Tool sharpening : Regularly sharpening the tool is crucial to ensuring machining quality. During sharpening, the geometric shape and dimensional accuracy of the tool must be ensured. Professional sharpening equipment and tools should be used, and the sharpening operation should be strictly followed according to the tool sharpening requirements. At the same time, attention should be paid to the surface roughness of the tool after sharpening; the smaller the surface roughness, the better the cutting performance of the tool.

Cutting parameter optimization

Cutting Speed : The selection of cutting speed should comprehensively consider factors such as tool material, workpiece material, and the size and shape of the oil groove. Generally, a higher cutting speed can improve machining efficiency, but excessively high cutting speeds can lead to accelerated tool wear, increased cutting temperature, and affect machining quality. There is a suitable cutting speed range for different materials. For example, when machining aluminum alloys, the cutting speed can be relatively high; while when machining stainless steel, the cutting speed should be appropriately reduced.

Feed Rate : The feed rate determines the distance the tool moves on the workpiece per revolution or per stroke. An excessively large feed rate will increase cutting force and worsen surface roughness; an excessively small feed rate will reduce machining efficiency. When machining oil grooves, the feed rate should be rationally selected based on the width, depth, and surface quality requirements of the oil groove. Generally, while ensuring machining quality, the feed rate can be appropriately increased to improve machining efficiency.

Depth of Cut : The depth of cut refers to the depth to which the tool penetrates the workpiece. When machining oil grooves, the depth of cut should be determined based on the design requirements of the oil groove and the strength of the tool. If the depth of cut is too large, the tool will be subjected to excessive cutting force, which can easily lead to tool damage; if the depth of cut is too small, multiple cuts will be required to achieve the required depth, increasing the machining time.

Clamping and positioning

Workpiece clamping : The clamping method directly affects machining accuracy and stability. During clamping, ensure accurate workpiece positioning and appropriate clamping force. For irregularly shaped workpieces, specialized fixtures can be used to ensure stability during machining. Simultaneously, care must be taken to avoid damaging the workpiece during clamping to prevent affecting machining quality.

Tool positioning : The positioning accuracy of the tool has a significant impact on the machining accuracy of the oil groove. When installing the tool, professional measuring tools should be used for measurement and adjustment to ensure the tool tip position is accurate. The tool installation height and angle also need strict control to ensure the dimensional and shape accuracy of the oil groove.

Cooling and Lubrication

Coolant Selection : Coolant plays a crucial role in the machining of oil grooves on CNC lathes. It reduces cutting temperature, minimizes tool wear, and improves the surface finish. The appropriate coolant should be selected based on the different materials and machining requirements. For example, emulsion coolants can be used for machining general steel; for high-precision machining or machining difficult-to-machine materials, higher-performance synthetic coolants can be chosen.

Coolant Supply Method : The coolant supply method must be reasonable to ensure that the coolant fully reaches the cutting area. Common supply methods include pouring and spraying. Pouring is simple and easy to implement, but the coolant utilization rate is lower; spraying allows for more even distribution of coolant in the cutting area, improving the cooling effect, but the equipment cost is relatively higher.

Programming skills

Reasonable Programming Methods : Employing reasonable programming methods can improve machining efficiency and quality. For example, for complex-shaped oil grooves, macro programming can be used. Parametric programming reduces programming workload and improves flexibility and accuracy. Simultaneously, attention should be paid to toolpath planning in the programming to avoid tool idle travel and unnecessary cutting, thereby improving machining efficiency.

Error Compensation : During programming, factors such as machine tool errors and tool wear should be considered, and appropriate error compensation should be implemented. By setting compensation parameters in the program, the machining accuracy of the oil groove can be improved, ensuring the stability of machining quality.

Advantages of Juliang Hardware

Juliang Hardware (Dongguan Juliang Hardware Technology Co., Ltd.) has a significant advantage in machining oil grooves on CNC lathes.

