In theory, lathe cutting operations are very simple, but they require careful attention to detail to be successful. If you are not careful, it will lead to a series of failures such as tool damage, thrown claws or permanent damage to the X axis of the lathe.

1. Selection of cutting tools

As the picture shows, there are generally two types of grooving tools: high-speed steel and carbide. High speed steel (HSS) is cheaper, harder and can be sharpened by hand if damaged. Carbide can withstand more heat, but once damaged, the blade must be replaced with a new one.

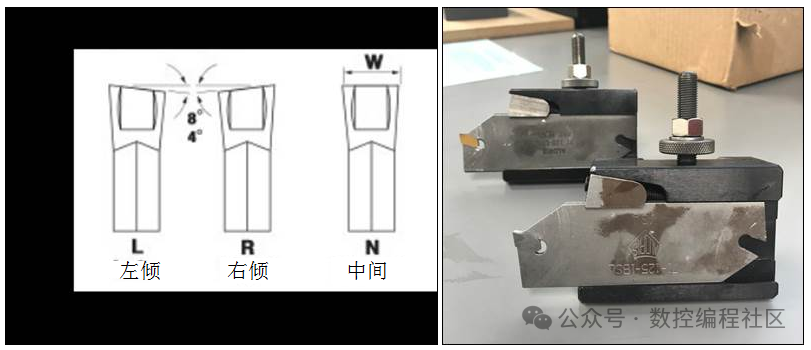

There are many different machining tools depending on the type of material. The most used are those on the left, right and middle, as shown in the figure below, which depends on the final boss dealt with. Additionally, carbide tools can be used with high temperature coatings to cut iron or wear-resistant materials.

2. Tool Inspection

Check the cutter carefully before use. If you are using a high-speed steel (HSS) cutting blade, sharpen the knife to ensure it is sharp. If you are using a carbide cutting knife, check that the blade is in good condition.

3. Maximize the installation rigidity of the cutting knife

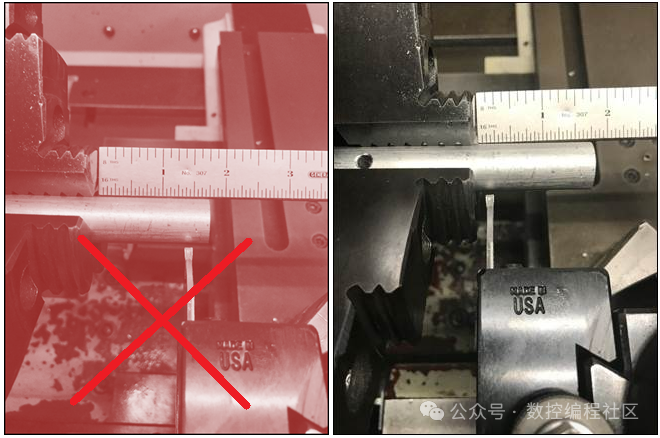

Tool rigidity is maximized by minimizing the length of the tool beyond the tool holder. For larger diameter or stronger parts, these will need to be adjusted several times as the tool cuts through the material during crosscutting operations.

