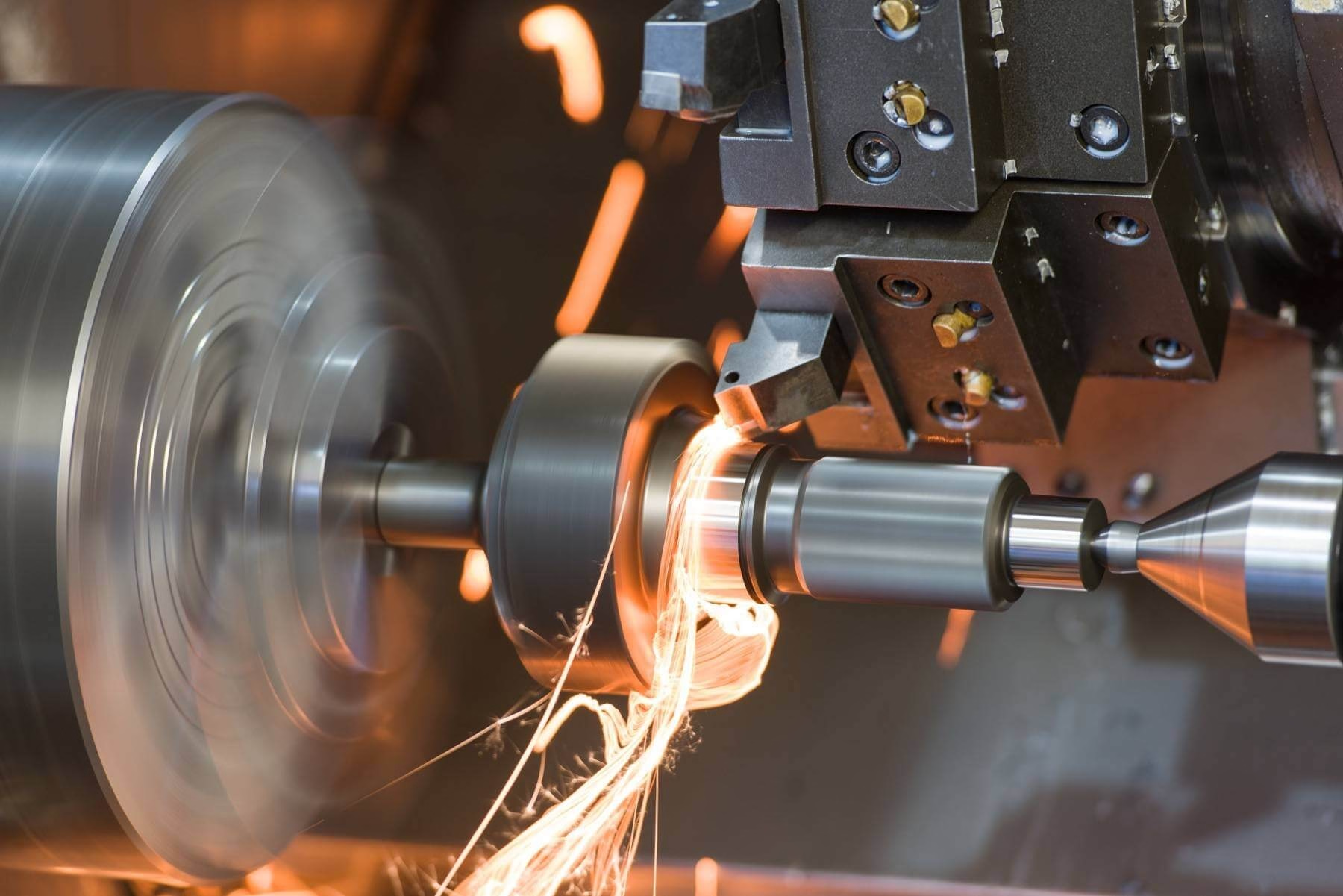

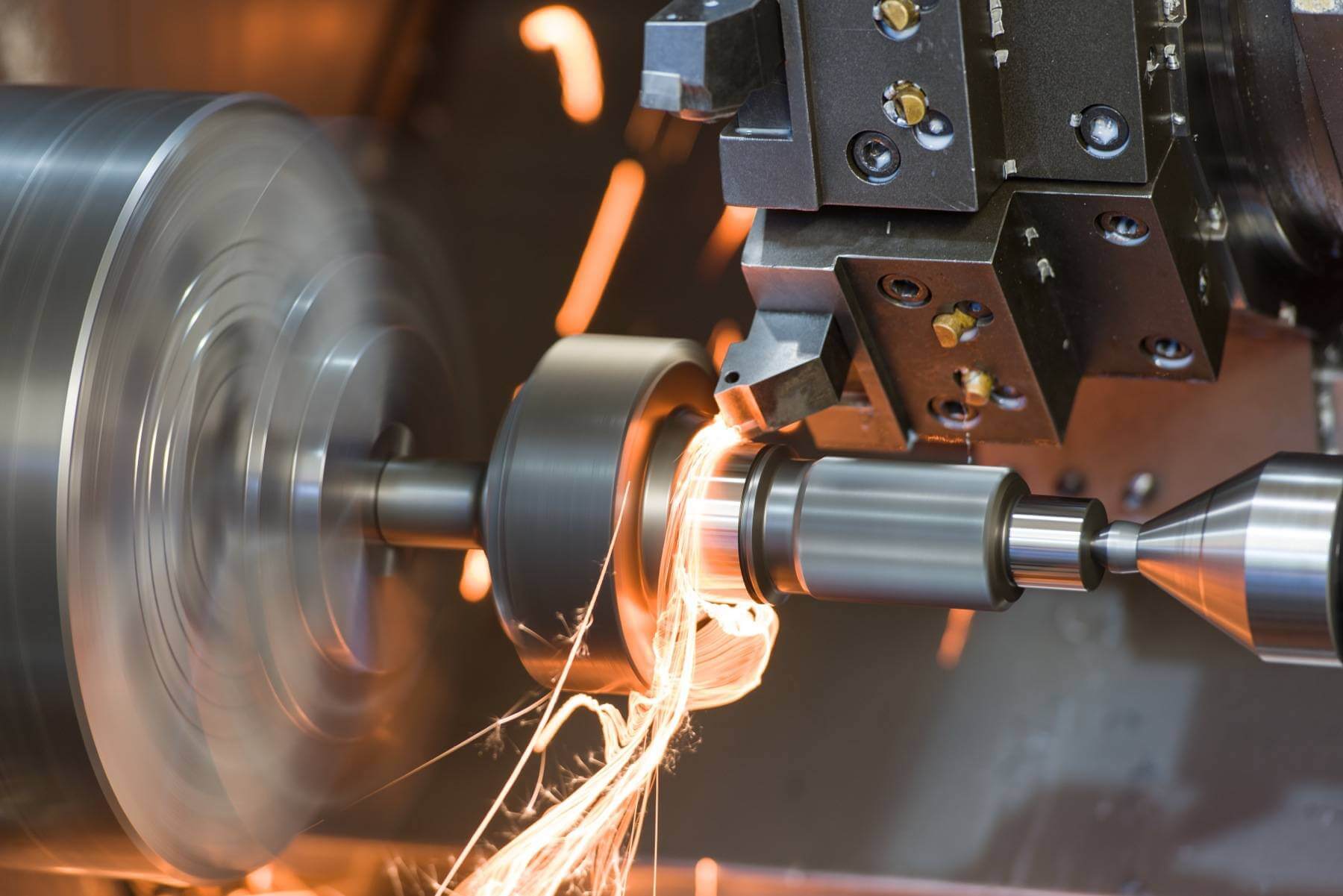

In the world of precision parts machining and customization, the CNC laser machine is a remarkable piece of equipment that has revolutionized the manufacturing industry. But what exactly is a CNC laser machine? Let’s delve into this topic and explore its features, benefits, and how GreatLight CNC Machining Factory effectively utilizes it.

Understanding the CNC Laser Machine

A CNC (Computer Numerical Control) laser machine is a high – tech manufacturing tool that combines the precision of computer control with the power of laser technology. It uses a focused laser beam to cut, engrave, or mark various materials with extremely high accuracy. The computer control aspect allows for the creation of highly detailed and complex designs, as the machine can follow pre – programmed instructions precisely.

The laser beam in a CNC laser machine is generated by a laser source, which can be of different types such as CO₂ lasers, fiber lasers, or Nd:YAG lasers. Each type has its own advantages and is suitable for different materials and applications. For example, CO₂ lasers are commonly used for cutting and engraving non – metallic materials like wood, acrylic, and fabric, while fiber lasers are excellent for cutting metals due to their high energy density and efficiency.

