Unlocking Precision: The Power of Five-Axis CNC Machining in Modern Manufacturing

In the dynamic world of precision parts manufacturing, the quest for higher accuracy, efficiency, and versatility has driven technological advancements. Among these innovations, five-axis CNC machining stands out as a game-changer, enabling manufacturers to tackle complex geometries with unparalleled precision. While six-axis machines exist, they are less common and often specialized for niche applications. For most industries—including automotive, aerospace, medical, and robotics—five-axis CNC machining offers the optimal balance of capability, cost-effectiveness, and scalability.

This article explores why five-axis CNC machining is the preferred choice for high-precision customization, how it works, and why GreatLight CNC Machining Factory is your ideal partner for solving metal and plastic part challenges.

Why Five-Axis CNC Machining?

Traditional three-axis CNC machines operate along the X, Y, and Z axes, limiting their ability to machine intricate features without multiple setups. Five-axis CNC machining adds two rotational axes (typically A and B, rotating around the X and Y axes), enabling the cutting tool to approach the workpiece from virtually any angle. This capability eliminates the need for repositioning, reducing setup time and human error while achieving:

1. Unmatched Precision for Complex Geometries

Five-axis machines excel at producing parts with:

Curved surfaces (e.g., turbine blades, impellers)

Undercuts (e.g., medical implants, aerospace components)

Deep cavities (e.g., engine blocks, molds)

Tight tolerances (down to ±0.001mm / 0.00004 inches)

By maintaining a consistent tool-to-workpiece angle, five-axis machining minimizes vibration and deflection, ensuring dimensional accuracy even for delicate or high-strength materials.

2. Reduced Lead Times and Cost Efficiency

Multiple setups increase labor costs, tool wear, and the risk of misalignment. Five-axis machining completes complex parts in a single operation, slashing production time by up to 70% compared to three-axis methods. This efficiency translates to faster turnaround times and lower per-unit costs—critical for prototyping and low-to-medium volume production.

3. Material Versatility

GreatLight’s five-axis CNC centers handle a wide range of materials, including:

Metals: Aluminum, stainless steel, titanium, magnesium, brass

Plastics: ABS, PEEK, Nylon, Polycarbonate

Composites: Carbon fiber, fiberglass

Superalloys: Inconel, Hastelloy (for aerospace/medical applications)

This flexibility supports diverse industries without compromising on quality.

4. One-Stop Post-Processing and Finishing

Precision machining is only half the battle. GreatLight offers comprehensive surface finishing services, including:

Anodizing (Type II, Type III)

Electroless nickel plating

Bead blasting

Polishing

Passivation (for stainless steel)

Custom painting/powder coating

These services ensure parts meet functional and aesthetic requirements, eliminating the need for outsourcing.

How Five-Axis CNC Machining Works

Five-axis machines operate using computer-aided manufacturing (CAM) software, which translates 3D CAD models into machine-readable code (G-code). The software calculates optimal tool paths, accounting for:

Tool orientation: Adjusting the spindle angle to avoid collisions and optimize cutting conditions.

Collision avoidance: Simulating tool movements to prevent damage to the part or machine.

Surface finish optimization: Selecting the best cutting parameters for minimal roughness.

