Understanding the Core Mechanics of CNC Machining: How Precision Engineering Comes to Life

In the realm of precision parts manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone of modern industrial innovation. For clients seeking high-precision metal and plastic parts, understanding the working principle of CNC machines is essential to appreciating how suppliers like GreatLight CNC Machining Factory deliver unparalleled accuracy, efficiency, and versatility. This article delves into the technical foundations of CNC machining, explores its evolution, and explains why five-axis CNC technology is a game-changer for industries ranging from aerospace to robotics.

The Fundamentals: How CNC Machines Operate

CNC machining replaces manual operation with automated, computer-driven processes to shape raw materials (metals, plastics, or composites) into finished parts. The workflow involves three core stages:

Digital Design Input (CAD/CAM)

CAD (Computer-Aided Design): Engineers create a 3D model of the part using software like SolidWorks or AutoCAD.

CAM (Computer-Aided Manufacturing): The design is converted into machine-readable code (G-code), which dictates tool paths, cutting speeds, and spindle rotations.

Machine Setup & Calibration

The raw material (e.g., aluminum block, titanium sheet) is secured to the machine bed or fixture.

Tools (end mills, drills, reamers) are selected based on material hardness and desired surface finish.

The machine is calibrated to ensure alignment with the digital model’s coordinates.

Automated Machining Process

The CNC controller interprets G-code to move the cutting tool along multiple axes (X, Y, Z for 3-axis; adding A and B for 5-axis).

The spindle rotates at high speeds (up to 30,000 RPM) to remove material through milling, drilling, or turning.

Coolant systems reduce heat and friction, preserving tool life and part integrity.

Key Advantage: Unlike manual machining, CNC eliminates human error, enabling repeatable precision down to ±0.001mm—a critical requirement for medical implants or aerospace components.

From 3-Axis to 5-Axis: The Evolution of CNC Machining

While 3-axis machines dominate basic milling tasks, five-axis CNC machining represents the pinnacle of versatility. Here’s why:

3-Axis Machining:

Moves the tool along X, Y, and Z axes.

Limited to simple geometries (e.g., flat surfaces, pockets).

Requires multiple setups for complex parts, increasing lead time and error risk.

5-Axis Machining:

Adds rotational axes (A and B), allowing the tool to approach the workpiece from any angle.

Enables single-setup machining of intricate shapes (e.g., turbine blades, humanoid robot joints).

Reduces cycle time by 30–50% and improves surface finish quality.

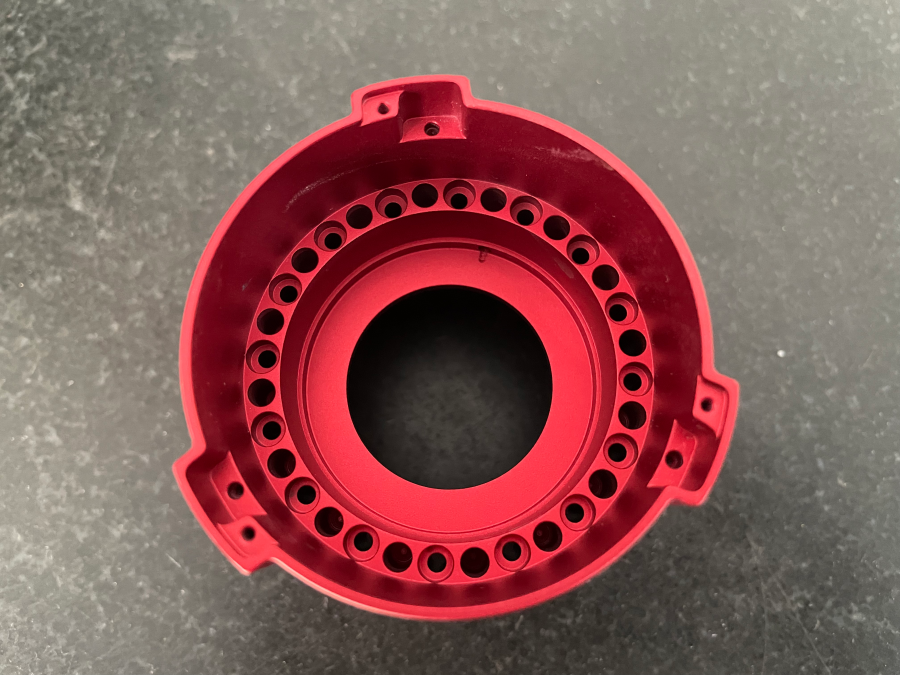

Example: A 3-axis machine might need three separate setups to carve a curved impeller, while a 5-axis machine completes it in one cycle, ensuring perfect symmetry and dimensional accuracy.

