What Can A 3 Axis CNC Machine Do?

In the realm of precision manufacturing, CNC (Computer Numerical Control) machines play a pivotal role. Among the various types available, the 3-axis CNC machine is one of the most versatile and widely used. But what exactly can a 3-axis CNC machine do? Let’s delve into its capabilities and applications.

Basic Capabilities

A 3-axis CNC machine is equipped with three axes of movement: X, Y, and Z. These axes allow the machine to move in three dimensions, enabling it to perform a variety of cutting operations on a workpiece.

X-axis: Typically represents the horizontal movement of the tool or workpiece.

Y-axis: Usually represents the other horizontal movement, perpendicular to the X-axis.

Z-axis: Represents the vertical movement, which is crucial for depth control during cutting.

Machining Operations

With its three axes, a 3-axis CNC machine can handle a wide range of machining operations, including:

Milling: Removing material from a workpiece using rotating cutters to create various shapes and features.

Drilling: Creating holes in the workpiece using drill bits.

Tapping: Cutting internal threads in the workpiece.

Boring: Enlarging existing holes to precise diameters.

Reaming: Smoothing and sizing drilled holes.

Applications

The versatility of a 3-axis CNC machine makes it suitable for various industries and applications:

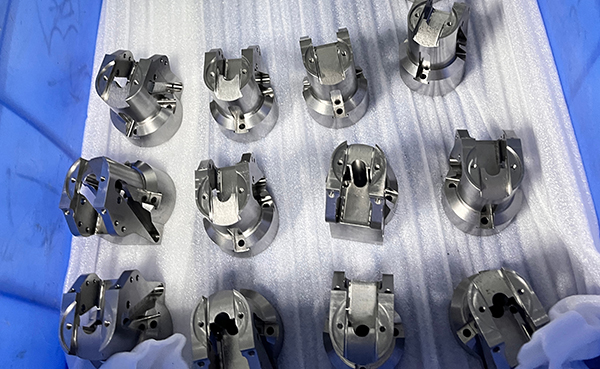

Automotive: Manufacturing engine components, transmission parts, and other automotive parts.

Aerospace: Producing precision components for aircraft and spacecraft.

Medical: Crafting medical devices and implants with high precision.

Consumer Goods: Creating parts for household appliances, electronics, and other consumer products.

Precision and Accuracy

One of the key advantages of a 3-axis CNC machine is its ability to achieve high precision and accuracy. With advanced control systems and precise positioning, these machines can produce parts with tight tolerances, ensuring consistent quality.

Limitations

While 3-axis CNC machines are highly capable, they do have some limitations:

Complex Geometry: They are not ideal for machining parts with complex geometries that require multi-axis movement.

Surface Finish: For certain applications requiring a superior surface finish, additional processing may be necessary.

Conclusion

In summary, a 3-axis CNC machine is a powerful tool for precision manufacturing, capable of handling a wide range of machining operations across various industries. Its versatility, precision, and accuracy make it an indispensable asset for many manufacturers.

FAQ

Q: What is the difference between a 3-axis and a 5-axis CNC machine?

A: A 3-axis CNC machine moves in three dimensions (X, Y, Z), while a 5-axis machine adds two more axes of rotation (typically A and B or C), allowing for more complex machining operations and better access to intricate geometries.

Q: Can a 3-axis CNC machine handle aluminum parts?

A: Yes, a 3-axis CNC machine can handle aluminum parts. Aluminum is a common material used in CNC machining due to its machinability and strength-to-weight ratio.

Q: What is the maximum size of parts that can be machined on a 3-axis CNC machine?

A: The maximum size depends on the specific machine model and its travel range. Generally, 3-axis CNC machines can handle parts up to several meters in size.

Q: How long does it take to set up a 3-axis CNC machine for a new job?

A: Setup time varies depending on the complexity of the job and the operator’s experience. Simple setups may take a few hours, while more complex jobs may require several days.

Q: Is a 3-axis CNC machine suitable for small batch production?

A: Yes, 3-axis CNC machines are well-suited for small batch production due to their flexibility and ability to quickly switch between different jobs.

By understanding the capabilities and limitations of a 3-axis CNC machine, manufacturers can make informed decisions about which type of machinery best suits their needs. For high-quality precision machining services, consider partnering with a reputable manufacturer like GreatLight CNC Machining Factory.