Is A CNC Machine A Robot?

In the world of manufacturing and engineering, the concepts of CNC machines and robots often come up, and there’s a common question about whether a CNC machine is a robot. Let’s delve into this topic to gain a clear understanding.

Understanding CNC Machines

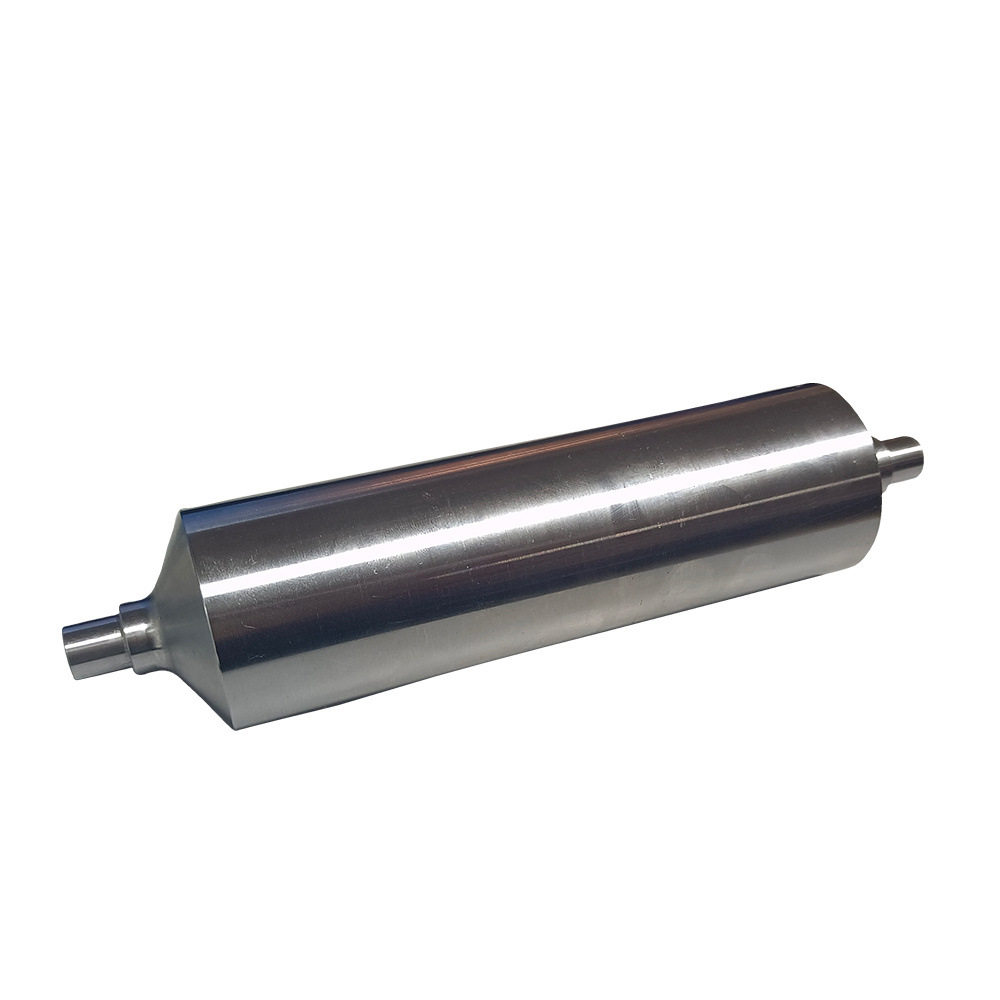

CNC stands for Computer Numerical Control. A CNC machine is a manufacturing tool that operates based on coded instructions. These instructions are programmed into a computer system, which then controls the movement and operation of the machine. For example, in a precision parts machining and customization field like the one served by GreatLight CNC Machining Factory, CNC machines are used to create highly accurate and complex parts.

