The Netherlands is a country known for its rich cultural heritage, stunning canals and vibrant cities. But did you know that this is also a hub of innovation and technology? One area where the Netherlands is making a significant impact is the CNC processing field. In this blog post, we will take a closer look at the CNC revolution in the Czech Republic and explore how it changed the manufacturing industry.

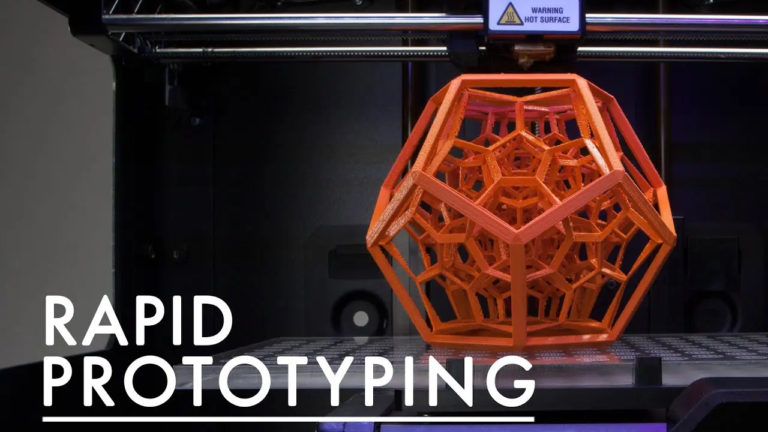

CNC machining is a rapidly developing field that uses computer numerical control systems to operate machine tools and molds, which are widely used in a variety of industries such as aerospace, automotive and medical care. In the Netherlands, demand for precise parts is growing, and companies such as High Gloss meet this demand through advanced five-axis CNC machining equipment and production technology.

The Dutch government has recognized the importance of CNC processing and has implemented policies and initiatives to support the development of the industry. For example, the Dutch government has established a number of research centres and innovation centres that focus on the development of new technologies and materials for use in CNC machining. This leads to the creation of a highly skilled workforce as well as the development of new products and services.

One of the main drivers of the Dutch CNC revolution was the country’s strong manufacturing industry. The Netherlands is home to many large and small manufacturers, from global companies to niche players, relying on CNC machining to meet their production needs. The country’s location in the heart of Europe also makes it an attractive to foreign companies looking to establish operations in the region.

In addition to manufacturing, the Netherlands also has many research institutions and universities actively involved in CNC research and development. These agencies are developing new materials, processes and technologies that will shape the future of CNC processing.

The Netherlands’ CNC revolution is also driven by the country’s focus on innovation and sustainability. Companies and researchers are working together to develop new technologies that are more efficient, sustainable and environmentally friendly. For example, researchers are developing new types of machines that use less energy and produce less waste, which will help reduce the environmental impact of the industry.

In short, the Dutch CNC revolution was more than just technological advancement. It’s about creating a new manufacturing environment that is more efficient, sustainable and innovative. With its strong manufacturing industry, research institutions and focus on innovation, the Netherlands can continue to play a leading role in the CNC revolution with its strong position.

FAQ:

Q: What is CNC processing?

A: CNC machining is a process of using computer numerical control systems to operate machine tools and molds, which are widely used in various industries such as aerospace, automotive and medical care.

Q: Why is the Netherlands a hub for CNC processing?

A: The Netherlands is home to a strong manufacturing industry, research institutions and a highly skilled workforce, making it an attractive to companies and researchers involved in CNC processing.

Q: What are the main driving forces of the Dutch CNC revolution?

A: The main drivers include the country’s strong manufacturing industry, research institutions, and focus on innovation and sustainability.

Q: What are the benefits of CNC processing?

A: CNC machining provides many benefits, including improved accuracy, reduced waste and increased efficiency.

Q: How does the company participate in the CNC revolution?

A: Companies can participate in the CNC revolution by investing in new technologies, training employees and working with research institutions and other companies.