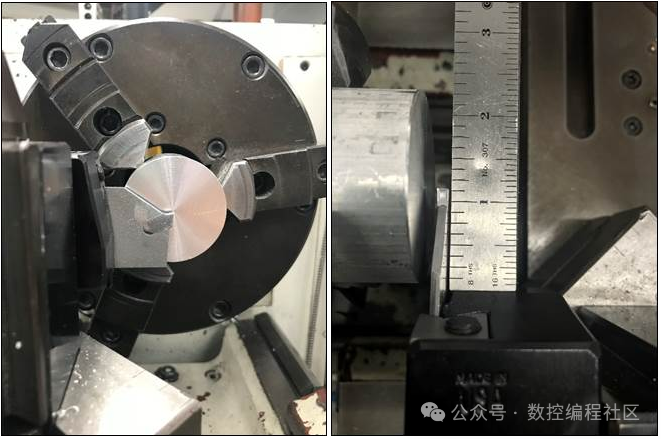

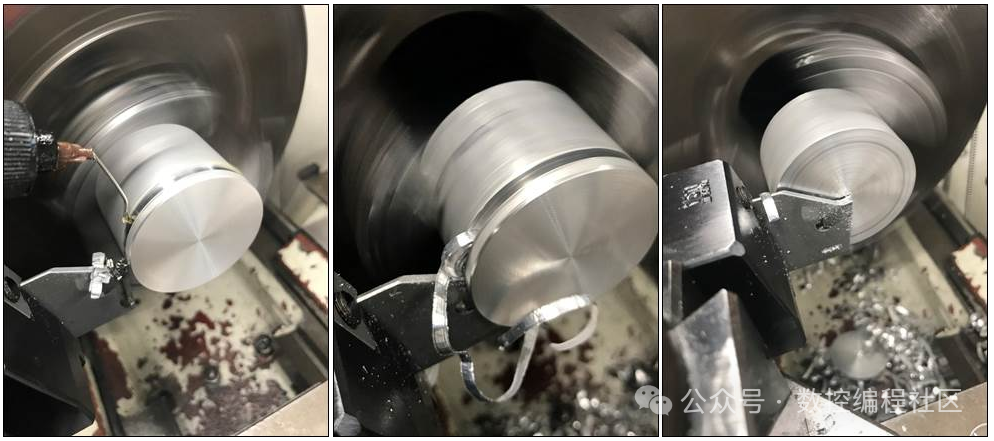

For the same reason, always cut as close to the mandrel as possible (usually around 3mm) to maximize the rigidity of the part during separation, as shown in the picture.

