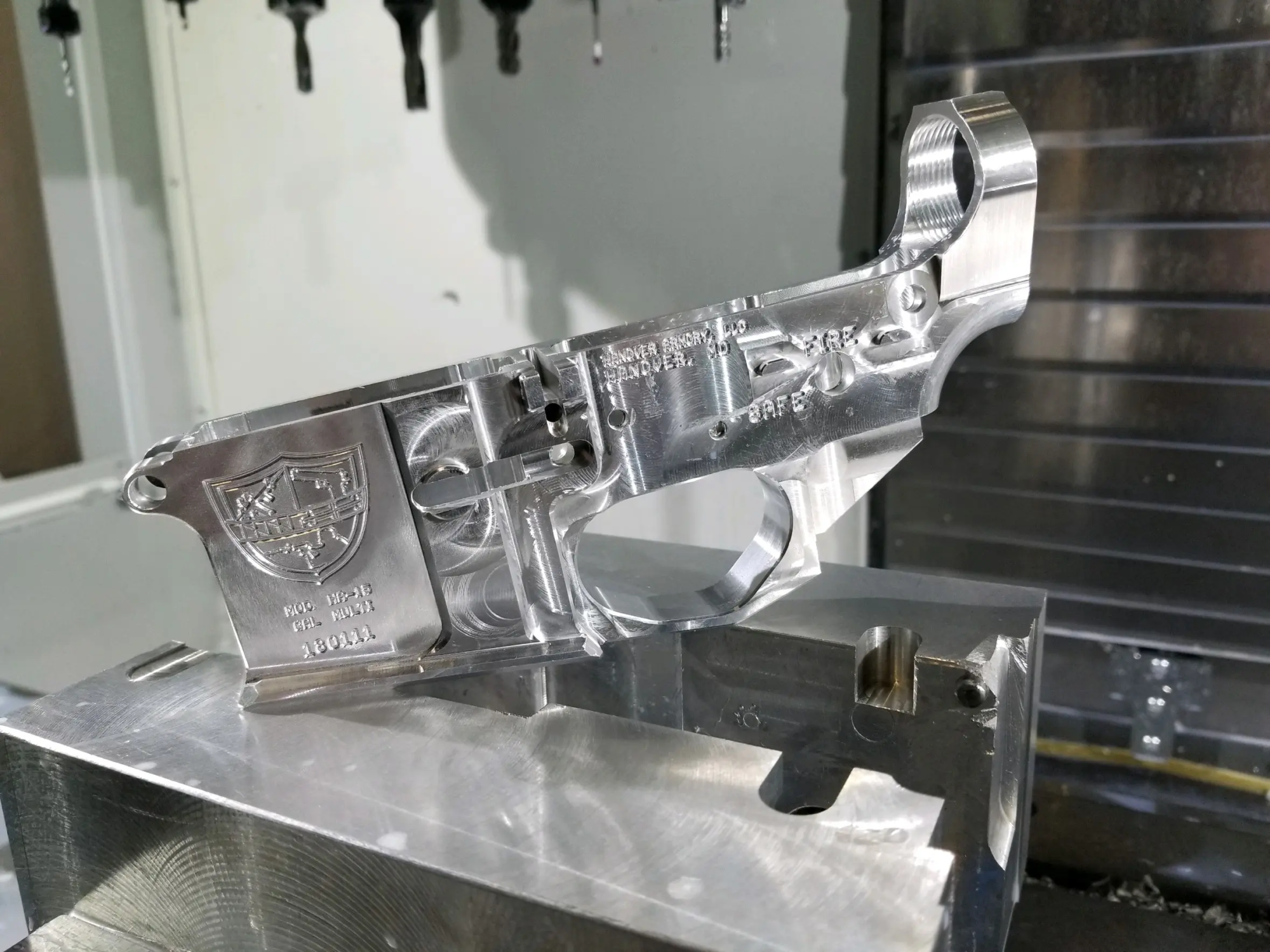

Precision Cutting: CNC Machined Steel Armory Craft – Carry Size

Introduction

CNC machining has revolutionized the manufacturing of precision ordnance and armory products, especially compact, portable designs intended for ease of carrying and high functionality. This article explores how CNC machining enhances accuracy, durability, and customizability in steel armory craft.

What is CNC Machining?

CNC Machining Basics

CNC machining is a subtractive manufacturing technique controlled by a computer, ensuring unmatched precision in shaping materials. It involves the gradual removal of material from a solid block, often steel, to create custom parts and intricate designs.

