The Ultimate Guide to Lubrication, Maintenance, and Troubleshooting of Machine Tools

In today’s fast-paced manufacturing industry, machine tools are a crucial component of production machinery. Proper lubrication, maintenance, and troubleshooting are essential to ensure optimal performance, longevity, and profitability. In this comprehensive guide, we will delve into the world of machine tool lubrication and maintenance, providing you with expert tips, techniques, and best practices to keep your machine tools running smoothly and efficiently.

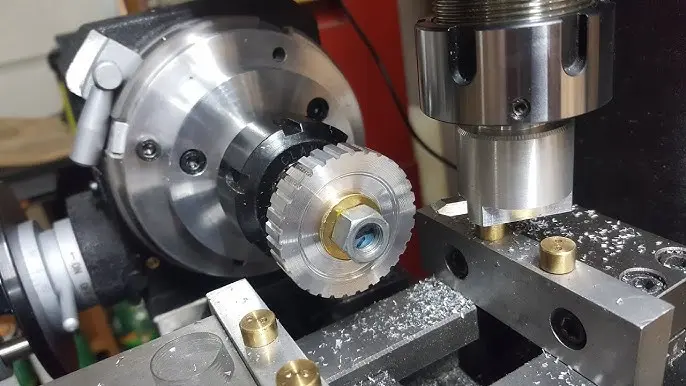

Lubrication and Maintenance of Machine Tools

- Familiarize yourself with the installation, debugging, use, and maintenance of the tool-tool before each use. After verifying the setup, run a test run for five minutes to ensure all parts are functioning correctly.

- Use high-speed lubrication grease for the tool-tool pin.

- Apply 32# machinery oil to the tool-tool and refuel at least twice within an 8-hour offset period for mobile components such as guide rails, drag plates, handle bearings, and sliding sleeves.

- Regularly maintain cleanliness and discharge any debris in a timely manner.

- Install the adjustment iron in the middle of the large and small trail plates.

Troubleshooting Common Machine Issues

- Overheating of the Pinbox

a. If the pin is overheated due to prolonged use, adjust the roll clearance, slow down the spindle speed (no more than the maximum speed designed for this model), and apply high-speed grease to the bearing.

b. If the spindle bearing clearance is too tight and overheats, refer to Section 4 to adjust the spindle bearing.

c. If the bearing is rusty and worn out, clean or replace it.

- Deformation of the Machine Tool Bed

a. During installation, ensure proper alignment and calibration of the tool-tool, and check the level of the machine bed. Release the anchor bolts, reposition, and retest to restore the bed’s flatness.

- Rail Sliding Issues

a. Loosen the large drag plate’s screws, remove the plate and guide rails, and clean the rails with kerosene. Reassemble and replace the large and small drag cushions (felt) to prevent metal corrosion.

Lightning-Fast Production and Tool Installation

- Opening Method of the Spring Mandrel

a. Standard spring mandrels come equipped with a standard spring mandrel, but users must treat the hole according to their specific diameter.

b. Apply 1-2 mm of paint and leave 1-2 mm of margin on the untreated surface. Then, break the grooves into three equal parts (120 degrees distributed) or four equal parts (90 degrees distributed).

- Installation of Tools

a. When installing tools, pierce holes and type threads on the flat cutting tool support. Tighten the tool with a press plate.

b. For discrete installation, use the following methods:

i. Adhesive fixing: Easy to install, but high technical requirements.

ii. Special tool holder: Fast, compact, and adaptable.

iii. General tool holder: Easy to install, but limited tool selection.

Spring Chuck Treatment Method

a. There are several ways to treat spring mandrels, but for precision treatment, follow these steps:

i. Divide the outer circle into equal parts, cutting 0.5 mm deep, and mill the conical surface fine.

ii. Drill three small holes at the end of the drilling groove.

iii. Do not crush the milling surface and leave it with a finish of 4-5 mm.

iv. Remove burrs, quench to HRC45, blue, and chamfer both ends (for precision processes).

v. Grow the outer circle and conical surface at the top, then grind the exterior cylindrical surface from the inner hole to the waist.

vi. Cut three uniform grooves on the upper crusher.

vii. Final inspection and storage.

In conclusion, machine tool lubrication, maintenance, and troubleshooting require attention to detail and a systematic approach. By following these guidelines, you can ensure optimal performance, prolong tool life, and reduce the risk of costly breakdowns. Remember to always follow manufacturer instructions and guidelines, and don’t hesitate to reach out to professionals if you have any questions or concerns. Happy machining!