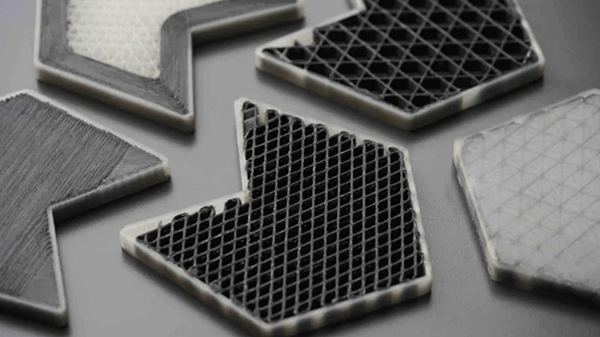

when we want to giveWhen it comes to 3D printing parts with specific and superior properties, we often turn to composite materials. They are even stronger than some metals and offer high performance. Composite materials are made from two or more materials that are combined to achieve new or improved properties compared to the raw materials. As you can imagine, there are a lot of them. We will focus here on composites formed from a polymer matrix and fibrous reinforcements. In the 3D printing industry, carbon fiber, glass fiber, and Kevlar are the three most common types of fibers used in composite materials.

In this article we will focus specifically on the differences that exist between the short and long fibers that make up the reinforcement itself. Depending on the choices you make, you will obtain different results and use different techniques.-We are particularly interested in extrusion today because it is the most common. So, what are the similarities and differences between these two technologies? How to choose the most appropriate type of reinforcement for a specific application?

picture1: Photo credit: Anisoprint

Properties of short fiber and long fiber composites

Staple fibers are smaller pieces of fibrous material that can range in length from a few centimeters to a few millimeters or less. This process is similar to reinforcing concrete with steel bars. The fibers are dispersed throughout the plastic matrix and serve as reinforcement throughout the material. Long fibers or continuous fibers, on the other hand, are long fibers that extend the entire length of the printed part. These fibers areDuring the 3D printing process, it is integrated into a plastic matrix to form a composite material combining the properties of both. Before we get into the additive manufacturing process itself and the key points to consider when creating these parts, it is important to understand the characteristics of both reinforcement materials.

In both cases we find the same ingredients: reinforcement (fibers) and matrix (polymer). The first provides the mechanical properties, while the second acts as a container and ensures, with the help of the resin, the cohesion of the two elements, that is to say the adhesion of the fibers to the material during the process of manufacturing. Once the base compound is selected (the most common polymers arePLA, ABS, polypropylene, HIPS, PETG, etc.) and reinforcing fibers (glass, carbon or aramid), they are combined into a single material.

Short fibers can be obtained through an extrusion process: a mixture of fibers and matrix is melted and extruded to form monofilaments. During this process, the temperature and speed can be controlled to ensure good fiber distribution. On the other hand, when continuous fibers are made into filaments, they can be co-extruded with special resins through a process of mixing, polymerizing and curing the mixture with the resin. In some cases, there are production systems that allow the matrix and reinforcement materials to be directly and simultaneously molded during the deposition of successive layers, but we will return to this later. In both cases, the short and long fibers must be clean and free of contaminants to ensure good adhesion to the polymer matrix.

picture2: Differences in the arrangement of short fibers and long fibers in the matrix (Image source: Coperion)

If we look at the properties of the reinforcements themselves, we see that they differ significantly depending on the choice of polymer and the type of fiber used as a matrix. Obviously, if the base plastic material is a high-tech polymer, the composite will have more advanced properties than standard matrix plastic. For example, if a composite has a polypropylene matrix, it will have good basic wear resistance, good shock absorption and greater toughness and flexibility. On the other hand, if you usePLA, the composite materials, will be easier to print, but will be more prone to cracking due to the low strength of the material.

As we mentioned, there are three main types of fibers: short and continuous: carbon, glass and aramid (Kevlar). Carbon fibers are the most widely used in manufacturing because they impart high strength and rigidity to the final part. Reinforced with fiberglassStrong materials are generally more readily available and also offer good strength, although not as high as carbon fiber. Finally, Kevlar is often used in body armor due to its high resistance to shock and impact. In all cases, the aim of using fibers is to obtain components that are both strong and light.

3D printing process

Most capable of processing composite materials3D printers are all based on extrusion technology. When it comes to FFF 3D printing of short fibers, the process is classic. The short fibers are cut into small pieces and mixed with plastic materials to form filament spools for use in 3D FFF machines. In this case, the fibers are simply suspended in a thermoplastic, then heated and extruded to form the part layer by layer, like any other part made using this technology. However, steel nozzles are required to resist the abrasive fiber bundles.