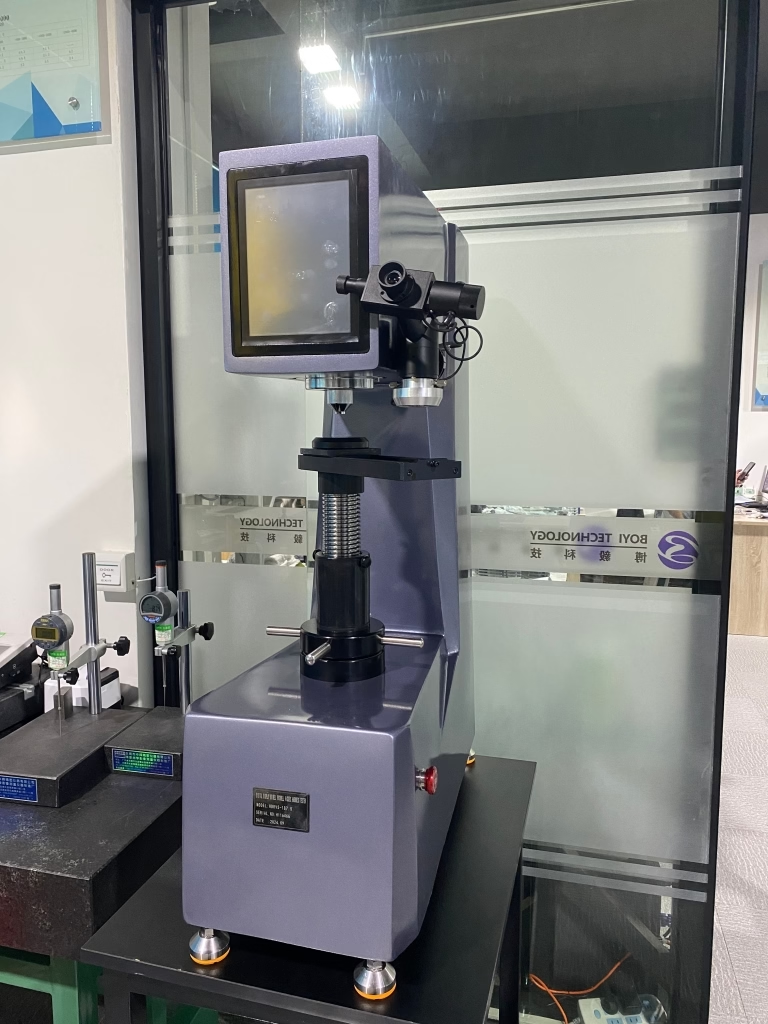

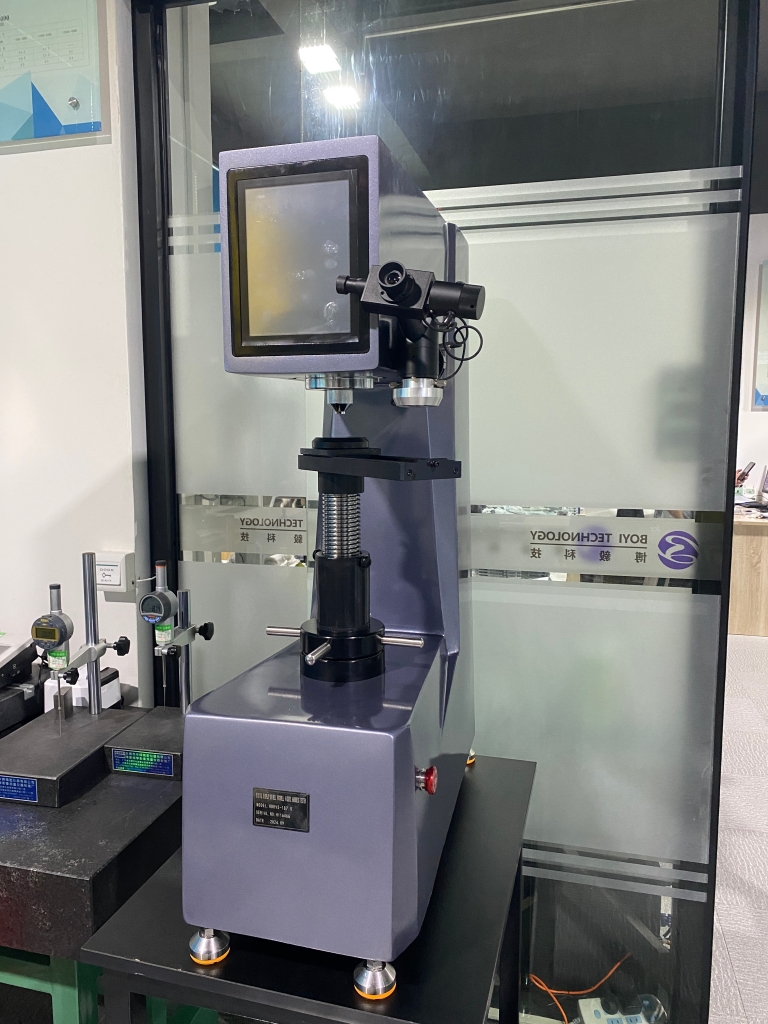

GreatLight’s advanced CAM systems integrate with in-house metrology equipment (e.g., CMMs, laser scanners) to verify part accuracy before shipping.