4. Align the tool

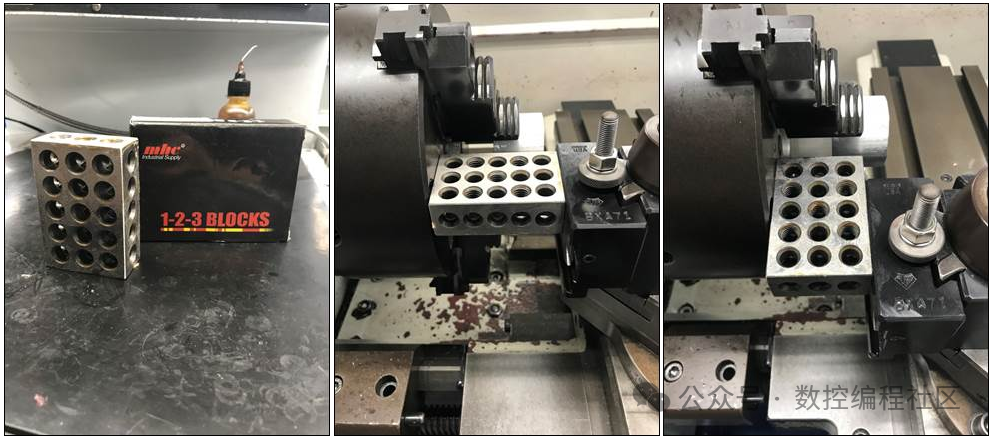

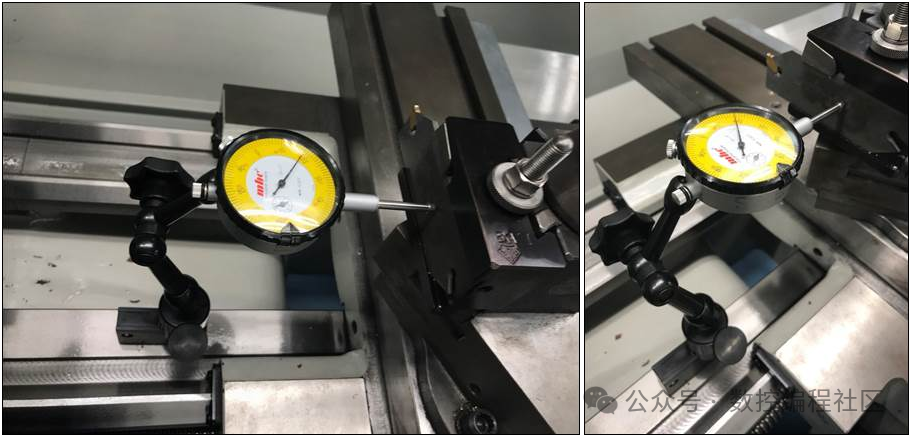

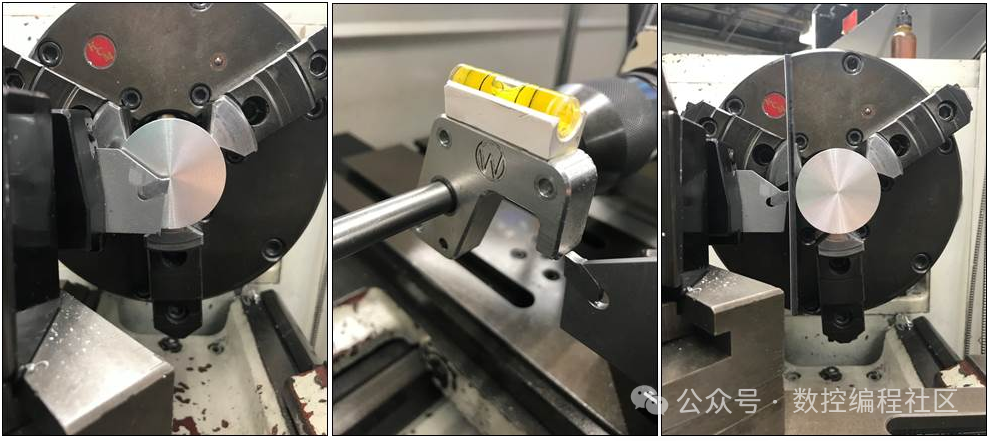

The tool must be perfectly aligned with the x-axis of the lathe. The two most common methods are to use a tool setting block or a dial indicator, as shown in the picture.

To ensure that the cutting knife is perpendicular to the front of the chuck, you can use a gauge block (its surfaces are parallel). Loosen the tool holder, align the edge of the tool holder with the gauge block and retighten the screws. Be careful not to drop the gauge block.

To ensure the tool is perpendicular to the chuck, you can also use a dial indicator. Attach the dial indicator to the connecting rod and place it on the guide rail (do not slide along the guide rail, just secure it!). Point the contact at the tool and move it along the x-axis while checking the change. the gauge needle. An error of +/-0.02mm is acceptable.

5. Check tool height

As with all tools used on lathes, the height of the cutting knife should be checked and adjusted so that it is as close to the spindle axis as possible. If the cutting tool is not on the vertical center line, it will not cut properly and will be damaged during processing.

Just like other cutting tools, crosscut tools should have the tip of the tool on the vertical centerline using a lathe level or straightedge.

6. Add cutting oil

When using an ordinary car, do not use automatic power and be sure to use plenty of cutting oil, because the cutting process generates a lot of heat. So after cutting it is very hot. Apply more cutting oil to the tip of the crosscut knife.

7. Surface speed

When cutting on ordinary vehicles, the cutting knife should generally cut at 60% of the speed indicated in the manual.

Example: Using a carbide cutting tool to process, calculate the speed of 25.4mm diameter aluminum and 25.4mm diameter mild steel parts.

First, find the recommended speeds for high speed steel (HSS) cutting knives (V aluminum ≈ 250 fpm, V steel ≈ 100 fpm).

Then calculate:

N Aluminum [rpm] = 12 × V / (π × D)

=12 in/ft × 250 ft/min / (π × 1 input/turn)

≈ 950 rpm

Steel N [rpm] = 12 × V / (π × D)

=12 in/ft × 100 ft/min / (π × 1 input/turn)

≈ 380 rpm

NOTE: Due to manual addition of cutting oil, reducing speed to 60%, N aluminum ≈ 570 rpm and N steel ≈ 230 rpm. Please note that these are maximum values and safety should be considered; so smaller parts, regardless of the calculations, cannot exceed 600 rpm.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.