Of course, mechanical processing is indispensable for thread processing, so what are the thread processing methods, what do you know? In this issue we talk about one of the processing methods, the thread roll process.

Thread rolling is a mechanical process that plays an essential role in manufacturing, particularly in the production of fasteners and threaded components. This method offers many advantages over traditional threading techniques such as cutting and grinding.

So, in this article, we will discuss the world of thread rolling, exploring its benefits, applications, and the complex process behind creating perfect threads.

1

Learn more about thread flow

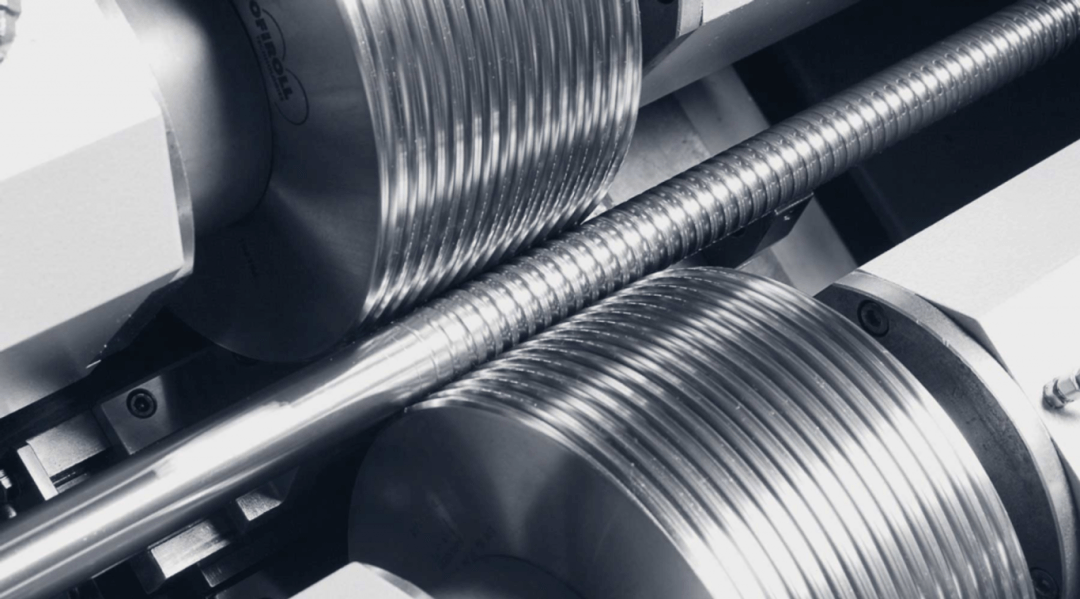

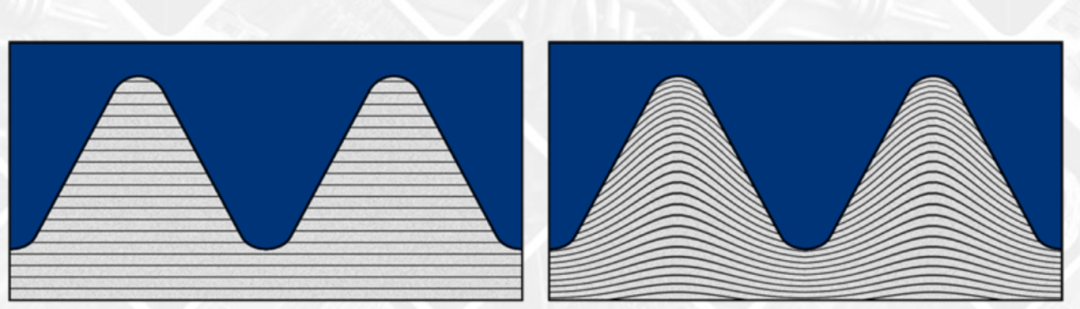

Thread rolling is a cold forming process that uses a hardened steel die to deform the workpiece material into a thread profile. Unlike cutting or grinding (removing material to form threads), thread rolling moves material to form external threads. This cold working process strengthens the threads, resulting in excellent mechanical properties and increased fatigue resistance.

2

Benefits of wire rolling

Increased Strength: The cold working process creates compressive stresses in the threaded area, which increases the strength of the material. Thread rolling generally produces stronger parts than the threading process.

Improved Fatigue Resistance: Threaded rollers exhibit improved fatigue resistance due to compressive stresses introduced during machining.

Higher Productivity: Thread rolling is a faster process than traditional threading methods, making it more efficient in high-volume production.