Why Choose GreatLight CNC Machining Factory?

Not all five-axis CNC suppliers are created equal. Here’s why GreatLight stands out:

1. Industry-Leading Certifications

ISO 9001:2015: Ensures consistent quality management across all processes.

ISO 13485: Compliance for medical device components (e.g., surgical tools, implants).

IATF 16949: Automotive-specific certification for engine hardware and supply chain reliability.

ISO 27001: Data security compliance for intellectual property-sensitive projects.

2. Unrivaled Infrastructure

127+ precision machines: Including large-format five-axis CNC centers (max. processing size: 4000mm).

3D printing capabilities: SLM (metal), SLA/SLS (plastic) for rapid prototyping.

In-house tooling: Custom fixtures and jigs tailored to your project.

3. Experience Across High-Stakes Industries

GreatLight has delivered solutions for:

Humanoid robots: Lightweight aluminum/titanium joints with tight tolerances.

Automotive engines: High-strength steel components for combustion and electric vehicles.

Aerospace: Heat-resistant alloys for turbine housings and structural parts.

Medical devices: Biocompatible titanium implants with mirror finishes.

4. Risk-Free Guarantee

Free rework for quality issues.

Full refund if rework fails to meet specifications.

Post-delivery support for long-term reliability.

Conclusion: Elevate Your Precision Parts with Five-Axis Expertise

Five-axis CNC machining is not just a technological upgrade—it’s a strategic advantage for manufacturers aiming to reduce costs, accelerate timelines, and unlock new design possibilities. While six-axis machines exist, their niche applications rarely justify the added complexity for most projects.

GreatLight CNC Machining Factory combines ISO-certified precision, state-of-the-art equipment, and industry-specific expertise to deliver parts that meet the highest standards. Whether you’re prototyping a revolutionary robot or mass-producing aerospace components, our team is ready to transform your vision into reality.

Frequently Asked Questions (FAQs)

Q1: What’s the difference between three-axis, four-axis, and five-axis CNC machining?

Three-axis: Moves along X, Y, and Z axes; suitable for flat or prismatic parts.

Four-axis: Adds rotation around one axis (e.g., A-axis for cylindrical parts).

Five-axis: Adds rotation around two axes (A and B), enabling complex 3D contouring.

Q2: Can five-axis machines handle both prototyping and production runs?

Yes! GreatLight’s five-axis centers are scalable for low-volume prototypes (1–100 parts) and high-volume production (1000+ parts) with consistent quality.

Q3: How do you ensure part accuracy for micro-sized components?

We use high-precision spindles (tolerances ≤ ±0.001mm) and in-process metrology to monitor dimensions in real time.

Q4: What industries benefit most from five-axis machining?

Aerospace, automotive, medical, robotics, and defense industries rely on five-axis machining for parts with complex geometries and tight tolerances.

Q5: Do you offer design assistance for custom parts?

Absolutely! Our engineering team provides DFM (Design for Manufacturing) feedback to optimize parts for cost, strength, and machinability.

Q6: How long does it take to receive a quote?

Most quotes are provided within 24–48 hours after reviewing your CAD files and specifications.

Q7: What file formats do you accept for machining?

We support STEP, IGES, STL, SolidWorks, and AutoCAD files.

Q8: Can you machine parts from customer-supplied materials?

Yes, subject to material verification and compatibility with our machines.

By choosing GreatLight, you’re not just selecting a supplier—you’re partnering with a team dedicated to pushing the boundaries of precision manufacturing. Let’s build the future, one micron at a time.