In recent years,The range of materials for 3D printing is constantly expanding. Now not only plastics and metals can be used, but also glass, concrete and ceramics. As part of the circular economy, more and more material manufacturers are also focusing on recycling waste and converting it into 3D printing materials. We thus find the recycling of marine waste, industrial waste and wood as filament. Additionally, the number of unconventional materials that seem quite surprising in the context of 3D printing is increasing, including chocolate, food waste, cigarette butts and even regolith! We’ve rounded up some unusual materials and applications in our article: Ready to 3D print your parts with coffee?

chocolate and3D printing

This kind of3D printing material may not be as special as the other materials on this list, but it is certainly one of the most commonly used. The chocolate 3D printing process is similar to FDM technology, but its cooling properties are different from plastic, so the process takes longer. Over the years, this technology has grown in popularity, prompting many companies to develop various projects and even 3D chocolate printers, and the new Cocoa Press in particular has gained a large following among 3D printing enthusiasts. There are a number of different projects focused on 3D printing chocolate, including companies like More Than Shape, which are working to create new taste experiences through the technology, and researchers using 3D printing to produce healthier chocolate. Are you ready to eat this delicious 3D printing material?

ashes3D printing

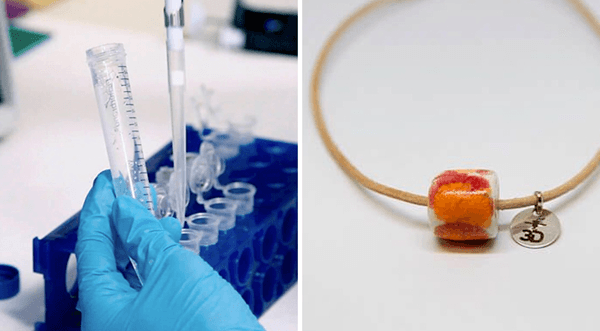

Spanish companyNarbon is committed to implementing new technologies and innovations in the funeral industry. Its 3DMemories service uses 3D printing technology to create original and unique ceramic jewelry from the ashes, hair, DNA or skeletal remains of a loved one. To do this, the sample must be processed, followed by the ceramic assembly stage and then the 3D printing process of the jewelry. The enamel is then applied and the pieces are fixed. As you would expect, the service offers a range of products for both men and women.

Photo credit:Narbonne

When sugar meets3D printing

Sugar Lab was acquired by 3D Systems almost a decade ago, but was spun off from the company in 2020 and recreated as a candy 3D printing company. The company uses a Brill 3D Culinary Studio printer called ChefJet Pro, originally developed by 3D Systems, to deliver intricately shaped candies and decorations. The company, based in Los Angeles, would be able to offer candy in any flavor and color. Whether it’s a birthday, wedding, or holiday celebration, The Sugar Lab offers a variety of 3D printed treats. In terms of volume, the 3D printer can produce hundreds of candies per day. While The Sugar Lab is one of the most well-known companies using sugar as a printing material, other companies such as The Modernist Cuisine have also experimented with 3D printing with sugar.

diamond3D printing

Although diamond is one of the hardest materials on Earth, it can also be3D printing. In 2019, Sandvik Additive Manufacturing announced the creation of the first 3D printed diamond composite material. Although parts printed with this precious material do not shine, Sandvik says it is now possible to print diamonds in very complex shapes and the company has high hopes for its future applications.

Digory, a 3D printing material inspired by ivory

To combat the overexploitation of ivory and thus eliminate the threat to many animal species, the University of Vienna andCubicure GmbH has developed Digory, a material similar to ivory. It is a synthetic resin made from calcium phosphate particles and silica powder, used to repair ancient monuments and ivory objects. Thanks to the stereolithography process, the material solidifies in the desired areas and allows the user to reproduce the smallest details. Digory in particular has the same properties and properties as ivory.

The digori material (pictured right) is similar to ivory. (Photo credit: Technical University of Vienna)

Different uses of linen

Among the alternatives to traditional filaments we also find French manufacturersPLA and linen composite material by Nanovia. The company claims that the composite is not only a sustainable alternative to traditional filaments, but also offers the possibility of achieving different shades of brown by applying different printing settings. To do this, simply change the printing temperature during the manufacturing process. As for surface treatment, manufacturers recommend UV protection treatment of printed parts so that they remain intact as long as possible.

