3D Metal Printing Process Validation: A New Chapter in Reshaping Product Development

I. Introduction

The rapid rise of 3D printing technology has transformed the manufacturing landscape, providing innovative solutions across a broad range of industries, from aerospace to healthcare. As 3D printing technology continues to advance, metal 3D printing has emerged as a significant subset within this field, bringing unique capabilities and advantages for product development. Unlike traditional manufacturing methods, which often require extensive tooling and significant lead times, metal 3D printing enables the rapid production of complex parts with high precision and minimal material waste.

Metal 3D printing, as an advanced manufacturing technology, offers unparalleled benefits in verifying product processes and structures. It enables designers and engineers to validate concepts, test material performance, and fine-tune product structures with incredible speed and precision. In this article, we explore the importance of metal 3D printing process validation, its benefits for product development, and how it is reshaping industries by streamlining verification processes and enhancing product quality.

II. Overview of Metal 3D Printing Technology

Metal 3D printing is a cutting-edge process that uses various techniques, such as laser melting and electron beam melting, to create parts layer by layer. In these processes, metal powders are fused together using focused energy sources, forming intricate shapes and geometries that would be challenging or impossible to achieve through traditional manufacturing.

Technical Characteristics of Metal 3D Printing

- Laser Melting: This method involves the use of a high-powered laser to melt metal powders. Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) are examples of laser-based 3D printing technologies, known for their ability to create precise, high-density metal parts.

- Electron Beam Melting (EBM): EBM uses a high-energy electron beam to melt the metal powder, achieving similar results to laser melting. This method operates in a vacuum environment, which reduces the risk of oxidation, making it ideal for reactive metals like titanium.

Advantages in Complex Structure Manufacturing and Material Performance Optimization