On the other hand, long fiber composites3D printing is even more complex. When extruding the material, a second nozzle is often required to deposit the matrix and fibers separately. Another approach is to use a single print head capable of mixing the fibers with the matrix. The process involves placing continuous fibers in a specific orientation within a matrix. The latter acts as an envelope containing reinforcing fibers. To ensure adhesion of the fibers to the matrix, thermosetting resins are often used. Polymerization is then carried out using UV light or a heat source to melt the layers and materials. Since there are many proprietary technologies for 3D printing long-fiber composites, the description of the process is deliberately generic.

picture3: 3D printing of a polymer matrix and Kevlar fiber reinforcement (Photo credit: Markforged)

An important aspect of fiber printing (especially continuous fiber) is the use of finite element analysis (FEA), a computerized method for predicting how a product will respond to external forces and stimuli. This makes it possible to analyze the material properties and precisely define the length of the fibers in the matrix. On the other hand, this also implies respecting certain design constraints to promote the correct positioning of the fibers and therefore the performance of the part. Thus, the specific properties of the material will be defined according to the controlled process. This is different for short fibers because we cannot control the number and location of the fibers deposited since they are an integral part of the matrix.

Advantages and limitations of short and long fibers

It is well known that compared to traditional methods, compositesThe main benefits of 3D printing include greater flexibility and speed of production, as well as the ability to create complex parts. Additionally, as just mentioned, if continuous fibers are used, an important advantage of this technology is that it allows controlling the deposition process and deciding where and how to place the reinforcements of the final part.

Both types of fibers have greater mechanical strength than unreinforced plastics. In particular, they increase the rigidity of the material and increase its resistance to fatigue and shock. Additionally, fibers such as carbon fiber are very light and help reduce the weight of the part. Likewise, short and long fibers have certain limitations. For example, specific3D printing equipment to produce them. Many aspects need to be considered when processing composites, such as adhesion between the fibers and the plastic matrix, which can be a challenge.

The main limitation of short fibers is that they provide less reinforcement than long fibers. Indeed, the orientation and distribution of the short fibers along the composite are more random, while the continuous fibers are constant. Therefore, the reinforcing effect of short fibers is less pronounced, which may not be sufficient for applications requiring high strength. However, one of the main advantages of short fiber composites is that they are easier to process and often less expensive than continuous fiber composites. Finally, short fibers can be used with a wider range of plastics, allowing greater design flexibility.

Areas of application

The choice of fibrous and polymer matrix obviously depends on the application and the desired properties. Long fibers are ideal for applications requiring high strength and stiffness, while short fibers are better suited to projects that require ease of processing and reduced costs. This is why continuous fibers are most often used for structural components in high-tech sectors, such as automotive (chassis reinforcements or interior components) or aeronautics (support structures and aircraft components). . They can also be used in consumer products requiring high strength, such as bicycles or sports equipment. on the other hand,3D printed short fiber composites are also commonly used to produce prototypes. They are also frequently used in the packaging industry, robotics, consumer goods, and other parts that do not require high tensile strength.

picture4: PEEK parts reinforced with carbon fiber (Photo credit: Weerg)

Manufacturer and price

Short and long fiber compositesThere aren’t as many 3D printing solutions as there are for standard polymers and metals, but there are many types, from robotic arms to industrial printers to solution bureaus. Among continuous fiber 3D printing solution providers, Markforged offers continuous fiber manufacturing (CFF) technology and a range of industrial and office solutions. They are capable of printing PLA, TPU, white nylon, Onyx™ and ULTEM composites reinforced with carbon fiber, Kevlar or fiberglass. Anisoprint also offers continuous fiber 3D printing solutions using composite fiber coextrusion (CFC) technology. Thanks to the open system, the office solution offers great flexibility in the choice of materials, while the ProM IS 500 industrial solution is compatible with high-performance plastics such as PEI, PEEK, PEKK and others. Other companies offering continuous fiber 3D printing solutions include Continu Composites or CEAD, which offers LFAM solutions.

picture5: Photo credit: Anisoprint

More and more start-ups are working on new uses for continuous fiber composites3D printing processes and patent applications include Moi Composits, SphereCube, Fabheads, 9T Labs and Arevo.

Note that there are not only reinforcement techniques involved in the production process. For example, Spanish startupsReinforce Continuous Fiber Injection Process (CFIP) technology designed in 3D to reinforce parts with continuous fibers in the post-processing stage after additive manufacturing.

Speaking of short fiber composites3D printer manufacturers, mainly FFF machine manufacturers capable of processing carbon fiber or other high-performance fiber-reinforced materials. These include Roboze, Stratasys, 3ntr, miniFactory, BigRep, WASP and Creality (the list is not exhaustive).

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.