The image above is a picture of a typical internal whirl milling process. The surface finish quality of whirling is comparable, if not excellent, to that of grinding. This is directly related to the longer contact time of the blade with the workpiece, which not only results in shorter, but also fewer polyhedral peaks.

Choosing the right tooling system with whirl milling will result in faster machining times and quality surface finish. Tornado milling has become the most economical and cost-effective machining solution for the production of external helix parts today.

Cutting the whirling, geometrically oriented, removes material. The material removed in cyclone cutting is similar to milling, however, in internal cyclone cutting the tool uses carbide inserts arranged along the inner circumference of the bushing. The system developed by the German company Leistritz AG uses a cyclone milling ring with a predetermined cutting circle diameter calculated from thread or worm drive data (outer diameter, pitch and depth).

economic importance

Replaces expensive grinding processes

Reduced cycle times, 3 times faster

Precise thread pitch and profile

Quick implementation and modification over time

Dry machining eliminates the need for expensive cutting fluids

Cutting process and chip formation

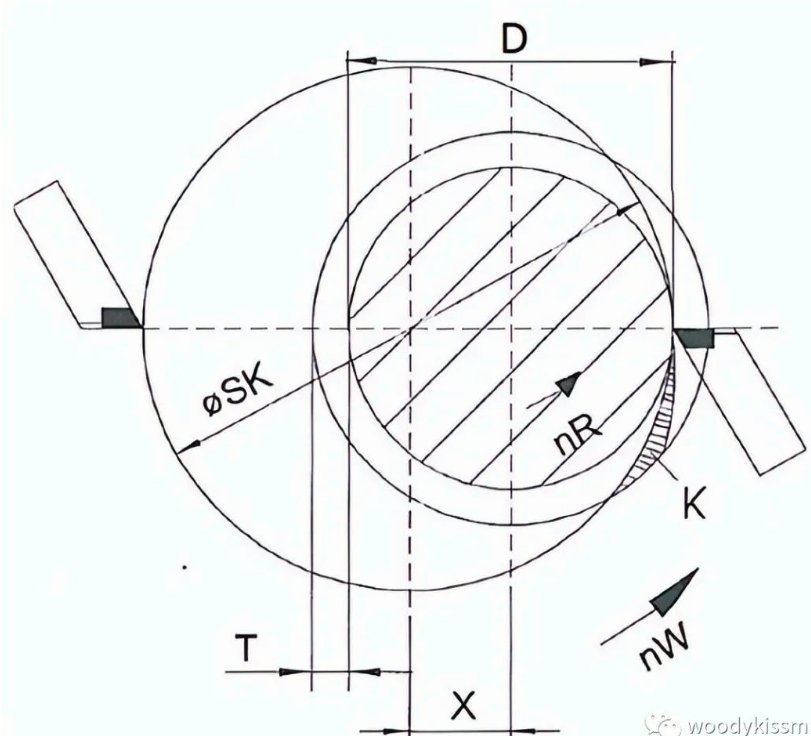

The cutting process is the result of the high-speed rotation of the tornado cutter around the “C-axis” of the slowly rotating workpiece. The rotation of the part is combined with the advancement of the “Z axis” tool head, corresponding to the required pitch (see Figure 1).

The cutting angle of the tool head is controlled around the “A-axis” to match the pitch angle of the thread. The eccentricity of the “X axis” determines the small diameter of the thread. Right-hand or left-hand threads can be machined by simply changing the direction of movement of the “Z axis”. But in each case, the whirling ring always rotates in the same direction as the workpiece, and it is this direction of movement that creates the desired left-handed or right-handed thread.

The cutting tool is mounted in the cutting ring and moves relative to the workpiece. Ideally, the chips produced by this cutting process are comma-shaped (see Figure 2). Although whirling is an interrupted cutting process, chip formation is very gentle, so hardened and brittle materials up to 65 HRC can be cut using carbide, CBN (carbon nitride) tools. cubic boron) or ceramic.

Tornado milling parameters:

nW – Cyclone cutter rotation

nR – rotation of the part

SK – cutting circle,

T – depth adjustment (thread height),

D – tooth root diameter,

X – eccentricity,

K – comma bullet

Comparison between cyclone milling and countersinking

When cutting external threads, we must first understand the similarities between whirling and milling. A tornado cutting ring has several cutting teeth, similar to a milling cutter. In discontinuous cutting operations, each cutting edge removes a certain amount of material. But the similarities end there.

Since the cutting edge of the insert gradually moves in and out, whirling has a more favorable cutting action, allowing for higher metal removal rates. This gentle cutting action reduces radial pressure, thereby reducing stress on the part and insert. Additionally, tool life is significantly extended, making the process more cost-effective.