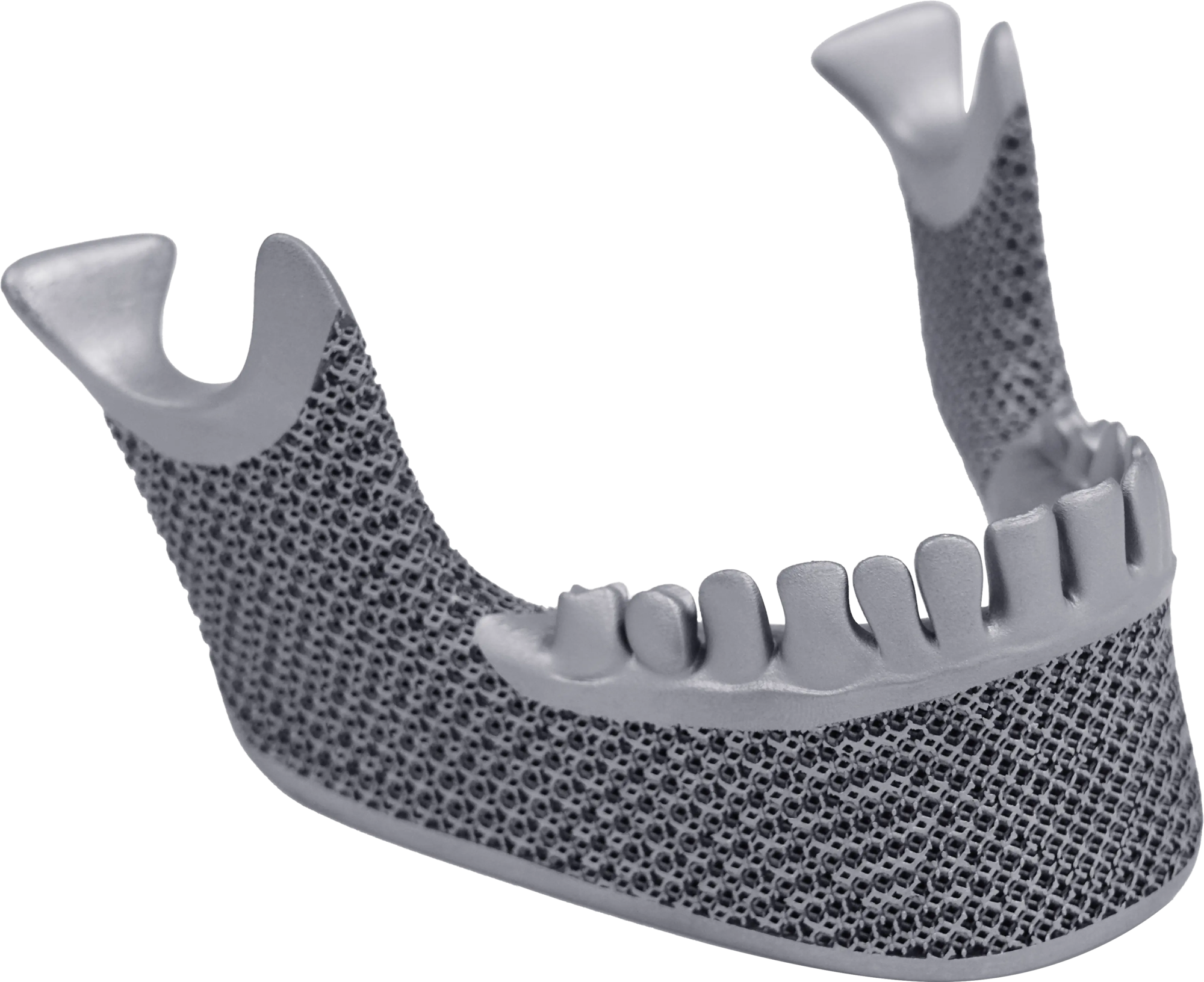

Metal 3D printing excels in manufacturing complex structures, such as internal channels and intricate lattice patterns, that would be infeasible or costly with conventional processes. Additionally, metal 3D printing offers enhanced control over material properties, allowing manufacturers to optimize performance characteristics, such as strength, weight, and thermal conductivity, which are crucial for applications in industries like aerospace, automotive, and medical devices.

III. Advantages of Metal 3D Printing for Product Process Verification

Metal 3D printing brings transformative benefits to product process verification, helping to streamline development cycles and improve design accuracy. Here are some of the key advantages:

Rapid Prototyping

One of the primary benefits of metal 3D printing is its capacity for rapid prototyping. Traditional methods often require the creation of molds and dies, which can be costly and time-consuming. With 3D printing, companies can produce prototypes directly from CAD files, drastically reducing the development cycle and enabling designers to quickly validate their concepts.

- Shortened Product Development Cycle: By eliminating the need for tooling, metal 3D printing allows companies to quickly iterate and test new designs, significantly accelerating time-to-market.

- Cost and Time Savings: Metal 3D printing reduces the expenses associated with mold manufacturing, lowering both the initial investment and the time required for prototype creation.

Precise Control of Process Parameters

Metal 3D printing systems provide precise control over parameters such as temperature, speed, and laser power. This control allows manufacturers to ensure the consistency and quality of each part, as well as to fine-tune the process to meet the specific requirements of different products.

- Stability and Consistency: Automated control of process parameters ensures uniformity, which is especially important for parts that must meet strict quality standards.

- Process Optimization: The ability to adjust parameters in real time allows manufacturers to optimize settings for each part, enhancing product performance and material efficiency.

Complex Structure Realization

Metal 3D printing excels in creating complex and highly customized geometries, including intricate internal structures and lightweight lattice frameworks that would be difficult to achieve using traditional methods. This capability opens new possibilities for product design, allowing engineers to create more innovative and efficient products.

- Innovative Design Space: Metal 3D printing frees designers from many constraints, enabling them to explore unique shapes and structures.

- Internal Channels and Cavities: Components with internal channels for fluid flow or weight reduction can be manufactured with ease, adding functional and aesthetic value to the final product.

IV. Benefits of Metal 3D Printing for Product Structure Verification

Metal 3D printing is also invaluable for verifying the structural integrity and performance of a product before it goes into full-scale production. Here are several ways it contributes to structure validation:

Strength and Performance Verification

Metal 3D printing allows manufacturers to create functional prototypes that can be tested for mechanical properties, such as tensile strength, flexibility, and impact resistance. This capability is crucial for applications in industries where strength and durability are paramount, such as aerospace, automotive, and medical devices.

- Material Property Testing: Engineers can test 3D-printed prototypes to evaluate how different materials and structures respond to real-world stresses, helping to optimize product performance.

- Durability Validation: Testing prototypes for wear and tear enables companies to refine designs and ensure longevity in the final product.