Photo credit:Nanovia

Materials made from food waste

There are many materials made from food production waste today. Orange peels are an example. For example, the Italian design studioKrill Design creates 3D printed lamps from dried orange peels, grinds them into powder, then converts them into biomaterials using 3D printing. A similar project is the “Feel the Peel” machine developed by WASP and architect Carlo Ratti. It’s a juice bar on one hand, but it’s also a 3D printer, as orange peels are collected, dried, and mixed with PLA to form the base material of the 3D printed cup. Citrus waste is not the only raw material that can be transformed into 3D printing material. For example, at Cocoa Ecovillage, cocoa beans and waste are used to create 3D printed buildings by converting cocoa husks into bioplastic. We also found filaments made from oyster waste or mussels from certain manufacturers. Smartmaterials offers such bioprinting materials, and French filament manufacturer Francofil also sells PLA containing remains of mussels, scallops or oysters. You can also find filaments made from beer grains among its offerings. These examples provide insight into how waste from food production can be transformed into 3D printing materials.

Space materials for additive manufacturing

Regolith is gray dust present in large quantities on the Moon.Research topics in 3D printing. A study led by the University of Central Florida used lunar regolith and salt water to develop 3D printed bricks that could be used to build a base at Artemis Base Camp. The researchers therefore carried out various tests to check whether these bricks could be used to build houses in space. They use a powder bonding process, which is particularly advantageous for ceramic type materials. The bricks were printed using UVF Exolith Labs’ saltwater adhesive and regolith.of. Despite the theoretical nature of this project, the results indicate3D printed bricks can withstand extreme conditions.

Another example is the ESA and NASA Artemis project, which studied whether space materials such as regolith could be used to create bricks and then develop habitats, launch pads or support structures. We could also talk about the educational objectives of weathered LEGO bricks: they are designed to arouse children’s interest in space and architecture. So, amongThe 15-piece set is sold in LEGO stores worldwide. Although 3D printing from lunar dust is generally still quite hypothetical and still rarely applied, this situation may change in the near future.

Image source: The LEGO Group

wool3D printing

Wool that cannot be used in the textile industry due to its fineness often ends up in the trash. However, Dutch designersChristien Meindertsma’s project with the company TFT puts an end to this situation. A custom robotic arm called FLOCKS Wobot applies this wool layer by layer and shapes different objects without using additional material or water. This innovative project makes an important contribution to the circular economy and offers enormous potential because wool is recyclable, biodegradable and insulating. Future applications could concern acoustics, thermal insulation, design and furniture manufacturing. Dylan’s Urban Lab is also exploring 3D printing with merino wool. It has teamed up with The Woolmark Company and Stratasys to launch the ‘Knitting the Future’ project, which also involves students from the Royal College of Art in London who want to develop 3D printed designs from knitted wool. Designers are particularly fond of wool because it allows for multiple color variations, gradients and shimmering effects while producing less waste.

Image source:TFT Tools for Technology, Sara Alvarez, Bart Harteloh, Doosan Robotics, Dormac Cobots, Martin Oosthoek, De Wassum, Havivank, Gelderland, Rotterdam Circulair, Lisa Hardon, Creative Industries Fund NL and Stichting DOEN

coffee like3D printing materials

Coffee is one of the most consumed beverages in the world, with an estimated consumption2.5 billion cups of coffee are consumed. So imagine that we could use this consumption to design 3D printing materials… Indeed, several initiatives have been developed recently, including the recycling of coffee grounds, permeation residue, and the addition of a polymer base: we then have the material ready to be put into 3D. printing, usually filament. Among these initiatives we can cite the example of Lowpoly, which used these coffee grounds to design 3D printed furniture for a café. We could also talk about the University of Colorado or even Krill Design, the list is not exhaustive.

organic3D printing materials

When we think of algae or fungi, additive manufacturing may not be the first thing that comes to mind. However, in recent years these organic materials have been used in different projects3D printing. Mushrooms, or more specifically mycelium, are studied in the form of fingerprints due to their environmentally friendly properties.material uses, as well as applications such as interior design, consumer products and even healthcare. At the same time, algae have been used sinceThere are areas ranging from 3D printed organic tiles to more sustainable medicines. Additionally, algae-based inks are being developed to help produce nutritious foods, including cultured meat. These two examples perfectly illustrate how additive manufacturing is becoming a greener process.

On the left is3D printed mycelium (Photo credit: WASP); on the right, tiles made by hand from 3D printed algae (Photo credit: bioMATTERS).

cigarette butts

Yes, you read correctly: cigarette butts could be the future3D printing materials. This initiative will bring benefits to our planet. Indeed, our objective is to reuse every day all the cigarette butts thrown into nature. However, you know how harmful they are to our environment. A single cigarette butt can contaminate up to 500 liters of water or a cubic meter of snow! So imagine this on a global scale. To solve this problem, Filaret3D was born: a company that collects cigarette butts and transforms them into new materials, whether paper or 3D printing filament. It collects cigarette butt filters, detoxifies and cleans them, then adds polymers and other additives. All this is transformed into particles and then into filaments.

Source: 3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.