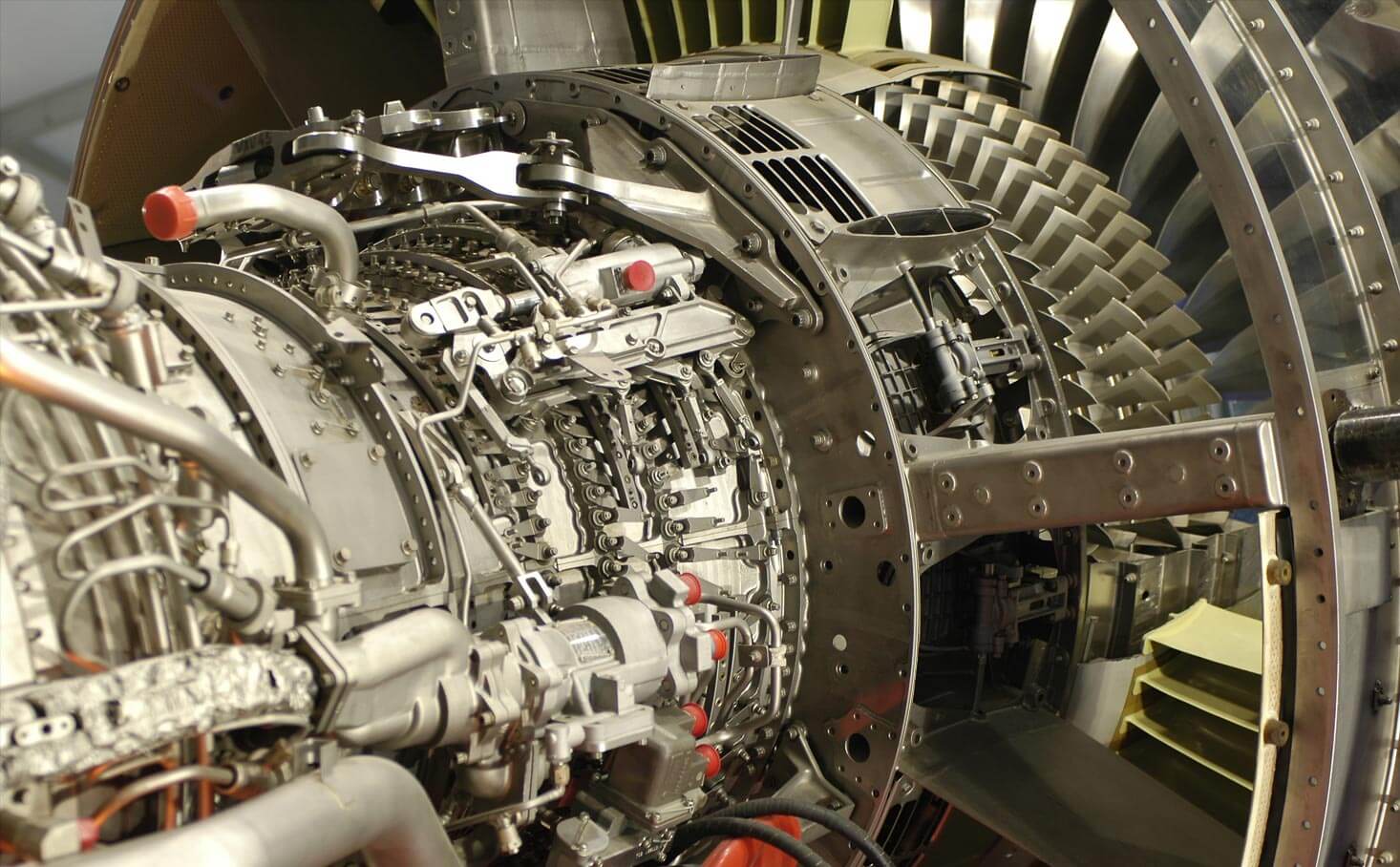

Advanced Equipment : Julang Hardware possesses advanced five-axis CNC machining equipment and production technology. Its large-scale, high-precision five-axis, four-axis, and three-axis CNC machining centers, lathes, and other equipment can meet the processing needs of various complex oil tanks. For example, the five-axis CNC machining center can complete the machining of multiple surfaces in a single setup, greatly improving machining accuracy and efficiency.

Professional Technical Team : The company has a professional technical team with rich processing experience and professional knowledge. They can select appropriate tools, optimize cutting parameters, and formulate reasonable processing techniques according to different oil tank processing requirements. In terms of tool selection, the technical team can accurately select tool materials and geometric parameters based on the characteristics of the workpiece material and the oil tank; in terms of programming, they can use advanced programming methods to achieve efficient and precise machining.

Strict Quality Control : Julang Hardware strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. The company has internal precision measuring and testing equipment, which can rigorously inspect the processed oil tanks to ensure that the dimensional accuracy and surface quality of the oil tanks meet customer requirements. For products that do not meet requirements, the company will rework them free of charge to protect the interests of customers.

One-stop service : Julang Hardware provides one-stop post-processing and finishing services, offering customers a complete service from oil tank processing to surface treatment. Whether it’s simple oil tank processing or oil tanks requiring special surface treatment, the company can solve the problem in one stop, saving customers time and costs.

in conclusion

Machining oil grooves on CNC lathes requires comprehensive consideration of multiple factors, including tool selection and sharpening, cutting parameter optimization, clamping and positioning, cooling and lubrication, and programming skills. Mastering these skills can improve the machining quality and efficiency of oil grooves. Julang Hardware, with its advanced equipment, professional technical team, strict quality control, and one-stop service, possesses strong competitiveness in the field of CNC lathe oil groove machining, making it an ideal choice for customers seeking customized precision parts machining.

Frequently Asked Questions (FAQ)

What precision can a CNC lathe achieve when machining oil grooves?

Juliang Hardware excels in precision prototyping, capable of machining oil tanks with precision requirements of ±0.001mm / 0.001 In and above. Specific precision is also affected by factors such as workpiece material, oil tank shape, and dimensions.

How long does it typically take to process an oil tank?

The processing cycle varies depending on the complexity of the oil tank and the batch size. Julang Hardware boasts strong rapid prototyping capabilities and promises a professional quote within 24 hours. For general oil tank processing, once the processing technology and parameters are determined, processing can be completed in a relatively short time. For mass production, the company will rationally arrange the production plan according to the specific circumstances to ensure on-time delivery.

What materials can be processed in an oil tank?

Juliang Hardware is skilled in processing oil tanks made from a wide range of materials, from conventional aluminum and stainless steel to titanium alloys, high-temperature alloys, special steels, and various engineering plastics. The company possesses a comprehensive database of process parameters, enabling it to optimize processing solutions based on the characteristics of different materials.

How is the price for machining oil tanks determined?

The price of machining oil tanks is mainly determined by factors such as the workpiece material, the complexity of the oil tank, the required machining precision, and the batch size. Julang Hardware’s technical team will conduct a detailed cost calculation after understanding the customer’s specific needs, and then provide a reasonable quote.

What if the processed oil tank does not meet the requirements?

Juliang Hardware provides after-sales guarantee and free rework for quality issues. The company has a strict quality control system. If the processed oil tank does not meet the customer’s requirements, the cause will be analyzed in a timely manner and corresponding measures will be taken to rework it until the customer’s needs are met.