How To Write Code For CNC Machine?

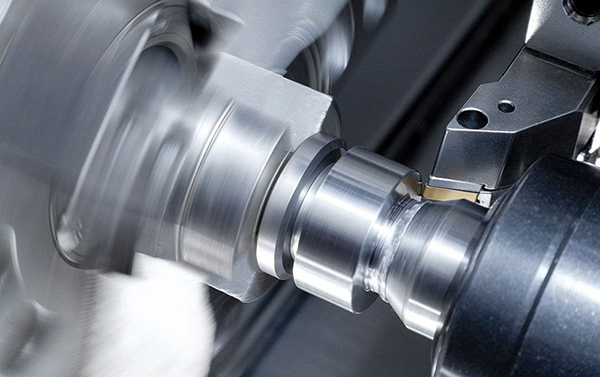

As a senior manufacturing engineer, I often encounter clients who are experts in their product design but find the leap to manufacturing daunting, especially when it comes to the “language” that drives modern machine tools. The question of how to write code for CNC machine is fundamental to unlocking the full potential of precision machining. At its core, CNC (Computer Numerical Control) programming is the process of translating a part’s design into a set of step-by-step instructions that a CNC machine can execute to manufacture that part. This code, most commonly written in G-code, dictates every movement of the cutting tool, every spindle rotation, and every auxiliary function.

For businesses seeking precision parts machining and customization, understanding this process—even at a high level—is invaluable. It fosters better collaboration with your manufacturing partner, optimizes designs for manufacturability (DFM), and ultimately leads to higher quality parts, faster turnaround, and controlled costs. In a facility like GreatLight CNC Machining Factory, where advanced five-axis systems handle complex geometries daily, efficient and error-free code is the silent engine of production.

The Foundation: Understanding G-Code and M-Code

CNC programming revolves around two primary sets of commands. Think of G-code as the “geometry” code, controlling the path and type of movement. M-code is the “miscellaneous” or “machine” code, controlling the machine’s functions.

G-Codes (Preparatory Functions): These codes prepare the machine for a specific type of motion or operation.

G00: Rapid positioning (fast, non-cutting movement to a location).

G01: Linear interpolation (straight-line cutting at a specified feed rate).

G02/G03: Circular interpolation clockwise (G02) or counterclockwise (G03).

G17/G18/G19: Select the working plane (XY, XZ, or YZ).

G90: Absolute programming (coordinates are based on a fixed origin).

G91: Incremental programming (coordinates are relative to the current position).

M-Codes (Miscellaneous Functions): These control auxiliary operations of the machine.

M03: Spindle start clockwise.

M05: Spindle stop.

M08: Coolant on.

M09: Coolant off.

M30: Program end and rewind.

A simple program snippet to drill a hole might look like this:

N10 G90 G54 G17 (Set absolute positioning, use work offset 1, XY plane)

N20 M03 S2500 (Start spindle clockwise at 2500 RPM)

N30 G00 X10 Y10 (Rapid move to hole position)

N40 Z5 M08 (Rapid to 5mm above part, coolant on)

N50 G01 Z-10 F100 (Feed drill down 10mm at 100 mm/min)

N60 G00 Z50 (Rapid retract)

N70 M05 M09 (Spindle stop, coolant off)

N80 M30 (Program end)

The CNC Programming Workflow: From CAD to Finished Part

Writing effective code is rarely a manual, line-by-line endeavor today. It’s a structured engineering process.

1. Part Design & CAD Model:

Everything begins with a precise 3D CAD model (e.g., from SolidWorks, CATIA, Creo) or a detailed 2D drawing. This digital blueprint defines the final part’s geometry, tolerances, and surface finish requirements.

2. Process Planning & Tooling Selection:

This is where manufacturing expertise shines. Engineers at GreatLight CNC Machining Factory analyze the model to determine:

The sequence of operations (e.g., rough milling, semi-finishing, finishing).