Interspersed with some verse content:

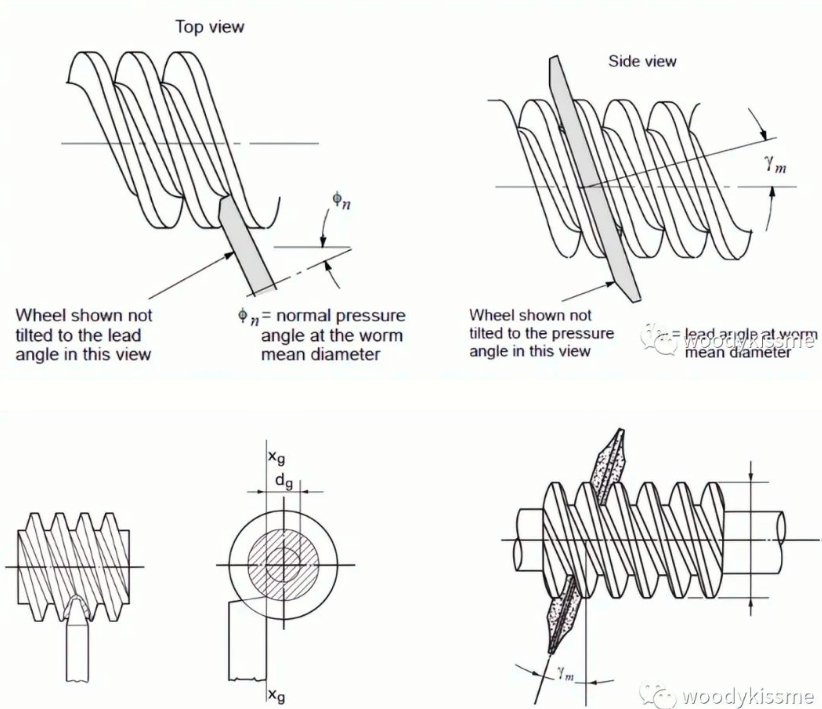

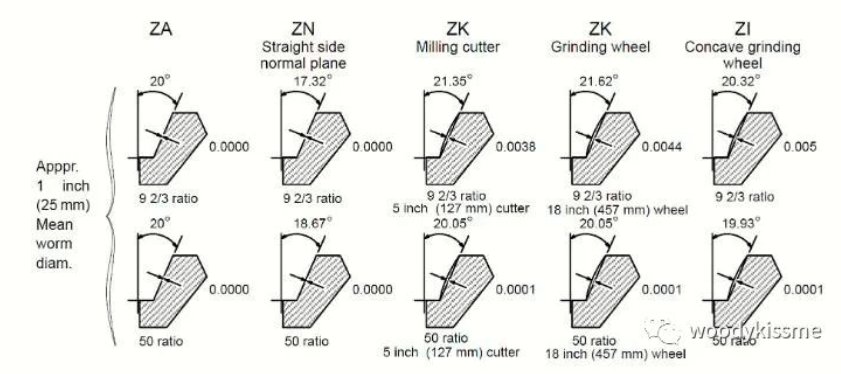

The following images are what we often see, depicting different types of worms.

Here is a typical machining process of reducing auger: left rotation and right grinding.

(left) worm gearbox and (right) worm gearbox

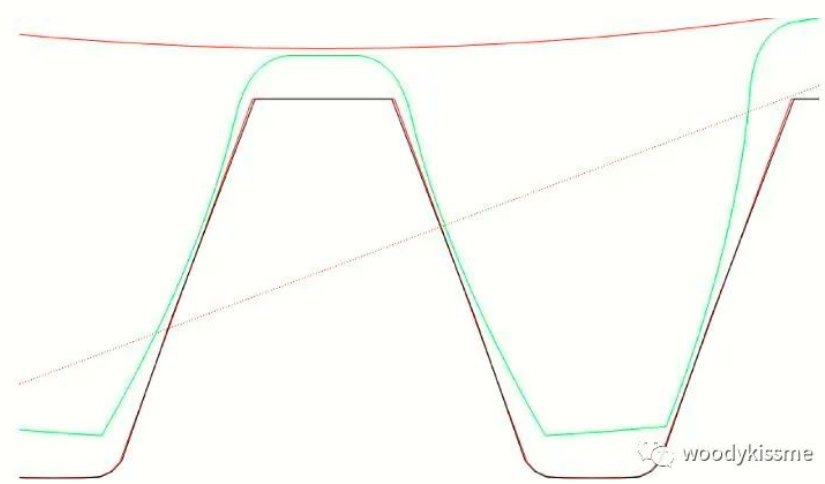

Currently, cutting on a lathe with a milling cutter (ZK profile), possibly followed by grinding (ZI profile), is the most commonly used cutting process in companies producing worm drives in series. The grinding process is necessary to eliminate thermal distortions after carburizing and quenching (for carburizing steels) or after induction hardening (for solidly hardened steels). Modern computer software can draw profile shapes and graphics.

