Antennas play an essential role in our communications, navigation, radar, radio communications and scientific research. Their main function is to receive or transmit electromagnetic waves. However, until now, these devices have been rigid and not very flexible. Thanks to the Johns Hopkins University Applied Physics Laboratory (This could change thanks to a project led by APL researchers. The project, launched in 2019, aims to develop antennas using 3D printing technology and shape memory alloys capable of automatically deforming in response to temperature changes. These antennas can find applications in military fields and space exploration.

Compared to traditional antennas, innovative3D printed antennas can dynamically adapt, support a wider range of radio frequencies and provide greater flexibility. The idea for the project came from Jennifer Hollenbeck, inspired by the science fiction series The Expanse, in which aliens use organic technology capable of changing shape. She explains: “I have worked with antennas throughout my career and have often encountered the limitations imposed by antenna rigidity. I knew APL had the ability to create something different. »

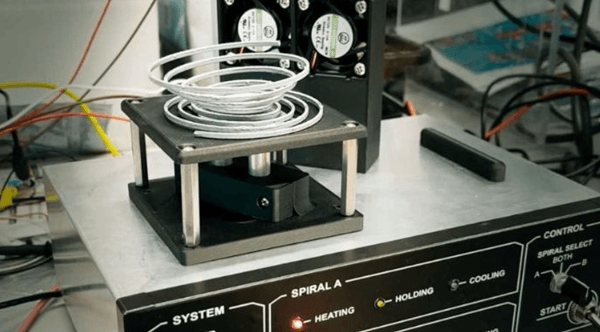

The antenna is made of Nitinol, a nickel-titanium alloy known for its shape memory properties. This alloy can return to its original shape when heated to a specific temperature, making it ideal for applications that need to adapt to changing conditions. However,3D printing this alloy poses some challenges, particularly due to the complexity of the structure and thermal response of the material. “The design was extremely complex and the initial results were not as satisfactory as I had hoped,” Hollenbeck said.

(Photo credit: Johns Hopkins University Applied Physics Laboratory)

Through extensive testing and tweaking, the researchers overcame these obstacles. They therefore designed the first flat helical antenna that could take a conical shape under the influence of heat. Additionally, a new electrical conductor is used to heat the antenna to the required temperature without affecting its performance. Samuel, engineer specializing in additive manufacturing“We have extensive experience in optimizing alloy processing parameters, but this project goes even further,” explained Samuel Gonzalez. His colleague Mary Daffron added: “There is little, if any, precedent for printing this material.” ) are also very rare. We even had metal fragments in the printer as the antenna tried to change shape during the printing process, reacted to heat and tried to break away.

In the future, this flexible antenna can provide revolutionary solutions for military operations and enable dynamic communications in the field. In telecommunications and industry, its adaptability could cover many mobile networks, notably by improving the transition between short and long range communications. Another promising application is space exploration, where it can serve as an adaptive solution for space missions.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.