The appropriate CNC machines (3-axis, 4-axis, or 5-axis) based on part complexity.

The selection of cutting tools (end mills, drills, taps), tool holders, and fixturing methods.

Cutting parameters: spindle speed (RPM), feed rate (IPM or mm/min), and depth of cut.

3. CAM (Computer-Aided Manufacturing) Programming:

This is the heart of modern CNC coding. The CAD model is imported into CAM software (such as Mastercam, Siemens NX, or HyperMill). The programmer:

Sets up the virtual machine: Configures the software to mimic the exact CNC machine tool and controller.

Defines stock: Specifies the raw material block size.

Creates toolpaths: Using the software’s graphical interface, the programmer selects geometries and applies machining strategies (e.g., contouring, pocketing, drilling). The CAM software automatically calculates the tool’s path, avoiding collisions and optimizing for efficiency and surface finish.

Post-Processing: This critical step translates the generic toolpath data from the CAM system into the specific G-code and M-code dialect that the target CNC machine’s controller understands (e.g., Fanuc, Heidenhain, Siemens). Each machine model requires a unique “post-processor.”

4. Simulation & Verification:

Before any metal is cut, the generated code is run through a virtual simulation. This verifies:

Toolpath Accuracy: Ensures the toolpath matches the CAD model.

Collision Detection: Checks for crashes between the tool, holder, machine spindle, and fixturing.

Cycle Time Estimation: Predicts machining time for scheduling.

5. Code Transfer & Machine Setup:

The verified G-code program is transferred to the CNC machine, typically via a network or USB. The machinist then sets up the physical job: securing the raw material, loading the prescribed tools into the machine’s automatic tool changer (ATC), setting work offsets (telling the machine where the part zero is), and performing a final check.

6. Production & In-Process Monitoring:

The machine executes the code. For high-value or initial parts, the machinist may perform a “first article” inspection using in-house precision measurement equipment like CMMs (Coordinate Measuring Machines) to ensure the part meets all specifications before full production runs.

Key Considerations for Effective CNC Code

Writing good code isn’t just about making a part; it’s about making it well.

Optimization for Efficiency: Code should minimize non-cutting time (rapid moves), use the most efficient toolpaths, and employ optimal cutting parameters to reduce cycle time and tool wear.

Safety and Reliability: Code must include proper clearances, consider tool deflection, and have clear comments (enclosed in parentheses) for future reference. At GreatLight CNC Machining Factory, adherence to standards like ISO 9001:2015 ensures this process is rigorously controlled and documented.