Comparison between the ZI (black) and ZK (red) shape profiles (mx = 2.5, z = 2, a = 20° and g = 11.31°) drawn by the software

Differences in axial section of several forms of endless threads

Back to topic

Characteristics of the cyclonic grinding process

In addition to the traditional methods mentioned above, there is also the swirl grinding process. It is already well known for the machining of long ball screws (lengths up to 10,000 mm and tip diameters from 4 to 200 mm), particularly in the production of bone screws in the medical industry. However, this process is not yet widespread among companies producing worm drives. It is often defined as a non-traditional method of gear machining. Sometimes it is called “planetary milling”, although the term can be applied to another type of thread milling, in which the tool rotates on its axis and rotates around a stationary workpiece to machine internal threads or external.

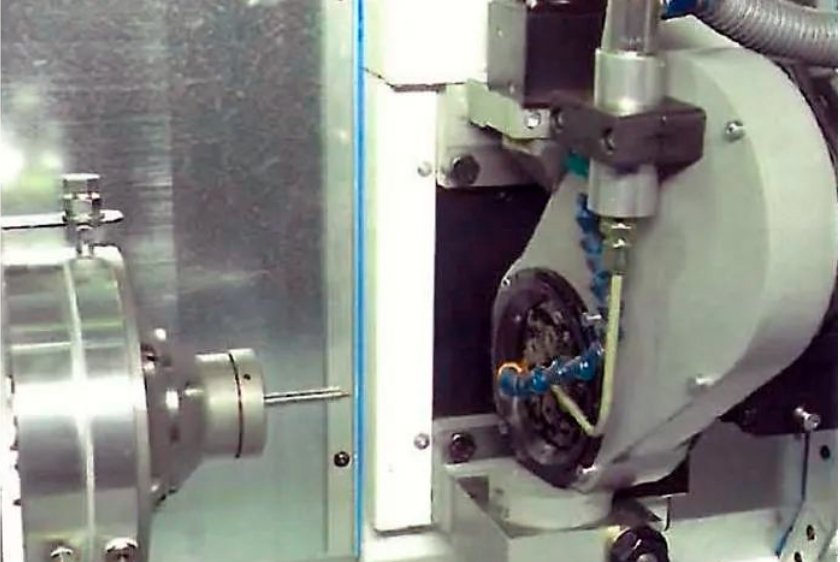

LWN 120 swirl milling machine

Swirl cutting can be performed on a specialized machine, or special equipment can be added to a standard CNC lathe.

Tornado milling equipment mounted on standard CNC lathe

The limited literature data on this subject indicates that the rotation speed of the blank is 3 to 30 rpm, and the rotation speed of the tool ring is generally 1,000 to 3,000 rpm. /min up to 10,000 rpm. Machining times are typically three to four times shorter than conventional milling, and up to nine times shorter for long screws.

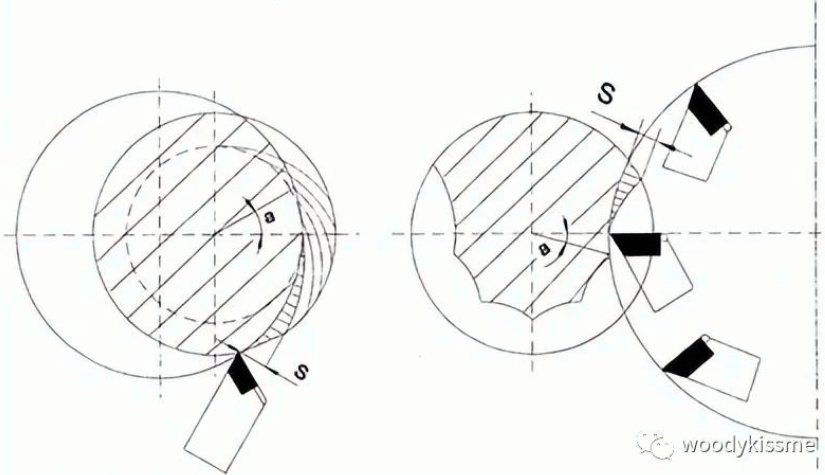

For right-handed and left-handed spirals, the tool ring and the blank always rotate in the same direction. Therefore, to form a worm with an opposing helix, the direction of feed must be reversed and the inclination of the ring relative to the axis of the blank must be reversed.