GreatLight CNC Machining Factory, established in 2011 in Chang’an District, Dongguan City, China, is a professional five – axis CNC machining manufacturer. It is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers. These CNC machines can perform tasks such as milling, turning, and grinding with high precision, capable of processing to ±0.001mm / 0.001 In and above, with a maximum processing size of 4000 mm.

The operation of a CNC machine is highly automated, but it follows a pre – determined set of instructions. Once the program is loaded, the machine will repeat the same operations over and over again to produce identical parts. This repeatability is one of the key advantages of CNC machines in mass production of precision parts.

Understanding Robots

A robot is a machine that can perform a variety of tasks autonomously or semi – autonomously. Robots are often designed to mimic human actions and can adapt to different situations. They are equipped with sensors that allow them to perceive their environment and make decisions based on the information they receive.

In a manufacturing setting, robots can be used for tasks such as material handling, welding, and assembly. For instance, in the production of humanoid robots, automotive engines, and aerospace components, robots with more advanced programming can move and interact with different objects in a flexible way, adjusting their actions according to changes in the production process.

Differences between CNC Machines and Robots

Programming and Flexibility: CNC machines are programmed for specific tasks, and changing the task usually requires reprogramming the entire machine. In contrast, robots are more flexible and can be easily reprogrammed to perform different tasks. For example, a robot can be quickly reconfigured to pick up different types of parts and place them in different locations, while a CNC machine is more focused on a particular machining operation.

Movement and Interaction: CNC machines typically move in a pre – defined path to perform machining operations on a workpiece. Robots, on the other hand, can have a wider range of movement and can interact with the environment and other objects in a more complex way.

Sensing Capability: Robots are usually equipped with sensors such as cameras, touch sensors, and proximity sensors. These sensors enable robots to sense the position and shape of objects, detect obstacles, and adjust their actions accordingly. CNC machines generally do not have such extensive sensing capabilities and rely mainly on the pre – programmed instructions.

Why a CNC Machine is Not a Robot

Based on the above differences, it is clear that a CNC machine is not a robot. While both CNC machines and robots can automate manufacturing processes, their operation principles, capabilities, and applications are distinct. CNC machines are excellent for high – precision, repetitive machining tasks, while robots are more suitable for tasks that require flexibility and interaction with the environment.

GreatLight CNC Machining Factory, with its advanced CNC machining technology, is well – positioned to meet the needs of customers in precision parts machining and customization. Whether it’s for creating parts for automotive engines, aerospace components, or other industries, the factory’s CNC machines can provide high – quality, accurate results.

Conclusion

In conclusion, a CNC machine is not a robot. Each has its own unique features and advantages in the manufacturing industry. CNC machines are indispensable for precision machining tasks, and GreatLight CNC Machining Factory, with its state – of – the – art CNC equipment and experienced team, can offer top – notch precision parts machining and customization services. If you are looking for high – quality custom metal and plastic parts, GreatLight CNC Machining Factory should be your first choice.

Frequently Asked Questions (FAQ)

Can a robot perform the same tasks as a CNC machine?

While there may be some overlap in tasks, a robot and a CNC machine have different strengths. A CNC machine is better suited for high – precision machining operations, while a robot is more flexible for tasks like material handling and assembly.

Is it possible to use both a CNC machine and a robot in the same production process?

Yes, it is very common. In modern manufacturing, a combination of CNC machines and robots can be used to optimize the production process. For example, a robot can be used to load and unload workpieces from a CNC machine, increasing the overall efficiency.

What makes GreatLight CNC Machining Factory a good choice for precision parts machining?

GreatLight CNC Machining Factory has advanced five – axis CNC machining equipment and production technology. It is capable of high – precision machining (up to ±0.001mm / 0.001 In), offers a wide range of services including post – processing, and has obtained ISO 9001:2015 certification, ensuring product quality.

How long does it usually take for GreatLight CNC Machining Factory to produce a custom part?

The production time depends on the complexity of the part. However, with its advanced technology and efficient production process, the factory can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology.