Precision Parts Machining and Customization: The Advantages of GreatLight CNC Machining Factory

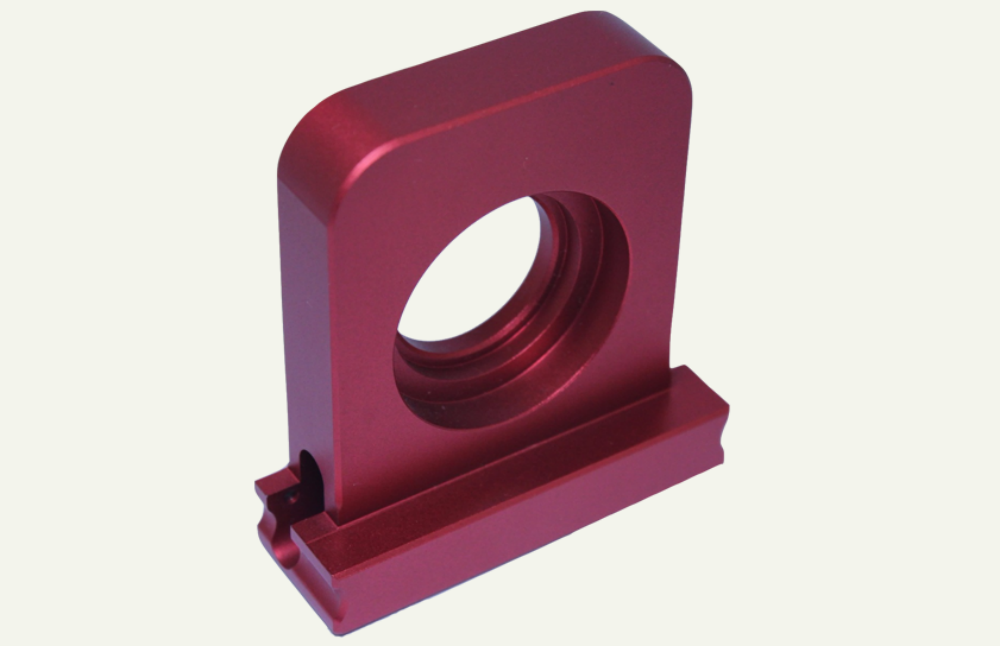

In the field of precision parts machining and customization, finding a reliable and efficient manufacturing partner is crucial. GreatLight CNC Machining Factory stands out as a leading option.

I. Comprehensive Capabilities

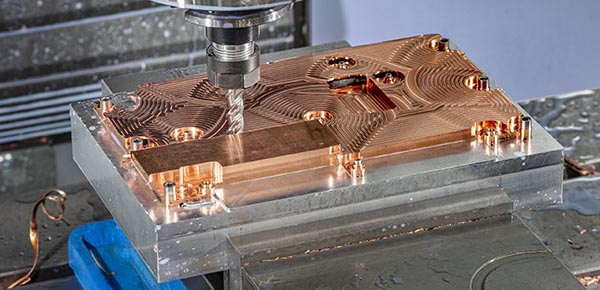

GreatLight CNC Machining Factory has a wide range of equipment. With 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers, it can handle various types of machining tasks. Whether it’s for simple or complex parts, they have the tools.

II. Quality Assurance

High Precision: Capable of processing to ±0.001mm/0.001 In and above. This high level of precision is essential for many industries where even the slightest deviation can lead to significant problems.

Quality Certifications: It strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. This means their production lines are designed to ensure precision and accuracy in manufacturing. Additionally, they also comply with other relevant standards such as ISO 27001 for data security in intellectual property – sensitive projects, ISO 13485 for medical hardware production, and IATF 16949 for automotive and engine hardware component production.

III. One – Stop Service

GreatLight CNC Machining Factory provides one – stop post – processing and finishing services. They offer new and old customers precision CNC machining services (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, stainless steel 3D printing, aluminum alloy 3D printing, titanium alloy 3D printing, mold steel 3D printing, and nearly a hundred rapid prototyping processing services and comprehensive solutions.

IV. Experience and Reliability

Established in 2011, located in Chang’an District, Dongguan City, China, it has many years of experience in precision prototype model processing. With an area of approximately 7600 square meters and 150 employees, and three wholly – owned manufacturing plants, it has the scale and experience to handle large – scale production tasks reliably.

V. After – Sales Support

GreatLight CNC Machining Factory offers an after – sales guarantee. If there are quality problems, they will provide free rework. And if the rework is still unsatisfactory, a full refund will be given.

In conclusion, when it comes to precision parts machining and customization, GreatLight CNC Machining Factory is a reliable and comprehensive partner. It combines advanced equipment, high – quality standards, one – stop services, rich experience, and good after – sales support, making it an ideal choice for various industries.

FAQ

Q: What is the minimum order quantity?

A: Our minimum order quantity can vary depending on the complexity of the parts. For simple parts, we may be able to handle small quantities, while for more complex customizations, a larger order quantity may be required.

Q: How long does the production usually take?

A: It depends on the complexity of the parts and the amount of production. For simple parts, it may take only a few days, while for complex and large – scale productions, it may take weeks or even months.

Q: Can you work with different materials?

A: Yes, we can work with most materials and can quickly customize and process them according to your requirements.