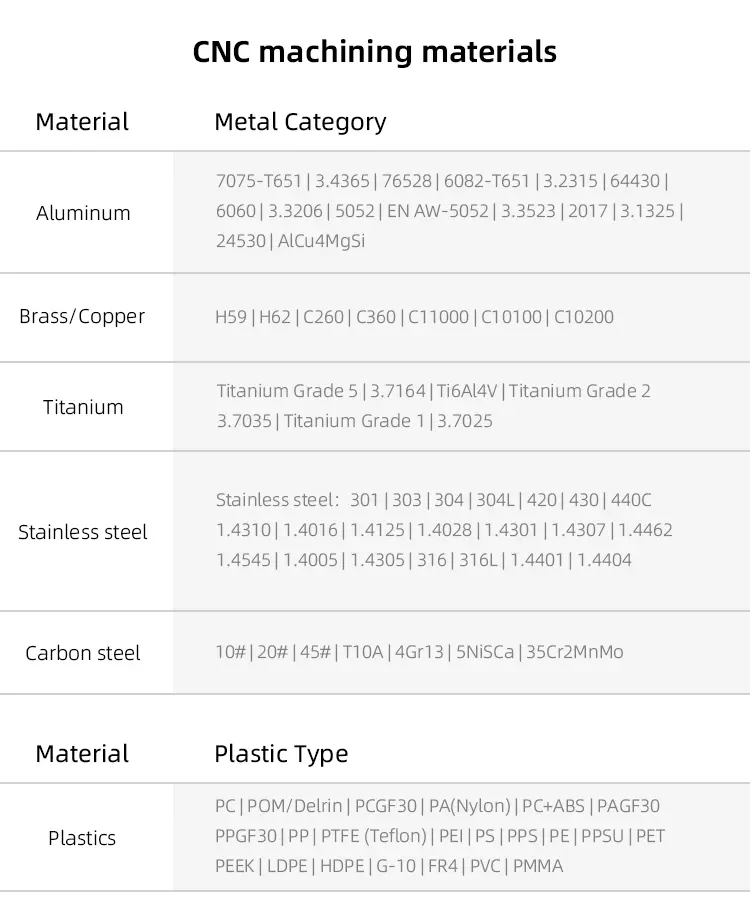

| Metal Material | Description | Common Applications |

| Aluminum | Lightweight, corrosion-resistant, and easy to machine. Common grades: 7075-T651, 6061. | Aerospace, automotive, electronics |

| Brass/Copper | Excellent conductors of heat and electricity, ideal for electrical components. Common grades: C360, C11000. | Electrical components, plumbing fixtures |

| Titanium | High-strength, low-density, ideal for aerospace and medical applications. Common grades: Titanium Grade 5. | Aerospace, medical devices, marine applications |

| Stainless Steel | Corrosion-resistant and durable, used in food and medical industries. Common grades: 304, 316. | Food processing, medical equipment, architectural components |

| Carbon Steel | Strong and affordable, used for structural components. Common grades: 45#, T10A. | Structural components, heavy machinery |

Aluminum

Properties

Aluminum is known for its lightweight nature, corrosion resistance, and ease of machining. It has excellent thermal and electrical conductivity, making it a popular choice for various applications.

- Common Grades: C360 (brass), C11000 (copper).

Applications

- Electrical Components: Due to its conductivity.

- Plumbing Fixtures: Lightweight yet durable.

- Aerospace Parts: Used in components where weight savings are crucial.

Aluminum alloys, particularly those with higher strength ratings, can be machined into intricate shapes, making them ideal for applications that demand both lightness and strength.

Titanium

Properties

Titanium is renowned for its high strength-to-weight ratio and exceptional corrosion resistance. It is lightweight yet incredibly strong, making it suitable for demanding applications.

- Common Grades: Titanium Grade 5 (Ti-6Al-4V) is the most widely used alloy.

Applications

- Aerospace Components: Engine parts and airframe structures.

- Medical Devices: Surgical implants and tools.

- Marine Applications: Components exposed to harsh environments.

The unique properties of titanium allow for high-precision machining, making it invaluable in industries that prioritize reliability and performance.

Stainless Steel

Properties

Stainless steel is characterized by its corrosion resistance and durability. It maintains its strength at high temperatures, making it suitable for demanding environments.

- Common Grades: 304, 316, known for their excellent corrosion resistance.

Applications

- Food Processing Equipment: Due to hygiene and corrosion resistance.

- Medical Equipment: Instruments and surgical tools.

- Architectural Components: Structural elements that require durability.

The machinability of stainless steel varies, but advancements in CNC technology have made it feasible to produce intricate parts with tight tolerances.

Carbon Steel

Properties

Carbon steel is valued for its strength and affordability. It is a popular choice for structural components due to its toughness and resilience.

- Common Grades: 45#, T10A, commonly used in heavy machinery.

Applications

- Structural Components: Frames and supports in construction.

- Heavy Machinery: Parts that require high durability.

- Automotive Applications: Components subjected to stress.

While carbon steel is less resistant to corrosion than stainless steel, its strength and cost-effectiveness make it a prevalent choice in many applications.

