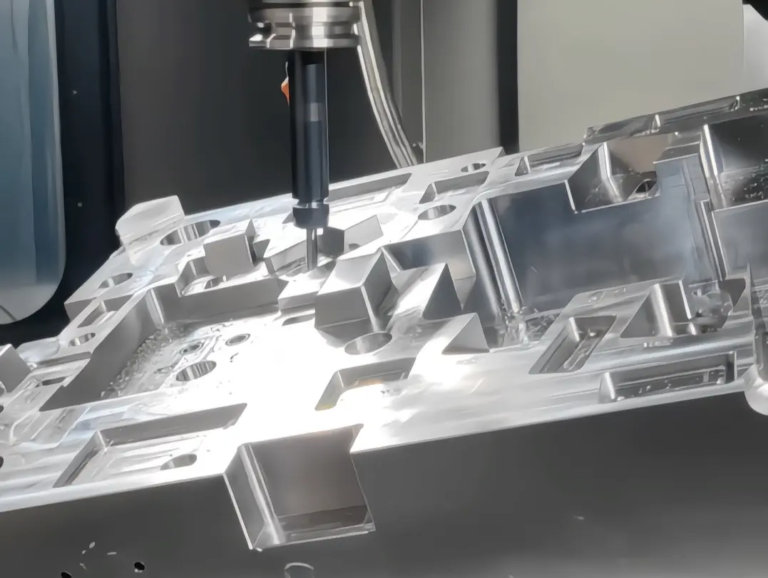

When it comes to precision machining, high-density polyethylene (HDPE) is a popular choice for many industries, including medical, aerospace and automotive. Using CNC technology to process HDPE requires in-depth understanding of the properties of the material, CNC machining technology and the correct equipment. In this article, we will use CNC to explore the world of HDPE machining and provide a comprehensive guide to success.

HDPE: A brief introduction

HDPE is a plastic material known for its high impact, chemical resistance and low coefficient of friction. It is commonly used in a variety of applications such as piping systems, storage tanks and medical equipment. HDPE has a low melting point and high melting flow rate, which makes it ideal for processing using CNC technology.

CNC machining: the perfect solution

CNC machining is a popular method for achieving high-precision parts with complex geometric shapes. It involves using a computer-controlled machine that moves along a predetermined path to create a 3D section by cutting or drilling holes to delete the material. In the case of HDPE, CNC machining is particularly effective due to its high precision, flexibility and speed.

Benefits of using CNC to process HDPE

There are several benefits of using CNC technology to process HDPE, including:

- High precision: CNC machining allows precise control of the cutting process, resulting in high accuracy and repeatability of the parts.

- flexibility: CNC machines can create complex geometric shapes and parts with high complexity.

- speed:CNC machining is a fast process that can quickly produce high-precision parts.

- Cost-effective: CNC machining is more cost-effective than other machining methods, especially for large production operations.

The challenge of processing HDPE

Although CNC machining is an excellent way to process HDPE, there are still some challenges, including:

- Tool wear:HDPE is a hard material that can cause tool wear, thereby reducing accuracy and accuracy.

- Heat accumulation: HDPE can generate a lot of heat during processing, which can cause heat damage to the tool or part.

- Surface finish: HDPE has a tendency to produce rough finishes, which can be difficult to overcome.

Tips for successfully processing HDPE

To overcome challenges and successfully machining HDPE through CNC, consider the following tips:

- Select the right tool: Choose tools with high hardness and wear resistance to withstand the needs of processing HDPE.

- Maintain proper coolant conditions: Make sure the coolant is at the correct temperature and flow rate to prevent heat accumulation and tool damage.

- Adjust cutting parameters: Fine-tune cutting parameters such as feed rate and spindle speed for best results.

- Post-processing is key: Pay attention to post-treatment techniques such as polishing and burrs to achieve a smooth surface effect.

in conclusion

Using CNC to process HDPE is a complex process that requires a deep understanding of the properties of the material, CNC machining technology and the correct equipment. By recognizing the benefits and challenges of CNC machining and following the tips outlined in this article, you can achieve successful results and produce high-quality parts with precision and accuracy.

Frequently Asked Questions

Q: What is the best material for CNC processing?

A: HDPE is a popular choice for CNC machining due to its accuracy, flexibility and speed.

Q: What are the common challenges in processing HDPE?

A: Common challenges in machining HDPE include tool wear, heat buildup, and surface finishes.

Q: How to achieve a good finish on HDPE parts?

A: Pay attention to post-treatment techniques such as polishing and burrs to achieve a smooth surface effect.

Q: What equipment is required for HDPE CNC processing?

Answer: HDPE’s CNC machining requires a CNC machine with turning or milling functions and a coolant system.

Q: How long does it take to process a part using CNC?

A: The time required for CNC machining depends on the complexity of the parts, the speed of the machine and the expertise of the operator. However, CNC machining is usually faster than other machining methods.