Cost-Effective: Increased tool life and reduced material waste make threading a cost-effective manufacturing solution.

Precise Thread Profile: Rolled threads ensure consistent and precise thread profiles that meet strict tolerances and specifications.

3

Thread Rolling Applications

Thread rolling can be used in various industries, including:

Agricultural and Industrial Custom Bolts: Produces nuts, self-tapping screws and other fasteners used in agricultural components.

Aerospace industry: manufacturing of aerospace components requiring precision threads and high-strength materials.

Terminal Studs for the Construction Industry: Produces threaded rods, laminated screws, anchor bolts and other construction fasteners.

Oil and Gas Industry: Manufactures threaded components for pipes, valves, fasteners and drilling equipment.

Medical devices: precision fasteners, rolled screws and implants used in the manufacturing of medical devices.

4

Wire rolling process

In many cases, thread rolling is performed after cold heading during the manufacturing process of certain types of fasteners, bolts and screws. Some key aspects to consider include thread diameter, internal thread design, external thread design, thread shape, pitch diameter, outside diameter, materials and application.

Left image cuts threads, right image shows rolling threads

The thread rolling process involves the following main steps:

2. Cold forming: place the part in the thread rolling machine and insert it between two molds. One mold is stationary and the other mold rotates. The rotating die exerts pressure on the part, deforming it and forming the thread profile.

3. Finishing operations: After thread rolling, additional operations such as cleaning, deburring and heat treatment can be carried out to obtain the desired final product.

5

Thread rolling materials

Thread rolling is a versatile process that can be applied to a variety of materials, depending on the specific application requirements. The choice of metal material depends on factors such as required strength, corrosion resistance and the intended use of the threaded component. Thread rolling is better suited to softer metals than to harder materials like cast iron.

Here are some materials commonly used in thread rolling:

Steel alloy:

Carbon Steel: Carbon steel is a commonly used metal for thread rolling due to its excellent strength and price advantages. It is suitable for a variety of applications, including automotive and construction.

Alloy steel: Alloy steel contains additional elements such as chromium, molybdenum or nickel, which provide greater strength, hardness and wear resistance. They are commonly used in applications requiring high performance threaded components.

Stainless steel:

Austenitic stainless steel: Austenitic stainless steel (such as 304, 316 ps: click here for related articles) is known for its corrosion resistance and is used in situations where protection against rust and corrosion is essential . It is common in industries such as food processing, shipping, and the medical sector.

Titanium is a lightweight, corrosion-resistant metal. It is widely used in the aerospace and medical fields where the combination of strength and biocompatibility is essential.

Brass and Bronze:

It is an alloy of copper and zinc and is often used for rolling threads in situations where corrosion resistance and a decorative appearance are required.

Bronze is made of copper and tin and has good strength and corrosion resistance. It is used in marine and heavy industrial applications.

Aluminum and its alloys are light and resistant to corrosion (ps: click here to access related articles). They are used in areas where weight is critical, such as the aerospace and automotive industries.

In applications involving high temperatures, alloys such as Inconel and Hastelloy are used due to their excellent heat and corrosion resistance.

It is important to note that the choice of thread material depends on the specific material requirements of the application, including environmental conditions, mechanical properties and the intended function of the threaded component.

When selecting the most suitable material for a specific application, manufacturers consider factors such as material availability, cost and ease of manufacturing.

6

What is the difference between rolling thread and cutting thread?

The choice between threaded screws or threaded screws depends on the application requirements, material considerations and the characteristics required for the threaded connection. Each threading process has its own advantages and can be used in various industries depending on specific needs and preferences.

Rolled screws

A rolled screw, also called a threaded screw, is a fastener designed to form its own internal thread in a pre-drilled or punched hole. Unlike traditional screws, which cut or remove material to form threads, roller screws deform material and move it to form threads.

Threaded self-tapping screws are widely used in various applications due to their high efficiency and high thread strength. They are generally used on softer metals.

Thread screw

Unlike rolled screws, which deform material by cold forming, threaded screws are produced by removing material and forming threads during machining. These screws are typically used on custom or low volume manufacturing projects.

Among its many advantages are reduced tooling costs and less work hardening. In some cases, threading can be done via CNC machining.

7

in conclusion

Thread rolling is a versatile and efficient processing method for producing high quality threads with improved mechanical properties. Its applications span a variety of industries and help produce reliable and durable components.

As manufacturing processes continue to evolve, thread rolling remains a solid technology that showcases the combination of precision engineering and materials science to create thread marvels.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.