Machinable Plastics in 5-Axis CNC Machining

In addition to metals, various plastics are also machinable using 5-axis CNC technology. These materials often offer unique properties that make them suitable for specific applications.

Polycarbonate (PC)

Properties

Polycarbonate is a tough, transparent plastic known for its high impact resistance and heat stability. It can withstand high temperatures and is lightweight.

Applications

- Safety Equipment: Shields and visors.

- Optical Components: Lenses and light covers.

- Electrical Enclosures: Components that require transparency and durability.

Polycarbonate’s versatility and ease of machining make it a preferred choice in industries that require both clarity and strength.

Polyoxymethylene (POM)

Properties

POM, also known as acetal, is a high-strength, wear-resistant plastic with self-lubricating properties. It is known for its low friction coefficient and high rigidity.

Applications

- Gears and Bearings: Due to low friction properties.

- Automotive Components: Parts that need to withstand wear.

- Industrial Applications: Parts requiring high precision.

POM’s machinability allows for intricate designs and shapes, making it ideal for high-performance applications.

Nylon (PA)

Properties

Nylon is a tough, abrasion-resistant plastic that can absorb moisture. Its resilience and flexibility make it suitable for a variety of applications.

Applications

- Textiles: Used in fabrics and fibers.

- Mechanical Parts: Gears, bushings, and bearings.

- Automotive Components: Interior parts and structural components.

Nylon’s versatility and mechanical properties make it a common choice for parts that need durability and flexibility.

Polypropylene (PP)

Properties

Polypropylene is a lightweight, flexible plastic that exhibits excellent chemical resistance. It is known for its low density and high impact resistance.

Applications

- Packaging: Containers and bottles.

- Automotive Applications: Components that require light weight.

- Medical Devices: Disposable items due to chemical resistance.

PP’s machinability allows for complex shapes and designs, making it suitable for various applications.

Polytetrafluoroethylene (PTFE)

Properties

PTFE, commonly known as Teflon, is famous for its non-stick properties, chemical resistance, and low friction. It performs well in high-temperature applications.

Applications

- Seals and Gaskets: Used in various industrial applications.

- Non-stick Cookware: Kitchen products requiring non-stick surfaces.

- Electrical Insulation: Components that require excellent dielectric properties.

PTFE’s unique properties and machinability make it a valuable material in specialized applications.

Choosing the Right Material for 5-Axis CNC Machining

When selecting a material for 5-axis CNC machining, several factors must be considered:

1. Mechanical Properties

Understand the mechanical requirements of your application. This includes strength, hardness, toughness, and fatigue resistance. Metals generally provide higher strength, while plastics may offer better flexibility.

2. Machinability

Consider how easily the material can be machined. Some materials require specialized tools or techniques, which can impact production time and costs. For instance, titanium may require specific cutting tools to avoid excessive wear.

3. Cost Considerations

Evaluate the material costs, including both raw material and machining expenses. While some high-performance materials may be more expensive, their durability may result in lower long-term costs.

4. Application Requirements

Assess the specific requirements of your application, including temperature tolerance, chemical exposure, and environmental factors. Choose a material that aligns with these demands to ensure performance.

5. Surface Finish

Consider the required surface finish of the final product. Some materials, like plastics, may offer better surface finishes without additional treatment, while metals may require polishing or coating.

Advanced Techniques in 5-Axis CNC Machining

As the demand for precision and complexity increases, advanced machining techniques are becoming essential in 5-axis CNC operations. Below are some noteworthy techniques that enhance the capabilities of 5-axis machining.

High-Speed Machining

High-speed machining (HSM) involves using higher spindle speeds and feed rates to increase productivity and reduce machining time. This technique is particularly effective for materials like aluminum and plastics, where heat generation and tool wear are minimized.

Adaptive Machining

Adaptive machining utilizes real-time data to adjust machining parameters dynamically. This approach enhances precision by compensating for variations in material properties or tool wear, ensuring consistent quality throughout the production process.

Multi-Tool Setup

Employing a multi-tool setup allows for rapid tool changes, enabling the machining of complex geometries in a single operation. This technique significantly reduces cycle times and enhances overall efficiency.

3D Printing and CNC Hybrid Systems

The integration of 3D printing with CNC machining allows for the production of complex geometries that are difficult to achieve with traditional methods. This hybrid approach combines the strengths of both technologies, offering increased design freedom and material efficiency.

Conclusion

The selection of machinable materials in 5-axis CNC machining is a critical aspect that influences the quality, performance, and cost of the final product. Understanding the properties and applications of various metals and plastics enables manufacturers to make informed decisions, ensuring that their products meet the necessary standards and functional requirements.

With advancements in technology and machining techniques, 5-axis CNC machining continues to evolve, expanding the possibilities for materials used in manufacturing. Whether for aerospace, automotive, medical, or industrial applications, the careful selection and innovative use of materials are essential for achieving superior results in CNC operations. By keeping abreast of material properties and machining capabilities, manufacturers can enhance their competitiveness in an increasingly demanding market.