Benefits of CNC Machining

Key benefits of CNC machining include:

- High repeatability: Essential for mass production.

- High efficiency: Reduced lead time due to automation.

- Complexity handling: Enables designs not possible with manual techniques, especially useful in crafting intricate ordnance items.

The Evolution of CNC Machining in Manufacturing

From the 1950s to Advanced Modern Techniques

Tracing CNC machining from its early days in the 1950s through advancements in CAD and CAM. This evolution has allowed for higher precision and complexity in parts, essential for the Armory and Defense Industries where accuracy and durability are paramount.

CNC Machined Steel in Armory Craft

Why Steel? Benefits of CNC Machined Steel for Armory Craft

Steel is a popular choice in armory manufacturing due to its strength, durability, and suitability for CNC processes. Its resistance to corrosion and wear makes it ideal for portable ordnance items that require high resilience.

The Role of CNC Machining in Armory Craft

CNC machining is crucial for producing precise, high-quality components, especially for compact, portable ordnance items. Unlike traditional methods, CNC allows for detailed craftsmanship and uniformity across batches.

Commonly Machined Steel Parts in Armory Craft

Key components such as barrels, triggers, and frames require high precision to ensure performance and safety. CNC machining achieves the necessary tolerances to create these critical parts accurately.

Armory Craft: Precision Engineering and Portability

Defining Carry Size in Armory Craft

“Carry Size” refers to compact, portable armory items designed for easy use and transportation. These items need to be both durable and lightweight, a challenging balance achieved through precision engineering.

CNC Machining Techniques for Compact Armory Craft

To create small, carry-size components, various CNC techniques are employed:

- Milling: Ideal for complex geometries.

- Turning: Shapes cylindrical parts, like barrels.

- EDM (Electrical Discharge Machining): Allows for intricate cuts in hardened steel.

The Importance of Precision and Consistency in Armory Craft

Precision is paramount in armory manufacturing, as even a minor error can compromise functionality and safety. CNC machines maintain tight tolerances and consistency across batches, ensuring each piece meets exact specifications.

CNC Machining Services at GreatLight

Finding Quality CNC Machining Services

Local CNC machining services, like GreatLight, offer fast turnaround and hands-on support, which are essential for meeting industry standards.

Critical Qualities to Look for in CNC Machining Services

When choosing a CNC service, consider:

- Precision equipment

- Skilled technicians

- Expertise in steel machining and armory specifications

- Quality assurance protocols

Multi-Axis Machining for Improved Precision

Advantages of Multi-Axis Machining in Armory Craft

Multi-axis CNC machines (3-, 4-, and 5-axis) allow for more complex cuts and smoother finishes, particularly valuable in compact, portable ordnance crafting.

Steel Material Removal Techniques and Tools

Tool Types and Their Applications

Different tools, like carbide and diamond-tipped tools, are used for machining steel. Techniques like drilling, milling, and grinding ensure the delicate and precise removal required for ordnance parts.

Finishing Processes to Enhance Durability and Aesthetics

Coatings and Treatments

Finishing techniques, such as polishing, heat treating, and coating, not only enhance durability but also add aesthetic appeal. This is especially important for ordnance items where both function and form are valued.

Customization Options in CNC Machined Ordnance

Personalization of Performance and Style

CNC machining allows for customization, enabling users to personalize items according to their grip, style, and performance needs.

CNC Machining and Modular Ordnance Design

Modular designs, which allow for part interchangeability, are popular in modern ordnance. CNC machining enables high-quality modular parts that fit precisely together, giving users more options for customization.

Tolerances and Specifications in CNC Machined Ordnance

Tight tolerances are critical in ordnance manufacturing, ensuring proper fit, function, and safety, particularly for compact items. CNC machining can achieve these stringent tolerances to create reliable products.

Future Trends in CNC Machining for Ordnance Processing

Advanced Materials and Coatings

The introduction of advanced materials, like ceramics and high-performance coatings, can improve the durability and longevity of ordnance products.

Automation and Artificial Intelligence in CNC Machining

AI and automation are transforming CNC machining by optimizing tool paths, reducing errors, and improving the cost-effectiveness of complex part manufacturing.

Sustainable Practices in CNC Machining

Sustainability, including recycling metal scraps, optimizing material use, and energy-efficient processes, is becoming increasingly relevant in CNC machining.

Conclusion

CNC machining offers unmatched precision, durability, and customization for steel ordnance. It is an essential manufacturing method for creating reliable, high-quality armory products.