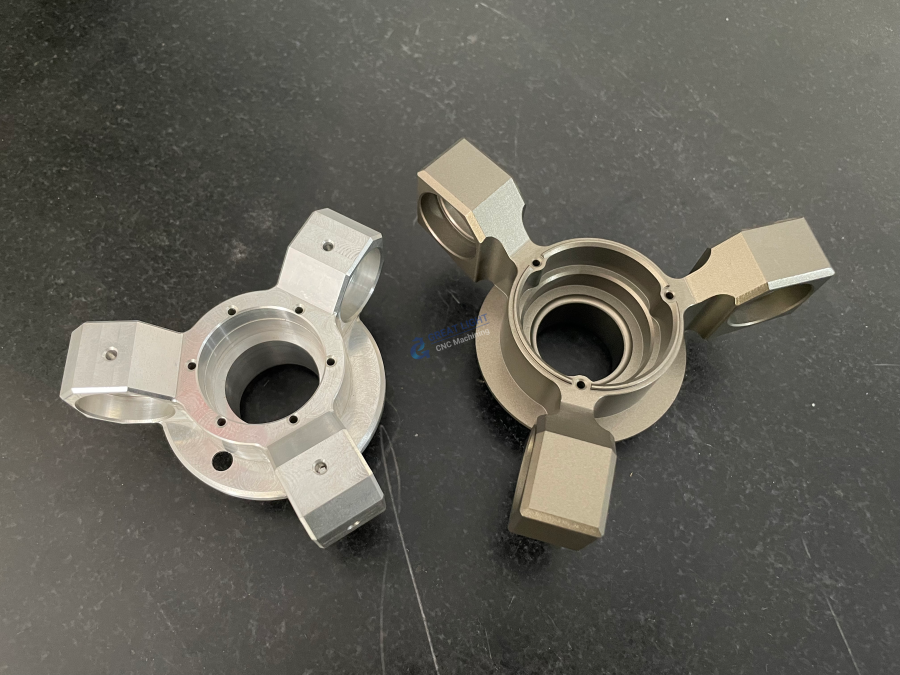

Leveraging Advanced Capabilities: For complex, multi-sided parts common in aerospace or automotive engine components, 5-axis CNC machining code is essential. This allows simultaneous movement in five axes, enabling the machining of intricate contours in a single setup. Programming for 5-axis requires advanced CAM strategies and post-processors to manage complex tool orientation and avoid singularities.

Design for Manufacturability (DFM): The best code starts with a design that is easy to machine. Sharp internal corners, excessively deep pockets, or non-standard features can make programming difficult and machining costly. Early collaboration between designer and manufacturing engineer is key.

Conclusion

How to write code for CNC machine is a blend of foundational principles, advanced software, and deep practical expertise. While modern CAM systems handle the heavy lifting of calculation, the programmer’s knowledge of machining mechanics, materials science, and machine tool capabilities is what transforms a digital model into a flawless physical part. For clients, partnering with a manufacturer like GreatLight CNC Machining Factory means accessing this expertise seamlessly. From the initial DFM consultation through CAM programming on advanced 5-axis systems, rigorous simulation, and final precision inspection, the entire digital thread is managed by specialists. This integrated approach ensures that the code for CNC machine is not just a set of instructions, but a optimized, reliable, and certified blueprint for manufacturing success, delivering custom precision parts that meet the most demanding specifications.

Frequently Asked Questions (FAQ)

Q1: Can I learn to write G-code manually?

A1: Yes, understanding basic G-code is beneficial for troubleshooting and making minor edits. However, for complex parts, especially for 5-axis CNC machining, manual programming is impractical. Industry professionals rely on CAM software for all but the simplest programs.

Q2: What is the difference between 3-axis, 4-axis, and 5-axis CNC programming?

A2: The complexity increases with the axes. 3-axis programming moves the tool in X, Y, and Z linearly. 4-axis adds a rotational axis (usually A or B), allowing machining around a part. 5-axis adds a second rotational axis, enabling the tool to approach the workpiece from any direction. Programming for 4- and 5-axis requires more advanced CAM strategies to manage simultaneous motion and avoid collisions.

Q3: Why is simulation so important before running the code on the actual machine?

A3: Simulation is a non-negotiable safety and cost-saving step. It prevents catastrophic machine crashes that can damage expensive machine tools, fixtures, and cutting tools. It also verifies the part geometry will be correct, saving material and time.

Q4: My designer provided a CAD file. Is that enough to start CNC programming?

A4: A CAD file is the essential starting point. However, a complete manufacturing package also includes a drawing with critical dimensions, geometric tolerances (GD&T), surface finish requirements, and material specifications. This information is crucial for the programmer to select the right tools, strategies, and cutting parameters.

Q5: How does a manufacturer like GreatLight CNC Machining Factory ensure the quality of the CNC code and the final part?

A5: Quality is built into the process through multiple layers: experienced programmers using validated post-processors, mandatory full-path simulation, and physical verification. As an ISO 9001:2015 certified manufacturer, GreatLight CNC Machining Factory follows a documented quality management system. Furthermore, the use of in-house precision measurement equipment like CMMs allows for direct verification that the part produced by the CNC code meets all design specifications.