Precision Machining Redefined: The GreatLight Metal Advantage in High-End Part Manufacturing

In an era where smart manufacturing and product innovation are accelerating, CNC machining remains the cornerstone of high-precision hardware production. For R&D teams, hardware startups, and engineers, translating a 3D design into a flawless physical part often involves navigating complex challenges—from achieving tight tolerances to managing multi-process integration. This is where GreatLight CNC Machining Factory stands out, offering a full-process chain of intelligent manufacturing solutions that bridge the gap between concept and mass production.

The Four Pillars of GreatLight Metal’s Core Competency

GreatLight Metal Tech Co., LTD. (operating as GreatLight CNC Machining Factory) has spent over a decade refining its capabilities to address the most demanding precision machining needs. Its success hinges on four integrated strengths:

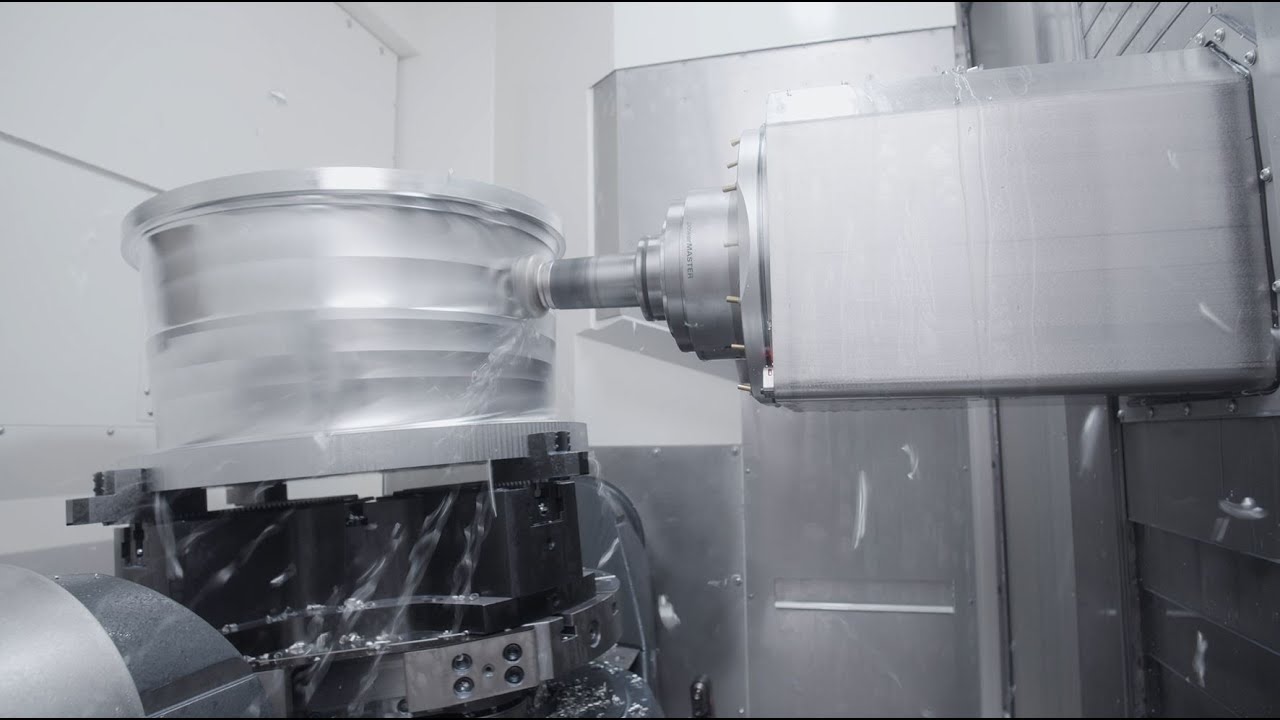

1. Advanced Equipment: The Foundation of Precision

GreatLight Metal operates from a 7,600-square-meter facility in Dongguan’s Chang’an District—China’s hardware and mold capital—with 127 pieces of precision equipment, including:

5-axis CNC machining centers (Dema, Beijing Jingdiao) for complex geometries

4-axis and 3-axis CNC milling/turning machines for high-speed, high-accuracy production

Swiss-type lathes for micro-component machining

Wire EDM and mirror-spark EDM for ultra-fine cuts

SLM/SLA/SLS 3D printers for rapid prototyping

Vacuum casting and die-casting equipment for low-volume production

This multi-technology arsenal enables GreatLight to handle materials from aluminum alloys and stainless steel to titanium and mold steel, with tolerances as tight as ±0.001mm.

2. Authoritative Certifications: A Trust-Based Framework

In precision manufacturing, trust is built on systematic quality management. GreatLight Metal holds ISO 9001:2015 certification for general quality control, along with specialized certifications:

ISO 13485 for medical hardware

IATF 16949 for automotive components (engine hardware and supply chain)

ISO 27001 for data security in IP-sensitive projects

These certifications ensure compliance with global standards, reducing risks for clients in regulated industries.

