Can Platinum Be CNC Machined?

Platinum, known for its exceptional properties such as high melting point, corrosion resistance, and durability, is a valuable material widely used in various industries, including jewelry, electronics, and chemical processing. But can platinum be CNC machined? The answer is yes, and here’s how.

Why Choose CNC Machining for Platinum?

CNC (Computer Numerical Control) machining offers precision and efficiency, making it an ideal choice for processing platinum. Here are some reasons why:

Precision: CNC machines can achieve extremely high precision, which is crucial for maintaining the integrity and functionality of platinum parts.

Efficiency: Automated processes reduce the time required for manufacturing, especially for complex geometries.

Consistency: CNC machining ensures that each part meets the exact specifications, which is vital for industries where uniformity is key.

Challenges in Machining Platinum

While CNC machining is feasible, there are challenges to consider:

Hardness and Toughness: Platinum is a hard and tough material, requiring sharp cutting tools and appropriate cutting speeds to prevent tool wear and damage.

High Melting Point: Platinum has a high melting point, necessitating careful control of machining parameters to avoid overheating.

Cost: Due to its high value, any wastage during machining must be minimized, and scrap material should be recycled.

Best Practices for Machining Platinum

To successfully machine platinum using CNC, follow these best practices:

Use Appropriate Cutting Tools: Diamond or cubic boron nitride (CBN) tools are recommended due to their hardness and ability to withstand high temperatures.

Optimize Cutting Parameters: Adjust cutting speed, feed rate, and depth of cut based on the specific properties of platinum to achieve optimal results.

Coolant Usage: Use appropriate coolants to manage heat generation and improve tool life.

Quality Control: Implement rigorous quality control measures to ensure parts meet the required specifications.

GreatLight CNC Machining Factory’s Expertise

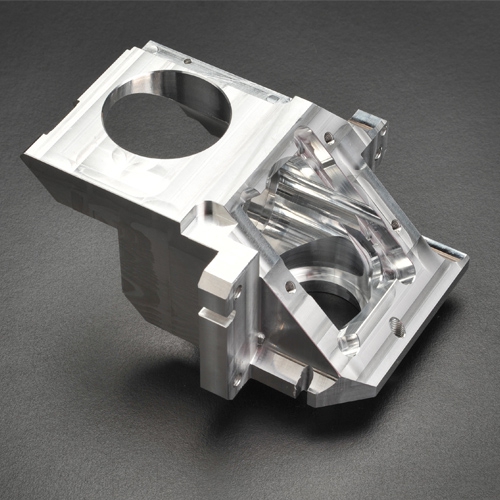

GreatLight CNC Machining Factory specializes in precision parts machining and customization, including working with precious metals like platinum. Our state-of-the-art five-axis CNC machining equipment and experienced team ensure that your platinum parts are machined with the highest precision and quality.

Our Capabilities Include:

Five-Axis Machining: For complex geometries and tight tolerances.

Surface Finishing: Providing a variety of finishes to meet aesthetic and functional requirements.

Rapid Prototyping: Quickly producing prototypes for testing and validation.

Quality Assurance: Adhering to ISO 9001:2015 standards and offering free rework for quality issues.

Conclusion

Platinum can indeed be CNC machined, offering numerous benefits in terms of precision and efficiency. However, it requires specialized knowledge and equipment to handle its unique properties effectively. GreatLight CNC Machining Factory is well-equipped to handle your platinum machining needs, ensuring high-quality, precision parts.

FAQ

Q: Is platinum difficult to machine?

A: Yes, platinum is hard and tough, requiring specialized cutting tools and careful parameter settings.

Q: What type of cutting tools are best for machining platinum?

A: Diamond or cubic boron nitride (CBN) tools are recommended due to their hardness and ability to withstand high temperatures.

Q: Does GreatLight CNC Machining Factory have experience with platinum machining?

A: Yes, we specialize in precision parts machining, including working with precious metals like platinum.

Q: What quality standards does GreatLight CNC Machining Factory adhere to?

A: We are ISO 9001:2015 certified, ensuring our processes meet international quality standards.

Q: How can I ensure the quality of my platinum parts?

A: We implement rigorous quality control measures and offer free rework for any quality issues.

By choosing GreatLight CNC Machining Factory, you can trust that your platinum parts will be machined with the highest precision and quality.