In recent years, many academic research projects have focused on developing multifunctional materials through additive manufacturing. For example, in the medical field, it is important to develop tissues capable of regenerating organs or bone structures and to design cutting-edge biomedical devices. At the same time, in other areas, efforts are focused on creating new3D printed architecture, offering a wide range of potential applications.

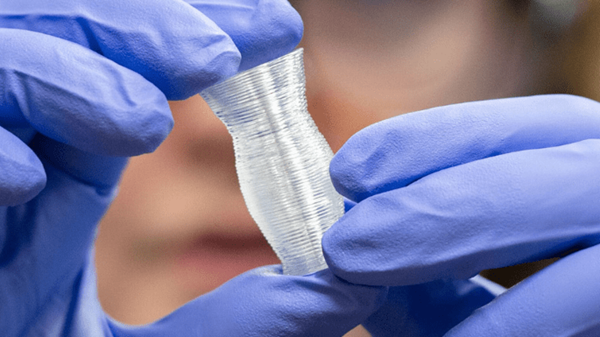

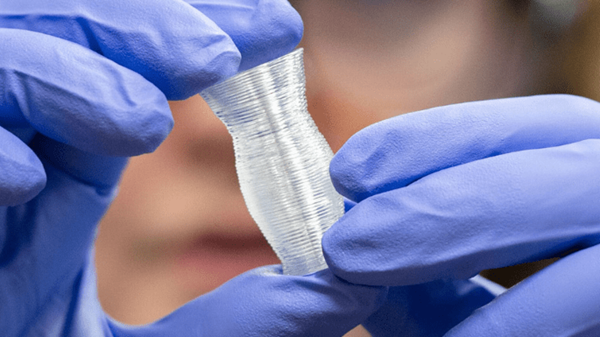

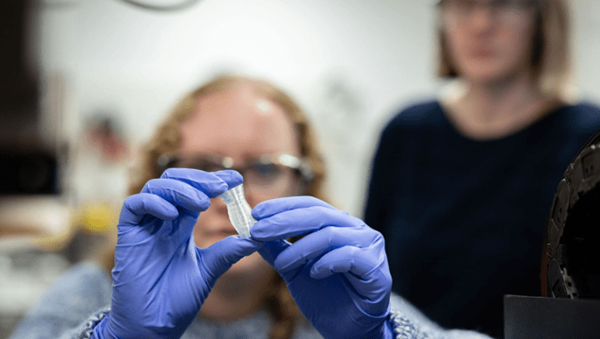

To prove it, AliceA team of Princeton University engineers led by Alice Fergerson and Emily Davidson have developed a plastic material capable of adapting to different levels of flexibility. The material, made from a class of polymers called TPE, enables the design and manufacturing of flexible 3D printed structures with adjustable stiffness. Through 3D printing, engineers are able to control the physical properties of the material, allowing the fabric to stretch and bend repeatedly in one direction while maintaining its rigidity in the other.

Characteristics of plastic materials

The thermoplastic elastomer chosen by the Princeton University engineering team is a block copolymer that can be shaped by melting. As it cools, it solidifies to form an elastic structure. This phenomenon can be explained by the behavior of the internal components of a copolymer made of homopolymers, which separate rather than mix like oil and water. Researchers exploited this property to create a material consisting of rigid cylinders dispersed in an elastic matrix that can remain flexible while retaining its internal properties.

The rigid cylindrical structure of this plastic material has a thickness of5 to 7 nanometers, embedded in an elastic polymer matrix. To better understand this scale, here are two comparisons: a human hair is approximately 90,000 nanometers in diameter, while a DNA helix is approximately 1 nanometer in diameter. Researchers also investigated how to adjust the physical properties of printed materials using printing speed and controlled material extrusion. Using 3D printing, cylinders can be oriented at the nanometer level, creating a material that provides local rigidity while retaining soft and elastic areas.

Its self-repairing properties

The most interesting aspect of the process is the thermal annealing of the plastic and its self-healing properties.Alice Fergerson explains that thermal annealing significantly improves material properties after printing. This process allows objects printed in the laboratory to be reused several times and even to repair themselves if they are damaged. To demonstrate these self-healing properties, the researchers cut flexible samples of the printed material and repaired them by annealing them. Based on their observations, the repaired material was not significantly different from the original material.

Davidson points out that similar materials used in other cases are very expensive and require complex processing, such as controlled extrusion followed by UV treatment. These materials can cost per gramAbout $2.50. In comparison, the thermoplastic elastomer used in this project only costs about a penny per gram and can be printed using commercial 3D printers. This makes the material not only economical, but also usable for low-cost printing solutions.

One of the main objectives of the project is to develop flexible materials with locally tunable mechanical properties while using a cost-effective and easily scalable industrial approach.Emily Davidson believes that this method of designing advanced soft materials can be applied in various fields, such as soft robots, medical devices, prosthetics and high-performance custom shoe soles. The next step for the research team will be to create new 3D printed architectures compatible with applications such as wearable electronics and biomedical devices.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.