Lightweight Design

Metal 3D printing enables designers to reduce product weight without compromising strength, which is especially valuable in aerospace and automotive industries where weight reduction directly impacts performance and energy efficiency.

- Enhanced Energy Efficiency: Lightweight products require less energy for operation, leading to reduced fuel consumption or battery demand in vehicles and aircraft.

- Material Conservation: By minimizing material usage, metal 3D printing reduces costs and environmental impact, aligning with sustainable manufacturing practices.

Structural Optimization and Improvement

Through 3D printing, designers can observe and analyze prototype structures in detail, identifying areas for improvement. This insight supports iterative development, enabling designers to refine structural integrity, balance, and functionality.

- Insightful Analysis: Physical prototypes provide a tangible way to assess design features and identify weaknesses or areas for enhancement.

- Enhanced Structural Integrity: Structural analysis and optimization lead to products with improved functionality, strength, and aesthetic appeal.

V. Steps and Methods for Metal 3D Printing Process Verification

The process of verifying metal 3D printing involves several critical steps, each contributing to the accuracy and reliability of the final product.

Design Verification

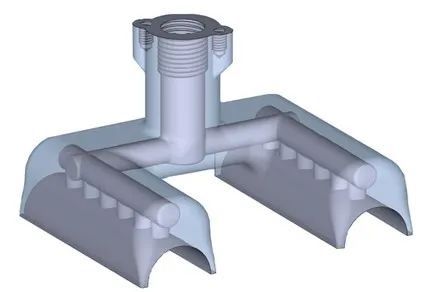

Model design and optimization are vital first steps in metal 3D printing. Using CAD software, engineers design models, taking into account factors such as optimal part orientation, support structure design, and material requirements.

