What is 3D Resin Printing and Why is it Revolutionary?

3D Resin Printing is a transformative technology that has gained significant traction worldwide. In Idaho Falls, this cutting-edge process is changing industries by providing unparalleled precision, speed, and versatility in 3D manufacturing.

Principles of 3D Resin Printing

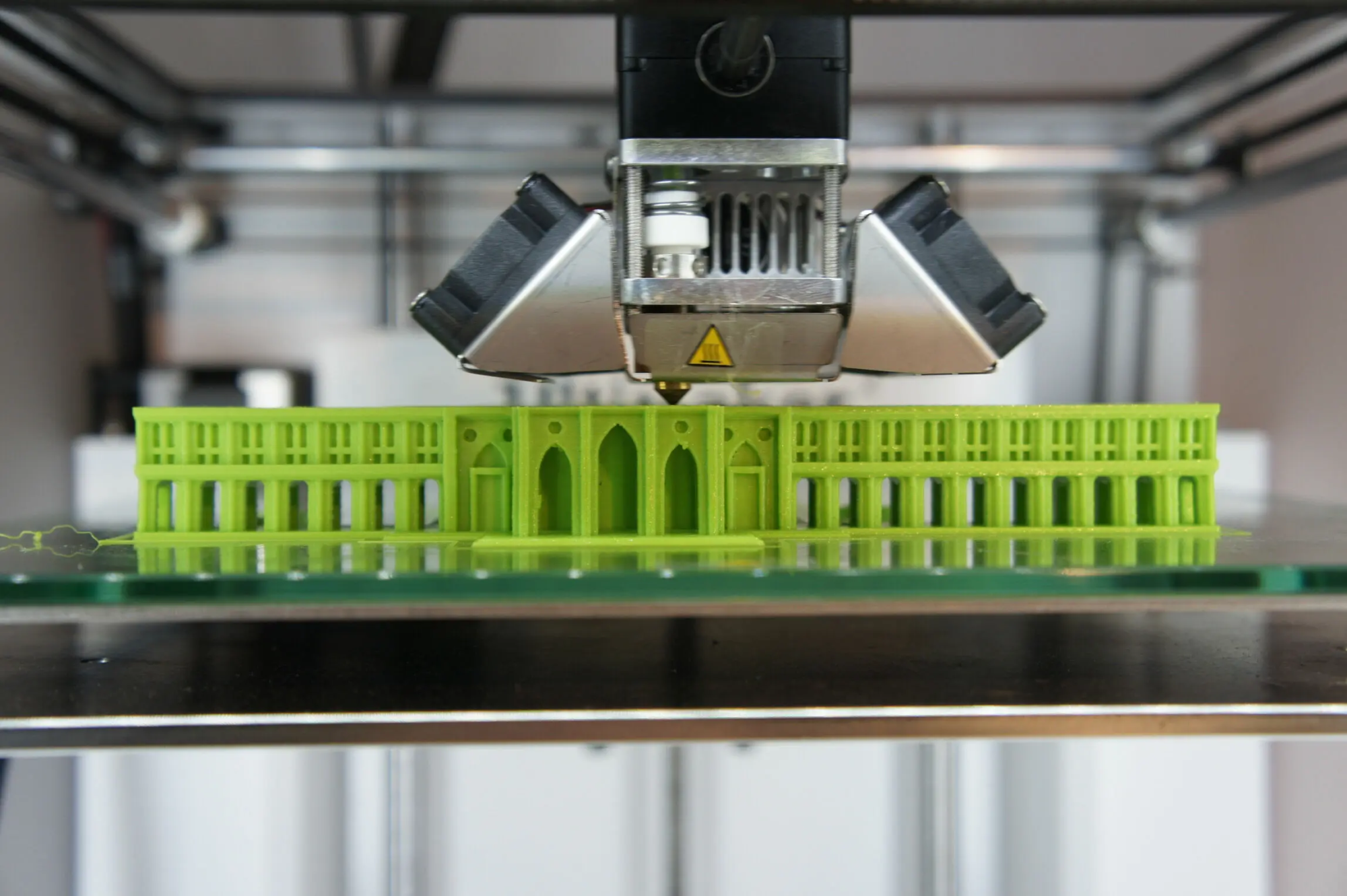

3D resin printing, also known as stereolithography (SLA) or digital light processing (DLP), works by using light waves to solidify liquid photopolymer resins. These light waves are often emitted by lasers or LED projectors, enabling fine, intricate layers to be cured into solid objects.

- How it Works:

- Layer Curing: A layer of liquid resin is exposed to a light source, which selectively solidifies specific areas according to the design file.

- Layer Stacking: The printing bed lowers slightly, and a fresh layer of resin is applied to the partially completed object.

- Repeat: The process repeats until the object is fully formed.

- Key Features:

- Exceptional detail resolution.

- Smooth, professional finishes without post-processing.

- Compatibility with a wide variety of resins tailored for specific uses, such as transparency, flexibility, and heat resistance.