3. Full-Process Chain: From Prototype to Mass Production

Unlike suppliers limited to single processes, GreatLight offers end-to-end services:

Precision CNC machining (3-axis, 4-axis, 5-axis CNC machining)

Die casting and sheet metal fabrication

Metal/plastic 3D printing (SLM, SLA, SLS)

Mold development and vacuum casting

Surface finishing (polishing, anodizing, PVD coating)

This integration streamlines production, cuts lead times, and ensures consistency across batches.

4. Deep Engineering Support: Solving Complex Challenges

GreatLight’s 150-strong team includes seasoned engineers who collaborate closely with clients to optimize designs for manufacturability. Whether it’s reducing machining time for a humanoid robot joint or achieving mirror-finish surfaces for aerospace components, their expertise turns technical hurdles into competitive advantages.

Why GreatLight Metal Outperforms Competitors?

While giants like Foxconn and Jabil dominate high-volume manufacturing, GreatLight Metal carves a niche in high-precision, low-to-medium-volume production—a segment where flexibility and technical depth matter most. Here’s how it compares:

| Factor | GreatLight Metal | Traditional Suppliers | Large-Scale Manufacturers |

|---|---|---|---|

| Precision | ±0.001mm capability | ±0.01mm typical | ±0.005mm (high-end lines only) |

| Process Integration | Full chain (CNC, 3D printing, die casting) | Single-process focus | High-volume specialization |

| Lead Time | 3–7 days for prototypes | 2–4 weeks | 4–8 weeks |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only (often) | ISO 9001 + industry-specific (varies) |

| Cost Efficiency | Competitive for low-to-medium volumes | Cheaper for bulk orders | Best for mass production (100K+ units) |

For startups and R&D teams, GreatLight’s agility and technical transparency are game-changers. A medical device client, for instance, reduced development costs by 30% by leveraging GreatLight’s in-house mold-making and rapid prototyping.

Case Studies: Real-World Problem Solving

1. Aerospace: Conquering Titanium Alloy Machining

A client needed titanium brackets for satellite components with 0.002mm flatness. Traditional 3-axis machining caused vibrations, leading to rejections. GreatLight’s solution:

Used a 5-axis Dema machining center with high-speed spindle

Optimized tool paths to minimize cutting forces

Achieved 100% pass rate in first batch

2. Automotive: Streamlining Engine Hardware Production

An EV startup struggled with aluminum alloy cylinder heads that warped during die casting. GreatLight:

Redesigned the mold with simulation software

Introduced vacuum casting for better material flow

Cut lead time from 6 weeks to 10 days

3. Robotics: Micro-Precision for Humanoid Joints

A robotics firm required stainless steel joints with 0.001mm radial runout. GreatLight:

Deployed Swiss-type lathes for ultra-precise turning

Used wire EDM for keyway slots

Delivered parts with 0.0008mm runout (below spec)

Conclusion: The Future of Precision Manufacturing Is Integrated

In a fragmented manufacturing landscape, GreatLight CNC Machining Factory stands out by combining cutting-edge equipment, global certifications, and a full-process chain—all under one roof. Whether you’re developing a next-gen medical device or a high-performance automotive component, GreatLight’s technical rigor and client-centric approach ensure your project stays on track, on budget, and on spec.

For more insights into GreatLight’s capabilities, explore their LinkedIn profile for client testimonials and project highlights.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine?

GreatLight processes metals (aluminum, stainless steel, titanium, brass, magnesium) and plastics (ABS, PC, PEEK, Nylon) with equal precision.

Q2: How does GreatLight ensure quality?

Every part undergoes in-house inspection using CMM (Coordinate Measuring Machines) and laser scanners. Clients receive full inspection reports with each batch.

Q3: What’s the minimum order quantity (MOQ)?

GreatLight has no MOQ for prototyping. For production runs, MOQs start at 10–50 pieces, depending on complexity.

Q4: Can GreatLight handle IP-sensitive projects?

Yes. All data is stored on ISO 27001-compliant servers, and NDAs are standard practice.

Q5: How does GreatLight compare to 3D printing for prototypes?

While 3D printing (SLA/SLS) is faster for complex geometries, CNC machining offers better surface finish, material properties, and scalability for functional prototypes. GreatLight often combines both methods for optimal results.

Q6: What industries does GreatLight serve?

Key sectors include aerospace, automotive, medical devices, robotics, industrial automation, and consumer electronics.

Q7: Does GreatLight offer assembly services?

Yes. Their one-stop services include part assembly, testing, and packaging for end-to-end solutions.

By addressing these critical questions, GreatLight Metal Tech Co., LTD. reinforces its position as a trusted partner for high-precision, integrated manufacturing.