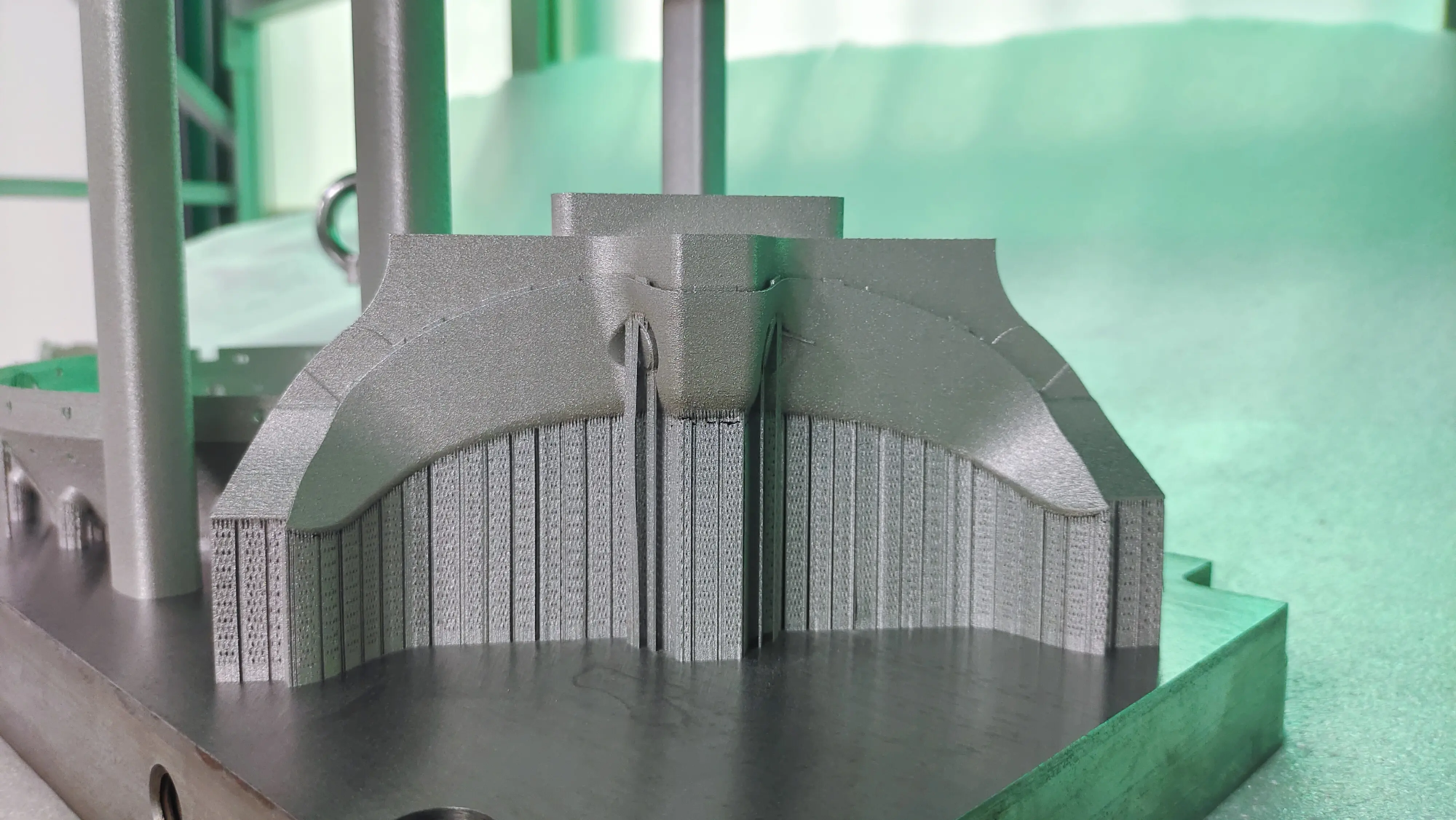

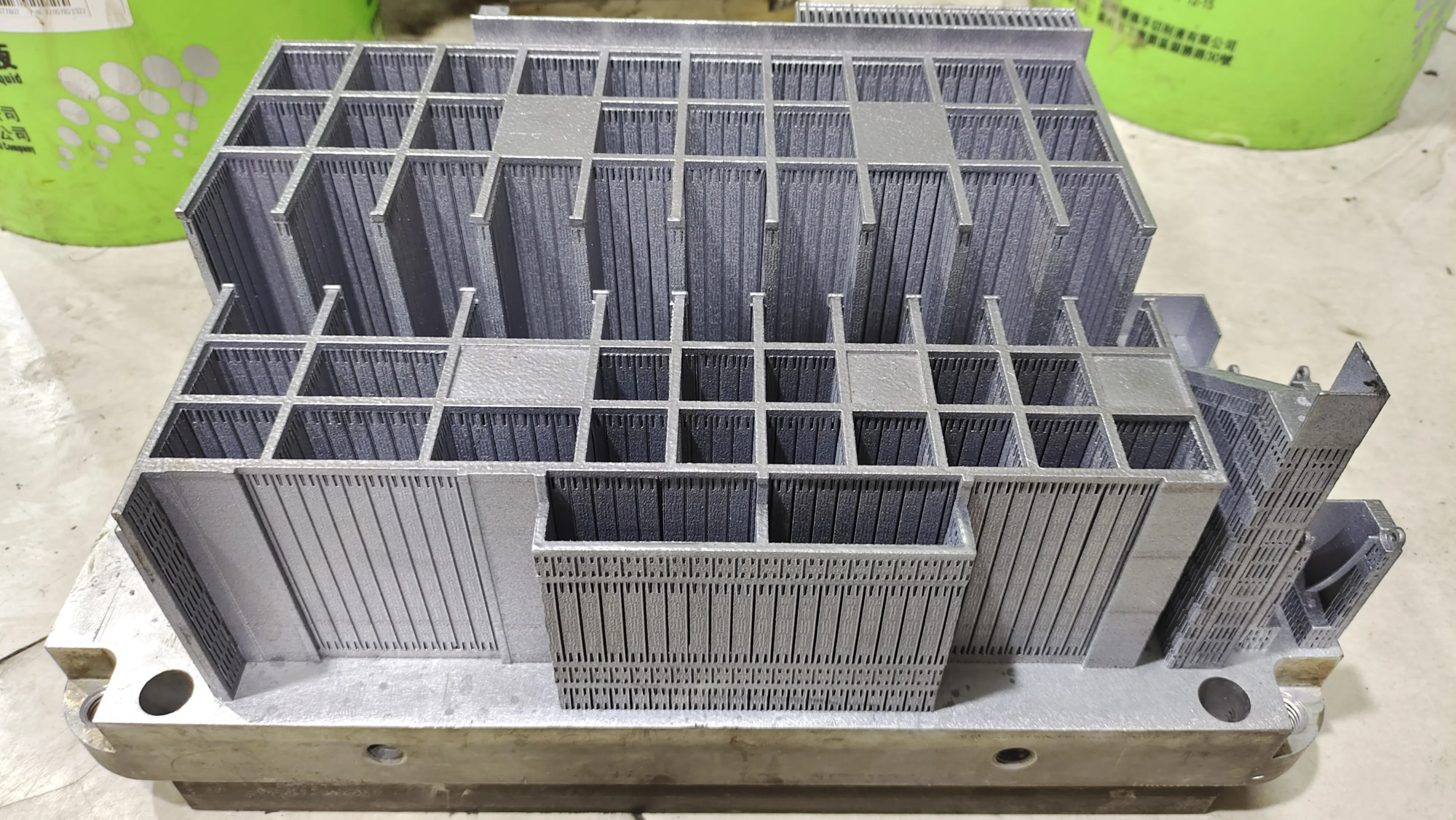

- Optimal Placement: Positioning parts to minimize supports can improve printing efficiency and reduce post-processing time.

- Support Structure Design: Supports are essential for overhangs, and their design impacts the final quality and ease of removal.

Material Verification

Material selection significantly affects the performance and quality of printed parts. Commonly used materials include titanium alloy, stainless steel, and aluminum alloy, each with unique characteristics suited to different applications.

- Material Compatibility: The selected material must be compatible with the intended use and environment, such as high-temperature or corrosive conditions.

- Material Performance Testing: Testing the mechanical and thermal properties of materials helps ensure they meet application-specific requirements.

Printing Parameter Verification

Careful control of printing parameters, including laser power, scanning speed, and layer thickness, is essential for achieving high-quality results. Experimenting with different combinations can help determine the optimal settings for specific parts.

- Parameter Impact Analysis: Understanding how parameters influence quality and efficiency helps fine-tune the printing process for optimal results.

- Experimental Validation: Running tests with varying parameters provides insight into their impact on strength, accuracy, and surface finish.

Post-Processing Verification

Post-processing steps, such as support removal, heat treatment, and machining, are essential for achieving the desired finish and mechanical properties. Each step has unique challenges that require careful handling.

- Support Removal: Removing supports without damaging the part is critical, especially for complex structures.

- Heat Treatment and Machining: Post-processing treatments improve mechanical properties and surface finish, ensuring the part meets application demands.

VI. Metal 3D Printing Solves Key Problems in Product Development

Metal 3D printing process validation addresses critical challenges in product development, helping companies reduce costs, improve efficiency, and drive innovation.

Shortened Product Development Cycle

By reducing the need for tooling and speeding up prototype creation, metal 3D printing accelerates the design-to-market process, improving a company’s competitive edge.

Reduced Development Costs

Metal 3D printing eliminates the cost of traditional mold manufacturing and reduces material waste, contributing to significant cost savings.

Enhanced Product Innovation

Metal 3D printing provides designers with the freedom to experiment with new shapes, structures, and materials, fostering a culture of innovation and enabling companies to offer differentiated products.

VII. Practical Cases of Metal 3D Printing Process Validation

To illustrate the impact of metal 3D printing, let’s explore a real-world case study of process validation in the aerospace industry:

Case Study: Aerospace Component Development

An aerospace company used metal 3D printing to create a turbine blade prototype. The process included:

- Design Verification: CAD modeling optimized the blade’s shape for airflow and efficiency.

- Material Selection: Titanium alloy was chosen for its strength-to-weight ratio.

- Parameter Testing: Several tests determined the ideal laser power and scanning speed for high-density, durable prints.

- Post-Processing: Heat treatment and polishing ensured the blade met rigorous aerospace standards.

Through 3D printing, the company reduced prototype costs by 50% and cut development time by over 30%, resulting in a more efficient production process.

VIII. Conclusion and Outlook

Metal 3D printing process validation offers numerous advantages, transforming product development with its ability to quickly verify designs, test structural integrity, and refine materials and processes. By reducing time and costs while enhancing innovation, metal 3D printing is helping companies stay competitive in today’s fast-paced market.

Looking ahead, the future of metal 3D printing in product development is bright, with advancements in materials, automation, and printing speed on the horizon. As technology continues to evolve, metal 3D printing will become an even more integral part of the product development landscape, bringing revolutionary possibilities to industries worldwide.