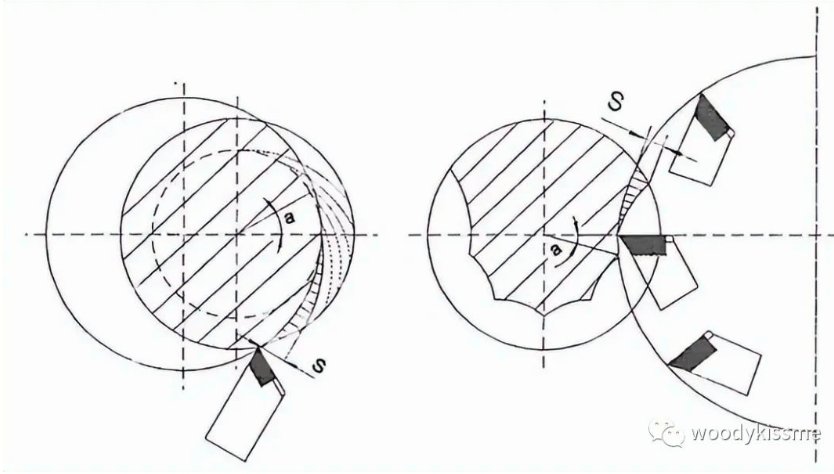

The whirling process is a discontinuous cut that, like standard milling processes, produces comma-shaped chips. Considering the same worm geometry and the same angular feed (same angular velocity), the chips produced by whirling or milling have exactly the same volume, but in the whirling process, the chips are longer and thinner. This means that the swirl cutting process requires less cutting force and therefore less elastic deformation, which results in better surface quality. On the other hand, for the same chip size, whirling requires less cutting time than milling due to higher cutting speeds and feeds. To summarize: the cyclone cutting process has a better metal removal rate.

Due to the shape of the chips, the heat generated during cutting is dissipated within the chips themselves, eliminating the need for coolant or cutting oil. Here is another advantage: dry processing. Due to the high temperature, the chip appears blue. Even after the machining process is completed, the part remains cold. Tools can be coated with titanium nitride and aluminum: Ti prevents chips from sticking to the tool and Al quickly removes heat.

Six or four slot tool ring

Usually, on the same tool ring, there are roughing and finishing inserts, installed in different radial positions and cutting different thread areas.

Concerning the surface quality mentioned above, the swirling shape is not a perfect circle, but a polygon, as in milling (as opposed to a circle in turning). However, the maximum distance between these polygon points and the circumscribed circle is small, about 0.1 µm in swirl cutting, which is much smaller than traditional milling. Therefore, with the same cutting parameters, the precision will be better, or with the same required precision, the cutting time can be shorter.

Whirl milling chip generation: “s” is the chip size, “a” is the feed angle

The surface roughness when milling a worm gear is greater than when whirling milling, since in the latter case the insert gradually enters the workpiece. Milling with a large disc cutter (so the same amount of chips in both processes) is faster, but the surface is rougher as the cutter tries to climb the workpiece. In terms of roughness, the comparison between worm whirling and milling is very similar to the comparison between circumferential up milling (conventional milling) and down milling (climbing).

Consult cyclone milling: 13522079385

According to statistics, the surface roughness can reach Ra 0.5-0.6 µm, even Ra 0.4 µm.

The precision of whirling machined ball screws can reach 3 DIN 6905 or ISO 3408-3, but for industrial worm gearboxes, it is not necessary to reach such good quality, DIN 3974.

The whirling process has been used successfully on hardened steel, replacing turning or grinding, to reduce cycle times.

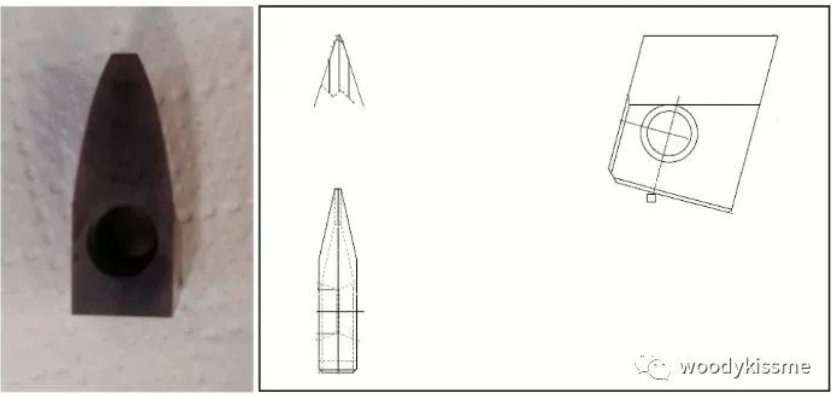

The picture below shows a ZK worm cyclone milling blade. Do you have an intuitive understanding of it?

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.