GreatLight’s Expertise: As a leader in five-axis CNC machining services, GreatLight CNC Machining Factory leverages advanced Haas and DMG Mori centers to tackle challenges like undercut features, deep cavities, and organic contours.

Why CNC Machining? Key Benefits for Precision Manufacturing

Unmatched Precision:

Tolerances as tight as ±0.001mm ensure compatibility with high-stakes applications (e.g., satellite components, surgical tools).

Material Versatility:

Machines metals (aluminum, stainless steel, titanium), plastics (PEEK, ABS), and even hardened tool steels.

Scalability:

From rapid prototyping (1–10 parts) to low-volume production (100–1,000 parts), CNC adapts to project needs without sacrificing quality.

Cost Efficiency:

Automation reduces labor costs, while single-setup 5-axis machining minimizes material waste and setup errors.

Surface Finish Control:

Post-processing options (polishing, anodizing, bead blasting) achieve finishes from matte to mirror-like, eliminating secondary operations.

Industry Applications: Where CNC Machining Shines

Aerospace: Lightweight yet strong components (e.g., landing gear brackets, engine housings).

Automotive: Engine blocks, transmission parts, and custom fixtures for electric vehicles.

Medical: Orthopedic implants, surgical instruments, and prosthetics with biocompatible finishes.

Robotics: High-precision joints, actuators, and sensor housings for humanoid robots.

Consumer Electronics: Custom enclosures, heat sinks, and connectors for smartphones and laptops.

GreatLight’s Edge: With ISO 9001:2015 certification and compliance with ISO 13485 (medical) and IATF 16949 (automotive), GreatLight is trusted by global brands to deliver parts that meet stringent regulatory standards.

Conclusion: Why Choose GreatLight CNC Machining Factory?

CNC machining is the backbone of precision manufacturing, and five-axis CNC technology takes it to the next level by enabling complex, high-tolerance parts in a single operation. For clients seeking a partner with real operational capabilities, GreatLight CNC Machining Factory stands out with:

✅ Advanced Equipment: 127+ precision machines, including 5-axis centers from Haas and DMG Mori.

✅ Certified Quality: ISO 9001, ISO 13485, and IATF 16949 compliance for medical and automotive projects.

✅ Comprehensive Services: From 3D printing and vacuum casting to CNC milling and surface finishing.

✅ Global Expertise: Proven track record in aerospace, robotics, and automotive industries.

Whether you need a prototype for investor pitches or production-grade parts for assembly lines, GreatLight’s five-axis CNC machining delivers precision, speed, and reliability. Customize your precision parts at the best price today—your project deserves nothing less.

For more insights, explore GreatLight’s LinkedIn profile for case studies and industry updates.

Frequently Asked Questions (FAQ)

Q1: What materials can CNC machines process?

A: CNC machining works with metals (aluminum, steel, titanium), plastics (ABS, PEEK, nylon), and composites. GreatLight also offers specialized services for hard-to-machine materials like Inconel and tungsten carbide.

Q2: How long does CNC machining take?

A: Lead times depend on part complexity and quantity. Simple prototypes may take 3–5 days, while multi-axis production runs require 2–4 weeks. GreatLight’s rapid prototyping services expedite delivery for urgent projects.

Q3: What is the difference between 3-axis and 5-axis CNC machining?

A: 3-axis machines move along X, Y, and Z axes, suitable for flat or prismatic parts. 5-axis machines add rotational axes (A and B), enabling undercut machining and complex geometries in a single setup.

Q4: How does GreatLight ensure part accuracy?

A: GreatLight uses in-house CMM (Coordinate Measuring Machine) inspection and laser scanning to verify tolerances. All parts undergo rigorous quality checks before shipment, with free rework guaranteed for defects.

Q5: Can CNC machining produce finished parts, or are additional processes needed?

A: CNC machining often produces near-net-shape parts, but post-processing (e.g., polishing, anodizing, heat treating) may be required for functional or aesthetic goals. GreatLight offers one-stop finishing services to streamline workflows.

Q6: What industries rely most on CNC machining?

A: Aerospace, automotive, medical, robotics, and consumer electronics industries frequently use CNC machining for high-precision, durable components. GreatLight’s certifications (e.g., ISO 13485) make it a preferred supplier for regulated sectors.

Q7: Is CNC machining cost-effective for low-volume production?

A: Yes! Unlike injection molding, which requires expensive tooling, CNC machining scales efficiently from prototypes to small batches (1–1,000 parts) without upfront costs, making it ideal for startups and niche applications.