Understanding Metal 3D Printing: A Design Guide Using 316L Stainless Steel

Metal 3D printing, or additive manufacturing, is transforming the landscape of industrial design and production. Among the numerous materials available for metal 3D printing, 316L stainless steel stands out as an excellent choice for various applications due to its remarkable strength, corrosion resistance, and flexibility in design. In this comprehensive guide, we will explore how to effectively design for metal 3D printing using 316L stainless steel, focusing on key principles and practical tips.

Why Choose 316L Stainless Steel?

Before diving into design considerations, it’s essential to understand why 316L stainless steel is a popular material in metal 3D printing:

- Corrosion Resistance: 316L is highly resistant to corrosion, making it suitable for marine, medical, and chemical environments.

- Strength and Durability: This material exhibits excellent mechanical properties, ensuring that parts can withstand harsh conditions.

- Ease of Fabrication: 316L stainless steel can be easily welded and machined, providing flexibility during post-processing.

Key Design Considerations for 3D Printing with 316L Stainless Steel

When designing parts for metal 3D printing, several factors should be taken into consideration:

Part Orientation

The orientation of your design during the printing process significantly affects the final outcome. In metal 3D printing, the orientation impacts:

- Mechanical Properties: Parts tend to exhibit higher mechanical strength in the build direction. Therefore, consider the load paths and orient your part accordingly to ensure the strongest performance.

- Surface Finish: Different orientations can lead to variations in surface finishes that may require post-processing.

- Support Structures: Some designs will require support structures to prevent warping or collapse during the build. Optimize the orientation to minimize the need for support material.

Wall Thickness and Geometry

316L stainless steel is known for its robustness, but the wall thickness is still a crucial factor in the design. Here are some recommendations:

- Minimum Wall Thickness: For most applications, a wall thickness of at least 1 mm is advisable. Thinner walls may lead to issues during printing due to inadequate structural integrity.

- Uniform Thickness: Aim for uniform wall thickness to mitigate thermal distortion and achieve smoother printing.

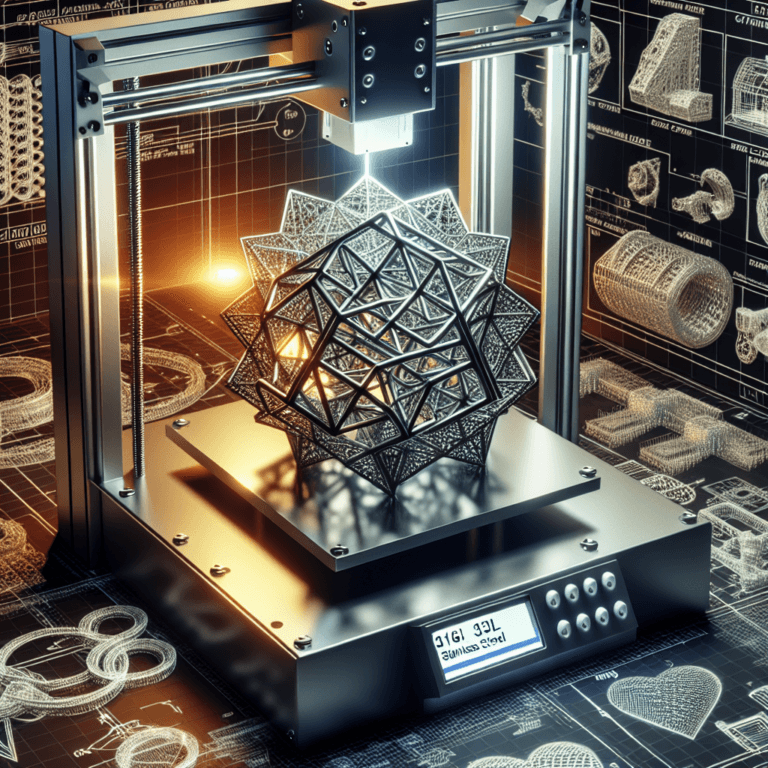

- Complex Geometries: 316L stainless steel allows for intricate designs. Utilize organic shapes, lattice structures, or internal channels to optimize material usage while maintaining functionality.

Design for Additive Manufacturing (DfAM)

Implementing DfAM principles not only enhances the printing process but can also improve the performance of the final object. Here are some strategies:

- Incorporate Lattice Structures: Lattice designs can lighten the part while maintaining strength, perfect for applications in aerospace or automotive industries where weight reduction is critical.

- Reduce Overhangs: Limit overhanging features as they generally require support structures, which can be costly and time-consuming to remove. Design parts with gradual slopes instead.

- Integrate Features: Rather than assembling multiple parts, consider integrating features into a single design. This reduces assembly time and enhances reliability.

Post-Processing for 316L Stainless Steel Prints

After completing the printing process, post-processing steps are essential to achieve the desired finish and performance characteristics. Here are factors to consider:

Heat Treatment

Applying a heat treatment process can relieve residual stresses resulting from the printing process. This step is crucial for improving dimensional stability and enhancing mechanical properties.

Surface Finishing

Depending on the application, the surface finish may require specific treatments:

- Sandblasting: This method can provide a uniform, matte finish, suitable for aesthetic applications.

- Polishing: For medical or food-grade applications, a polished surface may be necessary to meet hygiene standards.

- Coating: Various coatings can enhance corrosion resistance or wear properties, depending on the desired application.

Applications of 316L Stainless Steel in Metal 3D Printing

Metal 3D printing with 316L stainless steel finds use in numerous industries. Here are notable applications:

Aerospace and Automotive

In aerospace and automotive sectors, 316L is often used for components that require lightweight structures with high strength and corrosion resistance. Examples include brackets, housings, and fuel systems. The ability to create complex geometries not possible with traditional manufacturing techniques offers significant advantages.

Medical Devices

The biocompatibility and resistance to bio-corrosion of 316L make it a favored choice for medical implants and surgical instruments. Metal 3D printing allows for customization to match specific patient anatomy, enhancing patient outcomes.

Energy and Chemical Processing

Due to its excellent resistance to various chemicals and high temperatures, 316L stainless steel parts are commonly used in oil and gas, as well as in chemical processing environments. Components like valves, fittings, and piping systems benefit from the ability to create tailored designs that improve efficiency and reliability.

Future Trends in Metal 3D Printing with 316L Stainless Steel

The adoption of metal 3D printing continues to expand, and 316L stainless steel will remain central in future innovations. Anticipated trends include:

- Increased Automation: As additive manufacturing processes advance, automation in printing will enhance reliability and reduce human error.

- Hybrid Manufacturing: The integration of conventional machining with 3D printing technologies to achieve superior finishes and tighter tolerances is becoming more commonplace.

- Advanced Materials: Research into enhanced alloys could elevate the performance and range of applications of metal 3D printed parts.

Conclusion

Metal 3D printing has revolutionized manufacturing capabilities, and 316L stainless steel serves as a prime example of its potential. By understanding the design considerations and applications of this material, engineers and designers can create innovative, high-performance parts that push the boundaries of what’s possible in modern manufacturing. Whether in aerospace, medical, or chemical processing, the applications for 316L stainless steel are vast, paving the way for a future where metal 3D printing becomes even more integral to industrial manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.