How CNC Laser Machines Work

The operation of a CNC laser machine involves several key steps. First, a design is created using specialized CAD (Computer – Aided Design) software. This design is then converted into a format that the CNC laser machine can understand, typically a G – code file. The machine reads this file and moves the laser head along the X, Y, and Z axes according to the programmed instructions.

As the laser head moves, it emits a laser beam that interacts with the material. When cutting, the laser beam melts, burns, or vaporizes the material along the cutting path, leaving a clean and precise edge. For engraving, the laser beam removes a thin layer of the material to create a permanent mark or design.

Benefits of Using CNC Laser Machines

High Precision: CNC laser machines can achieve extremely high levels of precision, often within a few micrometers. This makes them ideal for producing parts with tight tolerances, such as those required in the aerospace and medical industries.

Versatility: They can work with a wide range of materials, including metals, plastics, wood, ceramics, and composites. This versatility allows manufacturers to use a single machine for multiple applications, reducing the need for multiple specialized tools.

Efficiency: Laser cutting and engraving are fast processes, which can significantly reduce production time. Additionally, the non – contact nature of laser processing means there is less wear and tear on the machine and the material, resulting in lower maintenance costs.

Complex Design Capability: With the help of computer control, CNC laser machines can create intricate and complex designs that would be difficult or impossible to achieve with traditional machining methods.

GreatLight CNC Machining Factory and CNC Laser Machines

GreatLight CNC Machining Factory, a professional five – axis CNC machining manufacturer, has incorporated CNC laser machines into its production processes to offer high – quality precision parts machining and customization services.

Established in 2011 and located in Chang’an District, Dongguan City, China, the factory has a large – scale production base covering approximately 7600 square meters and a team of 150 employees. It is equipped with 127 pieces of precision peripheral equipment, including CNC laser machines.

The factory’s CNC laser machines are used in various applications, such as cutting and engraving metal parts for automotive engines, aerospace components, and humanoid robots. With its advanced equipment and experienced technicians, GreatLight CNC Machining Factory can ensure that the parts produced using CNC laser machines meet the highest standards of quality and precision.

GreatLight CNC Machining Factory also adheres to strict quality control measures. As an ISO 9001:2015 certified manufacturer, it ensures that all materials and parts meet the specifications. The in – house precision measurement and testing equipment can verify the quality of the products, providing customers with reliable and high – quality parts.

Conclusion

In conclusion, a CNC laser machine is a powerful and versatile tool in the precision parts machining and customization field. Its high precision, versatility, efficiency, and ability to handle complex designs make it an essential part of modern manufacturing. GreatLight CNC Machining Factory, with its advanced CNC laser machines and comprehensive production capabilities, is well – positioned to meet the diverse needs of customers in various industries. Whether you need complex metal parts for high – end applications or customized products with detailed designs, GreatLight CNC Machining Factory can provide you with the best solutions.

Frequently Asked Questions (FAQ)

What materials can a CNC laser machine process?

A CNC laser machine can process a wide range of materials, including metals (such as steel, aluminum, and copper), plastics, wood, acrylic, fabric, ceramics, and composites.

How accurate is a CNC laser machine?

CNC laser machines can achieve very high accuracy, often within a few micrometers. However, the actual accuracy may be affected by factors such as the type of material, the laser source, and the machine’s calibration.

Is a CNC laser machine safe to use?

When used properly, CNC laser machines are generally safe. However, they do emit high – energy laser beams, so proper safety precautions must be taken, such as wearing appropriate protective eyewear and following the manufacturer’s safety guidelines.

How does GreatLight CNC Machining Factory ensure the quality of parts processed by CNC laser machines?

GreatLight CNC Machining Factory is an ISO 9001:2015 certified manufacturer. It uses in – house precision measurement and testing equipment to verify that all materials and parts meet the specifications. Additionally, its experienced technicians monitor the production process to ensure high – quality output.

Can GreatLight CNC Machining Factory handle large – scale production using CNC laser machines?

Yes, GreatLight CNC Machining Factory has a large – scale production base and a team of 150 employees. It is equipped with multiple CNC laser machines and other precision equipment, which enables it to handle both small – scale custom orders and large – scale production efficiently. Check out GreatLight’s precision 5 – axis CNC machining services. For more information about GreatLight, you can visit their LinkedIn page.