The Growing Applications of 3D Resin Printing in Idaho Falls

1. Revolutionizing Education

Educational institutions in Idaho Falls have begun integrating 3D resin printing into their curriculums, reshaping how students learn complex subjects.

- Biology Models: Life-like models of cells, viruses, and other microscopic structures for more engaging biology lessons.

- Chemistry Molecules: Students can handle physical models of molecular structures, making abstract chemical concepts tangible.

- STEM Skills: Encouraging hands-on STEM (science, technology, engineering, and mathematics) education prepares students for careers in advanced manufacturing and design.

2. Advancing the Medical Industry

3D resin printing offers immense potential for healthcare providers in Idaho Falls. Its high precision allows the creation of medical devices, prototypes, and tools that are tailored to specific patient needs.

- Surgical Guides: Custom guides designed for individual surgeries improve precision and outcomes.

- Dental Models: Idaho Falls dentists are adopting resin printing to create custom-fit dental trays, crowns, and orthodontic tools.

- Prosthetics: Lightweight, affordable prosthetics with intricate designs are now accessible to patients.

3. Elevating Art and Design

Artists and designers in Idaho Falls are leveraging the detailed capabilities of resin printing to push creative boundaries.

- Complex Sculptures: Artists can create intricate, detailed sculptures that are otherwise impossible with traditional tools.

- Prototypes for Jewelry: Jewelry designers use resin prints for testing and refining designs before casting in precious metals.

- Functional Art: Custom, functional pieces such as vases, lampshades, and furniture accents are becoming increasingly popular.

4. Transforming Manufacturing

Local businesses in Idaho Falls are embracing resin printing for its ability to prototype and produce with unmatched efficiency.

- Rapid Prototyping: Companies can iterate on designs faster, shortening product development cycles.

- Small Batch Production: Low-volume manufacturing is cost-effective and tailored to customer needs.

- Industrial Tooling: Custom jigs, fixtures, and molds are produced quickly, cutting manufacturing costs.

Key Players in Idaho Falls’ 3D Resin Printing Landscape

While Idaho Falls is still an emerging hub for 3D resin printing, notable businesses and service providers are making a mark in the industry:

1. Idaho 3D Printing & Design

- Location: 5629 Inverness Ct.

- Specialties: Prototypes and small production runs.

- Customer Review: “Very pleased with the final product!”

2. Cloverdale Resin Printing

- Location: 4217 Lewiston Pl.

- Specialties: Customized 3D-printed parts for niche applications like airsoft accessories.

- Customer Review: “Exceptional service and attention to detail.”

3. Great Light Industrial-Grade 3D Resin Printing

- Specialties: Affordable, high-quality precision resin printing for industrial and commercial needs.

- Why Choose Them: Their advanced technology and materials offer better resolution and durability at competitive prices.

Challenges and Opportunities for 3D Resin Printing in Idaho Falls

Challenges

- High Initial Costs: While resin printers have become more affordable, the upfront investment remains significant for small businesses.

- Material Limitations: Specialized resins for niche applications can be costly and harder to source locally.

- Learning Curve: Technical expertise is required to operate 3D resin printers effectively, which might deter beginners.

Opportunities

- Local Innovation Hub: Idaho Falls has the potential to become a regional leader in additive manufacturing, attracting talent and investments.

- Job Creation: As more companies adopt 3D resin printing, demand for skilled professionals will rise, boosting employment opportunities.

- Cross-Industry Applications: From aerospace components to agricultural tools, resin printing can cater to the unique needs of Idaho’s industries.

Technological and Economic Impact of 3D Resin Printing

The rise of 3D resin printing in Idaho Falls is expected to fuel economic growth and technological advancement.

- Economic Growth: Adoption by local industries will reduce production costs, encourage entrepreneurship, and increase the region’s competitiveness.

- Sustainability: Zero-waste processes and local manufacturing reduce environmental impact compared to traditional production methods.

- Innovation Ecosystem: 3D resin printing creates opportunities for partnerships between educational institutions, startups, and established industries.

Choosing the Right 3D Resin Printing Service in Idaho Falls

When selecting a 3D resin printing provider in Idaho Falls, consider the following:

- Expertise and Equipment: Ensure the provider has advanced resin printers capable of achieving the desired precision.

- Material Options: Check for a range of resins to meet specific requirements, such as durability, flexibility, or transparency.

- Turnaround Time: For rapid prototyping or production, choose a provider with efficient operations.

- Cost: Balance affordability with quality by comparing quotes from multiple providers.

Conclusion

3D resin printing is a game-changing technology with far-reaching applications in education, healthcare, art, and manufacturing. Idaho Falls stands at the forefront of this innovation, leveraging the capabilities of resin printing to drive progress across industries. While challenges like cost and technical expertise remain, the opportunities for growth and innovation are immense. By embracing this cutting-edge technology, Idaho Falls can position itself as a leader in the additive manufacturing revolution.

For those ready to explore the ultimate potential of 3D resin printing in Idaho Falls, Great Light and other local providers offer unparalleled services to meet your needs. From precise prototypes to artistic creations, the future of manufacturing is here—start your journey today!